Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● What Is a Rubber Track Undercarriage?

● Key Selection Criteria for Buyers

● Leading Undercarriage Producers Serving Turkey

● Kemer as a Global Crawler Solution Partner

● Typical Applications for Turkish Buyers

● Technology Trends in Rubber Track Undercarriages

● How Kemer Supports OEM Design and Customization

● Sourcing Strategy for International Buyers

● How Rubber Track Undercarriage Manufacturers and Suppliers Add Value

● Integration with Hydraulic Winches and Drives

● Future Outlook for Turkey and Regional Markets

● FAQ

>> 1. What are the advantages of using rubber track undercarriages in Turkey?

>> 2. How do Rubber Track Undercarriage Manufacturers and Suppliers customize solutions for OEMs?

>> 3. What load ranges can typical rubber track undercarriages handle?

>> 4. Why is Turkey an attractive market for Rubber Track Undercarriage Manufacturers and Suppliers?

>> 5. What should buyers check before partnering with a rubber track undercarriage supplier?

Turkey is an increasingly attractive sourcing hub for Rubber Track Undercarriage Manufacturers and Suppliers, driven by a fast‑growing construction and infrastructure market that demands compact, mobile, and low‑ground‑pressure machinery solutions. Global OEMs now look to Turkish and international partners operating in the region to secure reliable rubber track undercarriages, hydraulic drives, and complete crawler systems.

Turkey's construction equipment market has expanded rapidly on the back of large infrastructure projects, urbanization, and post‑earthquake reconstruction, which has increased demand for tracked excavators, loaders, and specialized crawler equipment. This trend directly benefits Rubber Track Undercarriage Manufacturers and Suppliers, as undercarriage systems are core wear components on these machines.

- Earthmoving equipment such as excavators and loaders holds a dominant share in Turkey, intensifying the need for durable undercarriage chains, rollers, sprockets, and rubber track systems.

- Investments in ports, highways, energy facilities, and logistics hubs are attracting both local and international producers of undercarriage and rubber track solutions to serve OEMs and fleet owners.

In this environment, sourcing from experienced Rubber Track Undercarriage Manufacturers and Suppliers is critical to keep machines productive and lifecycle costs under control.

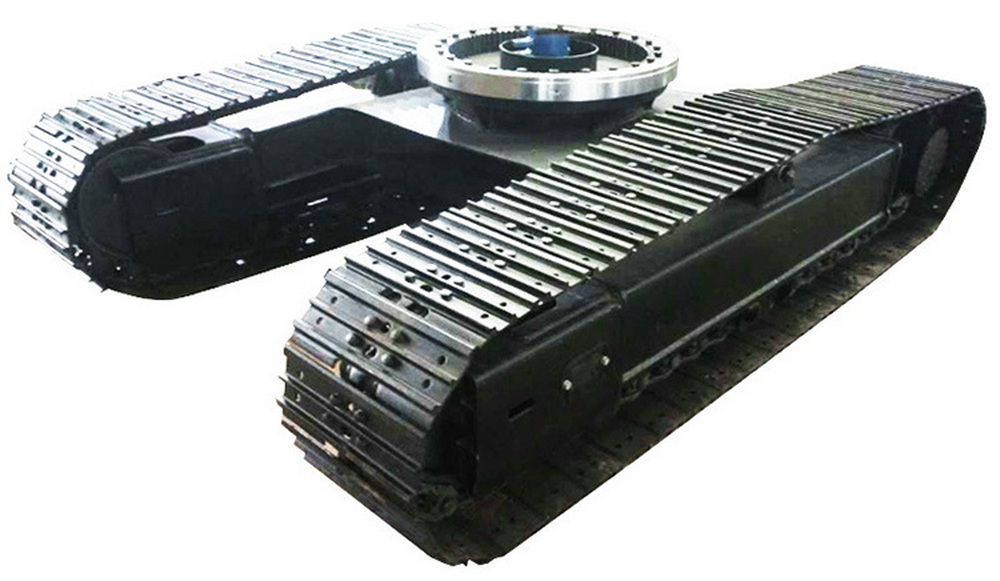

A rubber track undercarriage is a complete crawler system that combines rubber tracks, track frames, rollers, sprockets, idlers, and drive units to support and propel machinery over soft, muddy, or sensitive ground. Compared with steel tracks, rubber track undercarriages reduce ground damage, vibration, and noise, which is ideal for urban projects, agriculture, and compact construction machines.

- Typical applications include mini and midi excavators, skid steers, tracked dumpers, drilling rigs, agricultural sprayers, and special equipment.

- Leading Rubber Track Undercarriage Manufacturers and Suppliers offer systems with load capacities ranging from below 1 ton for compact platforms up to 30 tons or more for heavy crawler carriers and drilling rigs.

Well‑designed rubber track undercarriages give OEMs a plug‑and‑play mobility platform that can be integrated with hydraulic winches, travel drives, and swing drives in a single, optimized package.

