Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

● Introduction to Hydraulic Winch on a Jeep

● How a Hydraulic Winch Works on a Jeep

● Planning the Hydraulic Winch Install

● Tools, Parts, and Safety Gear

● Mounting the Hydraulic Winch on the Jeep

>> Integrating with Front Bumpers and Armor

● Connecting the Hydraulic Winch to the Power Steering System

● Dedicated Pump vs Shared Steering Pump

● Hydraulic Controls, Valves, and Line Management

● Bleeding and Testing the Hydraulic System

● Using the Hydraulic Winch for Jeep Recovery

● Maintenance and Troubleshooting

● Safety Tips for Hydraulic Winch Operation

● FAQ

>> 1. How does a hydraulic winch differ from an electric winch on a Jeep?

>> 2. Can a stock power steering pump reliably run a hydraulic winch?

>> 3. Do I need a cooler for my hydraulic winch system?

>> 4. Is a hydraulic winch suitable for daily-driven Jeeps?

>> 5. How often should I service a hydraulic winch on a Jeep?

Installing a hydraulic winch on a Jeep transforms it into a serious recovery tool that can handle long, heavy pulls with confidence. A well-designed hydraulic winch system uses the vehicle's hydraulic power to provide consistent, continuous-duty performance on demanding terrain worldwide.

A hydraulic winch is powered by pressurized fluid from a pump, usually the power steering pump or a dedicated hydraulic pump on the Jeep. Unlike an electric winch that draws heavy current from the battery, a hydraulic winch depends on engine-driven hydraulic power, allowing extended recovery operations without draining the vehicle's electrical system.[1]

For global off-road users, a hydraulic winch is especially attractive because it:

- Delivers continuous-duty pulling for long recoveries without electrical overheating.[1]

- Performs reliably in wet, muddy, and extremely cold conditions that can challenge electric systems.[1]

- Reduces stress on the battery and alternator while still offering strong, controllable line pull on the trail.[1]

A hydraulic winch converts hydraulic energy into mechanical pulling power at the winch drum. The pump pressurizes hydraulic fluid, which travels through hoses into the hydraulic winch motor, turning the drum to reel in or pay out the winch line under control.[2][1]

On most Jeep setups, the hydraulic winch is plumbed either into the power steering circuit or into a dedicated hydraulic circuit with its own reservoir and cooler. When the control valve is activated, fluid is directed through the hydraulic winch motor to rotate the drum, and the return flow goes back to the steering gear or reservoir, completing the hydraulic loop.[3][4][5][2]

Proper planning is essential before bolting a hydraulic winch onto a Jeep, especially if the vehicle is used for global expeditions or professional recovery work. Planning helps ensure the hydraulic winch integrates with steering, cooling, suspension, and front-end armor.[2][3]

Key planning steps include:

- Matching winch capacity to Jeep weight: Choose a hydraulic winch rated at least 1.5 times the Jeep's gross weight once fuel, passengers, and cargo are included.[1]

- Evaluating steering and pump configuration: Decide if the hydraulic winch will share the factory power steering pump or use an upgraded or dedicated pump based on tire size, suspension, and expected recovery frequency.[4][3]

- Selecting a suitable bumper and mounting plate: Ensure the bumper or winch plate is rated to handle the loads a hydraulic winch can exert and bolts directly to strong frame points.[2][1]

Because a hydraulic winch involves both mechanical mounting and fluid routing, having the right tools and components ready saves time and prevents leaks. Collect everything before you start to avoid mid-project delays.[5][2]

Typical tools:

- Metric and SAE socket sets, open-end wrenches, torque wrench, and any Torx or hex drivers needed for the Jeep's bumper hardware.[2]

- Drill and bits for any necessary frame or plate mounting holes within the guidelines of the winch and bumper manufacturers.[2]

- Line wrenches (flare nut wrenches) for hydraulic fittings to reduce the risk of rounding or damaging high-pressure connections.[5]

Common parts and supplies:

- High-pressure hydraulic hose rated above the pump's maximum pressure, plus correct JIC, ORB, or other required fittings.[5][2]

- Thread sealant or tape compatible with hydraulic systems, and clamps or P-clips to secure hoses along the frame rails safely.[5][2]

