Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

● Understanding the Hydraulic Winch System

● Planning the Hydraulic Winch Hookup

>> Safety Planning Before Installation

● Mounting the Hydraulic Winch

>> Fairlead Position and Rope Path

● Connecting the Hydraulic Power Source

>> Selecting and Mounting the Pump

>> Reservoir, Filtration, and Cooling

● Valve Selection and Circuit Protection

● Hose, Fittings, and Control Hookup

>> Hose and Fitting Best Practices

>> Operator Controls and Ergonomics

● Filling, Bleeding, and Commissioning the Hydraulic Winch

>> Filling and Bleeding the Circuit

● Load Testing and Rope Management

● Safe Operation of a Hydraulic Winch

● Maintenance and Troubleshooting Tips

● FAQs About Hydraulic Winch Hookup

>> 1. How do I select the right hydraulic winch size for my equipment?

>> 2. Can I share one hydraulic circuit between a hydraulic winch and other functions?

>> 3. What happens if my pump is too small for the hydraulic winch?

>> 4. Do I really need a separate case drain line for my hydraulic winch motor?

>> 5. How often should I service my hydraulic winch and hydraulic oil?

Hooking up a hydraulic winch means safely integrating it with the mounting structure, hydraulic power source, and control system so it can deliver reliable pulling power under demanding load conditions. A properly installed hydraulic winch improves productivity, extends component life, and dramatically reduces the risk of leaks, failures, and accidents during heavy pulling tasks.

A hydraulic winch is a complete hydraulic power and motion system, not just a drum with a motor. It converts hydraulic energy from a pump and valve into controlled line pull to move loads smoothly and safely.

Key elements of a typical hydraulic winch installation include:

- Hydraulic winch drum with integrated hydraulic motor, brake, and often a planetary gearbox.

- Hydraulic power source such as a PTO‑driven pump, engine‑driven pump, or self‑contained power pack.

- Hydraulic reservoir, suction line, return line, and filters to keep oil clean and de‑aerated.

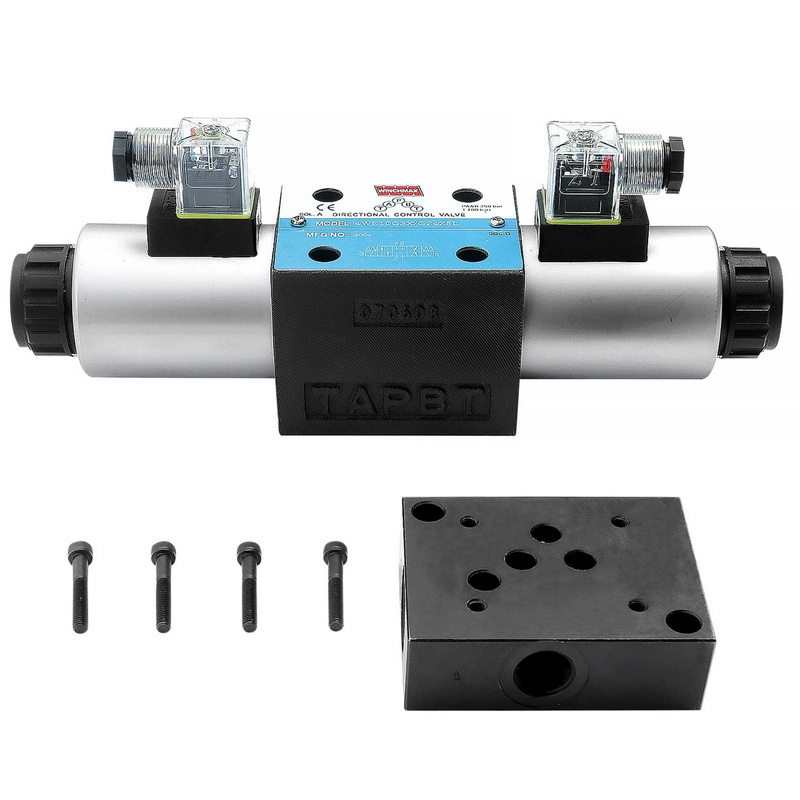

- Directional control valve with relief and, when required, counterbalance or brake valves for controlled operation.