When international buyers evaluate Rubber Track Undercarriage Manufacturers and Suppliers in or around Turkey, several technical and commercial criteria determine long‑term success.

- Load capacity and safety factor: The undercarriage must be engineered for the machine's operating weight plus payload, with a suitable safety margin to handle dynamic loads on uneven ground.

- Track design and rubber quality: High‑quality rubber compounds, correct steel cord layout, and optimized tread pattern are essential to achieve long service life with minimal vibration.

Additional aspects include:

- Corrosion protection and sealing of rollers, idlers, and drive sprockets to withstand mud, sand, and water.

- Availability of after‑sales support, spare parts, and technical engineering assistance from Rubber Track Undercarriage Manufacturers and Suppliers to support OEM design projects and field service.

Several undercarriage producers and distributors support the Turkish market by supplying track chains, rollers, sprockets, idlers, and complete crawler modules. Local distributors cooperate with international factories to bring high‑quality undercarriage components to Turkish OEMs and end users. Some groups combine undercarriage parts with other wear components for earthmoving and mining equipment.

In addition to these component producers, global specialists in rubber and steel track undercarriages supply customized crawler bases that can be adapted by Turkish OEMs and system integrators. These partners help local manufacturers shorten development time and upgrade their machines for export markets.

Ningbo Kemer Engineering Machinery Co., Ltd is a specialist manufacturer of steel track undercarriage and rubber crawler undercarriage systems, as well as hydraulic winches and other transmission components. The company operates a modern facility with strong R&D capability, providing integrated track undercarriages and winch solutions to global machinery manufacturers.

- Kemer can supply rubber or steel track undercarriages with load capacities from approximately 1 ton up to 60 tons, suitable for drilling rigs, cranes, crushers, and many other applications.

- As one of the professional Rubber Track Undercarriage Manufacturers and Suppliers, Kemer combines crawler chassis with hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors to deliver complete motion systems for OEM equipment.

For buyers focused on Turkey, working with Kemer offers access to proven crawler technology that can support equipment operating in demanding local construction and infrastructure projects.

The rapid expansion of Turkey's earthmoving and infrastructure sectors creates diverse use cases for undercarriage and track technologies. Whether the machines are produced locally or imported, Rubber Track Undercarriage Manufacturers and Suppliers must tailor their systems to each application scenario.

Key application segments include:

- Urban construction and utilities: Compact excavators and skid steers on rubber track undercarriages help minimize road damage and noise in cities.

- Infrastructure, mining, and energy: Robust crawler bases with higher load capacity support drilling rigs, piling equipment, and mobile crushers on challenging terrain.

In agriculture and forestry, rubber track undercarriages improve flotation on soft soil, protecting crops and increasing working days during wet seasons. Specialized rubber track undercarriage solutions also serve pipeline welding tractors, aerial platforms, and mobile material‑handling equipment.

Technological innovation among Rubber Track Undercarriage Manufacturers and Suppliers is reshaping how machines move over the ground. Advanced rubber compounds, improved steel reinforcement, and optimized tread designs are delivering longer service life and better traction. At the same time, integration with hydraulic and electric drives is enabling more compact, energy‑efficient crawler systems.

- Some undercarriage producers now offer modular rubber track undercarriage platforms that can be quickly customized for different load ranges and wheelbases, shortening OEM development time.

- As electric and hybrid construction machines slowly enter the market, undercarriage and drive system manufacturers are adapting track frames and drive layouts to accommodate batteries and electric motors without sacrificing durability.

Kemer and similar suppliers with strong engineering capabilities are well positioned to help customers transition to these new technologies while maintaining robust tracked mobility.

Because every machine has unique weight distribution, center of gravity, and operating conditions, OEMs often need tailored crawler solutions rather than standard catalog products. As a specialized Rubber Track Undercarriage Manufacturers and Suppliers partner, Kemer supports engineering teams through co‑design and customization services.

- Kemer's engineers can adjust track gauge, wheelbase, roller arrangement, and drive sprocket configuration to match each OEM's chassis layout and performance requirements.

- The company can integrate hydraulic winches, planetary gearboxes, travel drives, winch drives, and swing drives into the same platform, simplifying installation and reducing the number of separate suppliers.

For Turkish machine builders targeting export markets, these integrated solutions help shorten development cycles and improve reliability, which is essential to compete with global brands.

When global buyers source from Rubber Track Undercarriage Manufacturers and Suppliers for machinery destined for Turkey or neighboring regions, a structured sourcing strategy is crucial. The goal is to balance technical performance with cost, lead time, and compliance with local operating conditions.

Recommended steps include:

- Use export directories and industry portals to shortlist undercarriage and rubber track producers that already have experience supplying Turkey or similar markets.

- Evaluate each candidate's certifications, product range, and reference projects, giving preference to suppliers offering both rubber track undercarriages and related drive components for a more integrated solution.