- Quality recovery accessories like tree-saver straps, rated shackles, soft shackles, and snatch blocks that complement the hydraulic winch system.[6][7]

Safety gear:

- Heavy-duty gloves and eye protection to handle the line, fittings, and steel components safely.[7][6]

- Wheel chocks, jack stands, or ramps to secure the Jeep while working underneath or around the front frame.[6][7]

Winch mounting is all about strength and alignment. The hydraulic winch must be firmly attached to a plate or bumper that ties directly into the Jeep's frame. Loose or weak mounts can lead to frame damage, misalignment, or failure under heavy load.[1][2]

General mounting steps:

- Test-fit the winch plate: Position the winch mounting plate on the frame or bumper and loosely install bolts to ensure holes line up and steering or radiator components are not obstructed.[2]

- Bolt the hydraulic winch to the plate: Set the winch on the plate, install all mounting bolts with lock washers or locking nuts, and tighten to the torque values recommended by the manufacturer.[2]

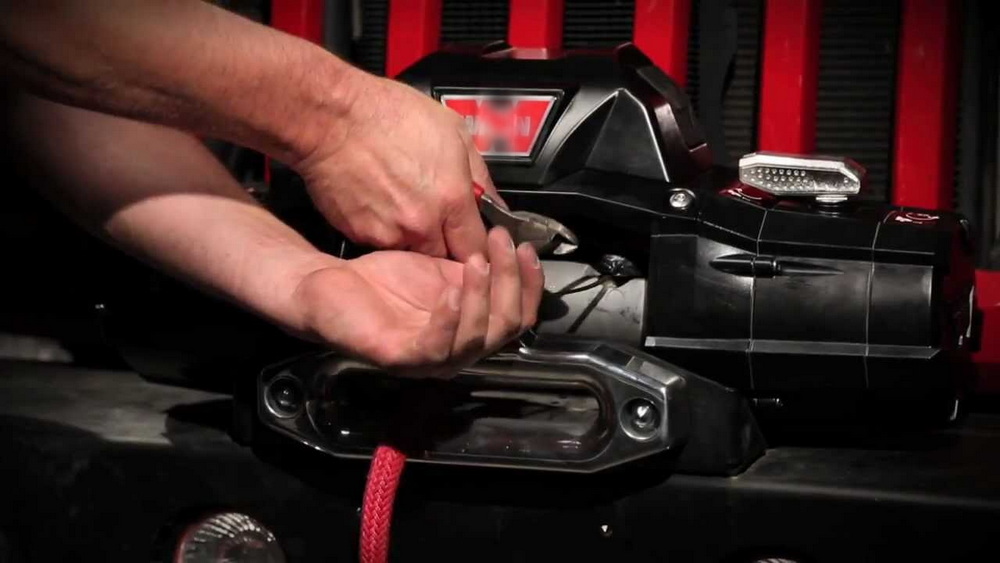

- Install and align the fairlead: Fit a roller or hawse fairlead to the bumper or plate, verifying that the opening is centered with the hydraulic winch drum to reduce side loading on the line.[6][2]

Many Jeep owners choose a winch-ready front bumper or armor system that is specifically rated for recovery loads. When pairing such components with a hydraulic winch, alignment and load sharing are crucial.[1]

Good integration practices:

- Remove factory tow hooks or brush guards that interfere with the winch plate, and use new high-grade bolts where required.[2]

- Confirm that the bumper, winch plate, and frame all share the load path so forces from the hydraulic winch are transmitted directly into the chassis.[1][2]

- Recheck all torque values after a short period of actual winch use, as vibrations and initial use sometimes settle fasteners.[8][6]

The most common configuration for a Jeep hydraulic winch is to tap into the power steering circuit. This allows the hydraulic winch to function as long as the engine is running and the pump is producing pressure.[3][4][5]

Typical plumbing layout:

- Pump pressure port → hydraulic winch inlet → hydraulic winch outlet → steering gear inlet → return line to reservoir.[5]

- High-pressure hoses and adapters are used to route fluid through the hydraulic winch while keeping steering performance acceptable during normal driving.[5][2]

Basic connection steps:

- Install adapters on the steering pump: Remove the factory pressure line, install kit-supplied adapters or T-fittings, and reconnect the line in a way that directs flow to the hydraulic winch before going to the steering gear.[5][2]