- High‑pressure hoses, fittings, and quick couplers sized and rated for the hydraulic winch duty cycle.

- Mounting base, fairlead, fasteners, and structural supports designed to transfer hydraulic winch pulling forces into the chassis or foundation.

In many tracked carriers, cranes, and marine systems, the hydraulic winch is integrated with other hydraulic components such as travel drives, swing drives, and other actuators, so system matching is essential for stable operation.

Good planning is the foundation of any successful hydraulic winch installation. Rushing into mounting and hose routing without a clear plan usually leads to rework, leaks, or unsafe geometry.

When planning the hookup:

- Define required line pull, line speed, duty cycle, and environmental conditions (mud, saltwater, extreme temperatures).

- Confirm that the hydraulic winch pressure and flow requirements match the available hydraulic power source.

- Review machine drawings or physically inspect the structure to find a strong mounting location for the hydraulic winch.

- Decide whether the hydraulic winch will use a dedicated pump and tank or share an existing machine hydraulic system.

- Sketch the hydraulic circuit from pump to valve to hydraulic winch motor, including return lines, case drain, and filtration.

Safety planning must happen before any hydraulic winch components are bolted on or hoses are connected. Hydraulic systems store energy, and a high‑capacity hydraulic winch can create severe hazards if improperly installed.

Consider these points:

- Identify pinch points, suspended load paths, and operator positions around the hydraulic winch.

- Ensure that all personnel understand lockout and tagout procedures for the hydraulic power source.

- Prepare appropriate personal protective equipment (PPE) such as gloves, eye protection, and safety footwear for the installation crew.

- Plan safe anchor points and rigging paths for later testing and commissioning of the hydraulic winch.

The structural mounting of a hydraulic winch is critical because the entire line pull must be transmitted through the frame, base, or deck. If the structure flexes or deforms, the hydraulic winch performance and safety are compromised.

Best practices for mounting include:

- Use a mounting plate or bracket thickness recommended for the hydraulic winch capacity and frame design.

- Ensure that the mounting surface is flat and rigid to prevent distortion of the hydraulic winch housing.

- Position the hydraulic winch so the rope feeds straight into the fairlead and onto the drum, minimizing side loads.

- Use high‑strength, properly graded bolts with flat washers and locknuts, torqued to the manufacturer's specification.

- Re‑check bolt torque after initial test pulls, as heavy loads can settle the hydraulic winch and mounting structure.

The fairlead guides the rope into the hydraulic winch drum and reduces abrasion. Poor fairlead placement can cause uneven spooling and premature rope damage.

Key considerations:

- Align the fairlead with the centerline of the hydraulic winch drum.

- Maintain a reasonable distance between hydraulic winch and fairlead to ensure smooth rope entry without sharp bends.

- Make sure the rope path from the hydraulic winch to the load is free of sharp corners, protrusions, or heat sources.

- Verify that the fairlead and its fasteners are rated for the full capacity of the hydraulic winch.

The hydraulic circuit is the “circulatory system” of the hydraulic winch. Correct pump selection and plumbing are essential for stable performance.

The pump must supply enough oil flow and pressure for the hydraulic winch under worst‑case load conditions.

Guidelines:

- Check the hydraulic winch documentation for required flow (to achieve target line speed) and required pressure (to achieve rated line pull).

- Select a PTO‑driven or engine‑driven pump whose displacement and speed range can deliver the specified flow at working pressure.

- Mount the pump with proper shaft alignment, using flexible couplings or adapters designed for hydraulic drives.

- Use a short, large‑diameter suction hose from the tank to the pump, minimizing restrictions to avoid cavitation.

Good oil management significantly extends hydraulic winch life and reduces unplanned downtime.

For the hydraulic winch circuit:

- Size the reservoir to hold an adequate volume of oil, often two to three times the pump flow per minute, depending on duty cycle.