Working with a versatile manufacturer like Kemer allows buyers to secure rubber track undercarriages, hydraulic winches, and drive modules from a single, coordinated partner, simplifying logistics and quality control.

Rubber Track Undercarriage Manufacturers and Suppliers do not just provide parts; they deliver engineering value that influences machine performance, safety, and lifecycle cost. A high‑quality undercarriage directly affects traction, stability, and operator comfort on rough terrain.

- Optimized rubber track profiles and tread patterns reduce slippage, improve climbing ability, and enhance steering response on tight job sites.

- Robust undercarriage components and correct tensioning reduce wear, improve fuel efficiency, and prevent premature failures in demanding working environments.

By collaborating closely with experienced Rubber Track Undercarriage Manufacturers and Suppliers, OEMs can align undercarriage design with real‑world application needs and achieve better total cost of ownership for their fleets.

A major advantage of choosing a full‑line supplier like Kemer is the possibility to integrate rubber track undercarriages with matched hydraulic winches and drive systems. Instead of sourcing undercarriage, winch, and gearbox from separate companies, OEMs receive a complete, pre‑engineered package.

- Planetary gearboxes, travel drives, and swing drives can be sized exactly to the track undercarriage and machine duty cycle.

- Hydraulic winches can be mounted directly on the crawler chassis, creating self‑propelled winch platforms for drilling, lifting, or pulling applications.

This integration reduces engineering risk, simplifies installation, and creates a more compact and efficient overall machine layout.

Turkey's long‑term infrastructure and industrialization plans indicate that demand for tracked equipment will remain strong in the coming years. As contractors adopt more specialized machines for tunneling, renewable energy projects, and high‑density urban construction, the need for advanced rubber track undercarriage solutions will increase.

Rubber Track Undercarriage Manufacturers and Suppliers that can offer energy‑efficient designs, low noise levels, and compatibility with electric drives will gain a stronger position in the Turkish and surrounding markets. Kemer's combination of crawler undercarriage expertise and hydraulic transmission capabilities makes it a strategic partner for OEMs seeking to enter or expand in this region.

Turkey's fast‑growing construction and infrastructure market is driving demand for reliable rubber track and crawler solutions across excavators, loaders, drilling rigs, and special machinery. In this context, experienced Rubber Track Undercarriage Manufacturers and Suppliers that can offer complete undercarriage systems, robust rubber tracks, and integrated hydraulic drives provide OEMs and fleet owners with a decisive competitive advantage.

Kemer stands out as a flexible global partner that designs and manufactures steel and rubber track undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors for a wide range of mobile equipment. By collaborating closely with such technology‑driven suppliers, Turkish and international manufacturers can develop compact, high‑performance tracked machines that meet modern expectations for productivity, reliability, and low ground impact.

Rubber track undercarriages reduce ground damage, vibration, and noise, which is valuable on urban job sites and agricultural land common in Turkey's mixed construction and farming landscape. They also offer better traction on mud and soft soils, improving machine utilization during wet seasons and in regions with challenging terrain.

Manufacturers analyze machine weight, dimensions, and working conditions, then tailor track gauge, wheelbase, roller layout, and sprocket design to suit the OEM's chassis. Integrated suppliers like Kemer additionally combine rubber track undercarriages with hydraulic winches, planetary gearboxes, travel drives, and swing drives to deliver complete drive systems.

Many rubber track undercarriage platforms cover load ranges from around 0.8–1 ton for compact machines up to 30 tons or more for heavier crawler carriers and drilling rigs. Kemer, as one of the Rubber Track Undercarriage Manufacturers and Suppliers, can provide rubber or steel track undercarriages with load capacities from about 1 ton up to 60 tons for applications such as drilling rigs, cranes, and crushers.

Turkey's expanding construction equipment market, driven by infrastructure investments and logistics development, creates sustained demand for tracked earthmoving and material‑handling machines. This demand, combined with the country's ambition to become a regional logistics hub, makes Turkey a strategic destination for undercarriage, rubber track, and crawler system suppliers.

Buyers should confirm product certifications, material quality, and testing standards, as well as the supplier's track record in similar applications and markets. It is also important to review after‑sales capabilities, spare parts availability, and the supplier's ability to support design customization, especially when machines will operate in demanding conditions like those found in Turkey.

https://nbkemer.en.made-in-china.com

https://china-kemer.en.alibaba.com

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Turkey

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Russia

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Indonesia

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Australia

Top Heavy Equipment Undercarriage Manufacturers and Suppliers in Brazil

Top VTS Track System Parts Manufacturers And Suppliers in Hungary

Top VTS Track System Parts Manufacturers And Suppliers in Greece

Top VTS Track System Parts Manufacturers And Suppliers in Luxembourg

Top VTS Track System Parts Manufacturers And Suppliers in Lithuania

Top VTS Track System Parts Manufacturers And Suppliers in Bulgaria