- Include a suction strainer (if specified) and a high‑efficiency return filter to remove contamination from the hydraulic winch circuit.

- Position the tank so the return oil enters below the oil level to minimize aeration and foaming.

- Add a cooler if the hydraulic winch will operate at high loads or in hot environments where oil temperature could exceed recommended limits.

The control valve directly impacts how smooth and precise the hydraulic winch feels to the operator. It also plays a key role in protecting the circuit from overpressure or runaway loads.

Important points:

- Choose a directional control valve rated for the maximum flow and pressure specified for the hydraulic winch.

- Integrate a main relief valve sized and set according to the hydraulic winch and system pressure requirements.

- Where loads can overrun the hydraulic winch, use counterbalance or brake valves to prevent uncontrolled descent or back‑driving.

- Consider a pressure‑compensated flow control if you need consistent line speed from the hydraulic winch despite varying loads.

- Follow recommended plumbing for the hydraulic winch case drain, routing it directly back to tank at low backpressure when required.

Once the pump, tank, and valve are defined, the next step is to connect the hydraulic winch with appropriate hoses and fittings, then add operator controls.

Hoses must safely carry high‑pressure oil without causing excessive energy loss or heat buildup.

For a typical hydraulic winch:

- Select hose internal diameter based on expected flow so that fluid velocity stays within recommended limits.

- Use only hoses and fittings rated for at least the system's maximum working pressure, with a suitable safety margin.

- Route hoses along protected zones on the chassis, secured with clamps and abrasion sleeves near edges or potential contact points.

- Allow extra length for suspension travel, articulation, and vibration while avoiding large unsupported loops.

- Keep hoses for the hydraulic winch away from exhaust components and other high‑temperature sources.

Controls should allow precise, intuitive operation of the hydraulic winch while keeping the operator out of danger zones.

Consider:

- Mounting the control lever or joystick where the operator has a clear view of the hydraulic winch and the load path.

- Clear labeling for “winch in,” “winch out,” and any neutral or brake positions.

- Using remote controls (wired or wireless) on recovery vehicles or cranes so operators can stand in a safe position while running the hydraulic winch.

- Including emergency stop capability that immediately stops hydraulic flow to the winch motor in abnormal situations.

After mechanical and hydraulic connections are completed, the system must be correctly filled and de‑aired before the hydraulic winch is loaded.

Proper filling and bleeding prevent cavitation, erratic operation, and premature wear.

Steps:

- Fill the reservoir with the recommended hydraulic oil type and viscosity.

- Confirm that all drain plugs and bleed points on the hydraulic winch and pump are closed as required.

- Start the power source at low speed, keeping the hydraulic winch unloaded, and briefly stroke the control valve to circulate oil.

- Crack fittings or use dedicated bleed screws where specified to release trapped air from the hydraulic winch motor and high points in the circuit.

- Watch for foaming or milky oil in the tank, which may indicate remaining air or contamination.

Before the hydraulic winch is trusted with heavy loads, basic functional testing should confirm correct operation.

Checks include:

- Verify that the hydraulic winch drum rotates in the expected direction for “winch in” and “winch out.”

- Ensure the brake (internal or external) releases and applies correctly, holding the load when the control is in neutral.

- Monitor system pressure, making sure the relief valve setting matches the hydraulic winch rating.

- Listen for abnormal noises from the pump, hydraulic winch motor, or gear train that may indicate misalignment or air ingestion.

Once basic function is verified, move on to controlled load tests and proper rope spooling. Rope handling is a crucial part of hydraulic winch performance.

Use a known, gradually increasing load to qualify the hydraulic winch installation.

Best practices:

- Start with a light load (for example, 10–20% of rated capacity) to check pulling performance and line tracking.

- Increase the load step by step, monitoring pump pressure, motor performance, and hydraulic winch mounting bolts.

- Verify that safety devices such as relief valves and counterbalance valves respond correctly to changing load.

- After the first heavy pulls, inspect the entire installation for leaks, loose fittings, and structural movement.

Correct initial spooling maximizes the life of the rope and the smoothness of the hydraulic winch.

Consider:

- Keeping a minimum of several wraps on the drum at all times, even at maximum extension, to maintain a secure anchor.

- Spooling the first layers of rope under moderate tension so they lay tightly and evenly.

- Avoiding cross‑winding and sudden side pulls that can crush lower layers on the hydraulic winch drum.

- Inspecting rope regularly for kinks, broken strands, or abrasion, and replacing it at the first sign of serious damage.

Even a perfectly installed hydraulic winch can be dangerous if operated carelessly. Safety rules must be followed every time the winch is used.

Key safety guidelines:

- Never exceed the rated capacity of the hydraulic winch, rope, hooks, or shackles.

- Keep bystanders clear of the load path and especially out of the direct line of the rope.

- Avoid sudden shock loads, jerks, or rapid reversals which can spike pressure and damage the hydraulic winch system.

- Use appropriate tag lines, snatch blocks, and rigging to maintain control of the load and reduce side loading.

- Stop immediately if there are unusual sounds, strong vibrations, or visible oil leaks from the hydraulic winch or hoses.

Regular maintenance keeps the hydraulic winch ready for tough work and prevents small issues from becoming critical failures.

Important maintenance steps:

- Periodically check bolt torques on the hydraulic winch, fairlead, and mounting brackets, especially after heavy use.

- Inspect hose assemblies for chafing, blistering, or deep cuts, and replace any damaged lines promptly.

- Monitor oil cleanliness through filter element condition and, when appropriate, oil sampling.

- Lubricate mechanical linkages and inspect seals around the hydraulic winch motor and gearbox for seepage.

- Record operating hours and load conditions so maintenance intervals for the hydraulic winch can be adjusted to real‑world duty cycles.

When troubleshooting performance problems:

- Slow or weak pulling may indicate insufficient flow or low pressure reaching the hydraulic winch.

- Jerky operation may be caused by air in the system, sticking valves, or internal leaks.

- Overheating can point to undersized hoses, excessive relief valve bypassing, or continuous operation at or near maximum capacity.

- Unusual noise from the hydraulic winch may signal mechanical damage, misalignment, or cavitation in the motor.

Hooking up a hydraulic winch is not just a matter of bolting on hardware; it is a system‑level task that involves structural engineering, hydraulic design, and operator safety. By carefully planning the installation, mounting the hydraulic winch on a strong structure, selecting a compatible pump and valve package, and routing hoses correctly, the system can deliver reliable performance shift after shift. Thorough bleeding, step‑by‑step load testing, and disciplined rope management complete the process, ensuring that every hydraulic winch pull is controlled, efficient, and safe in real‑world working conditions.

Choose a hydraulic winch with a rated line pull that comfortably exceeds your maximum expected load, including potential shock factors. Consider duty cycle, mounting space, and available hydraulic power so that the hydraulic winch can reach target line speed at working pressure without overloading the pump or engine.

Yes, many machines share a single hydraulic system between a hydraulic winch and other functions such as booms or travel drives, provided there is enough flow and pressure margin. Use proper valve stacking or flow‑dividing components and ensure that safety‑critical functions still receive priority oil supply when the hydraulic winch is operating.

If the pump cannot deliver enough flow or pressure, the hydraulic winch will pull slowly and may never reach its rated capacity. Running the hydraulic winch under these conditions can cause extended cycle times, overheating, and operator frustration, so the pump and hydraulic winch should be correctly matched during the design stage.

If the motor design specifies a case drain, it is critical to provide a separate low‑pressure return to tank. The case drain allows internal leakage oil to escape, reducing seal stress and internal pressure; without it, the hydraulic winch motor may overheat, blow shaft seals, or suffer premature bearing failure.

Service intervals depend on working conditions, but the hydraulic winch and its oil should be inspected at regular, planned intervals, often aligned with the machine's general maintenance schedule. In harsh environments or heavy‑duty applications, more frequent checks of oil level, filter condition, hose integrity, and rope wear help keep the hydraulic winch operating safely and extend its service life.