- Route hoses safely: Run hydraulic hoses along the frame rails, avoiding sharp edges, suspension movement paths, hot exhaust components, and rotating parts like the driveshaft or fan.[9][2]

- Connect return lines: Ensure the return from the hydraulic winch and steering gear go back into the reservoir smoothly, with minimal restrictions, to prevent cavitation or foaming.[5]

Choosing between a shared steering pump and a dedicated hydraulic pump affects both performance and complexity of the hydraulic winch installation.[4][3]

Shared steering pump characteristics:

- Easier installation because it uses the existing power steering pump and reservoir circuit.[5]

- Lower cost, but heavy hydraulic winch use can strain the pump, potentially affecting steering feel when winching under high load.[3][4]

Dedicated hydraulic pump characteristics:

- Requires mounting an extra pump on the engine, transfer case, or PTO output, along with a separate reservoir and possibly a cooler.[9][3]

- Provides more consistent hydraulic winch performance, often with higher available flow and pressure, and leaves steering assist largely unaffected.[4][3]

For Jeeps that frequently tow, recover other vehicles, or operate in commercial or expedition roles, a dedicated pump can be a worthwhile upgrade for the hydraulic winch system.[3][4]

Control over the hydraulic winch comes from a directional valve that manages fluid flow for line-in, line-out, and neutral. Depending on the kit, the valve may be manually operated or controlled by electric solenoids linked to switches or a remote.[1][5]

Important control considerations:

- Mount the control valve in a protected but accessible location, such as in the engine bay or near the frame rail behind the bumper.[7][6]

- Use suitable hose sizes and minimal tight bends to reduce pressure drop, ensuring the hydraulic winch maintains good line speed and pulling power.[5]

Many modern hydraulic winch systems integrate low-voltage control circuits for in-cab switches or wireless remotes. Following the provided wiring diagram carefully and protecting all connections from moisture and abrasion ensures reliable actuation of the hydraulic winch controls.[2][1]

After plumbing the hydraulic winch, the hydraulic circuit must be bled to remove air and tested for leaks. Air in the system can cause noisy operation, reduced performance, and erratic steering.[9][5]

Basic bleeding and testing steps:

- Fill the reservoir to the recommended level with the correct fluid and cycle the steering from lock to lock to help purge air.[9]

- With the Jeep safely supported and the parking brake engaged, briefly activate the hydraulic winch in both directions while watching for bubbles in the reservoir and listening for pump noise.[9][5]

- Inspect all hose connections and fittings under light winch load, checking for seepage or leaks that must be tightened or resealed.[5]

Once the system runs quietly and smoothly, perform a controlled test pull on a gentle incline or against a stable anchor to verify hydraulic winch operation under real load.[7][6]

A hydraulic winch is a powerful tool, and proper technique keeps recoveries efficient and safe. Understanding how to rig and operate the hydraulic winch is as important as installing it correctly.[6][7]

Basic recovery sequence:

- Engage free-spool and pull out the line while maintaining light tension to keep it from bunching or tangling on the drum.[7][6]

- Connect to a solid anchor using a tree-saver strap and rated shackles, then take up slack with the hydraulic winch before starting the main pull.[6][7]

- Stand well clear of the line, keep bystanders away, and operate the hydraulic winch smoothly, pausing periodically to inspect the rigging.[8][6]

Advanced recovery practices:

- Use snatch blocks to change the pulling direction or to double the effective pulling power of the hydraulic winch on heavy or stuck loads.[8][6]

- Maintain a steady engine speed to support adequate hydraulic pressure and flow to the hydraulic winch, especially when the Jeep is also climbing or steering.[10][1]

Routine maintenance extends the life of both the hydraulic winch and the Jeep's hydraulic components. A well-maintained hydraulic winch is more likely to perform when needed in remote environments.[7][6]

Maintenance checklist:

- Regularly inspect hoses, fittings, and the hydraulic winch motor body for signs of leaks, cracking, chafing, or corrosion.[9][5]

- Monitor fluid levels and fluid condition, replacing hydraulic fluid at intervals recommended by the pump or steering component manufacturer, especially after heavy winch use.[9][5]

- Check the winch cable or synthetic rope for frays, flat spots, or damage, and respool under moderate tension to keep layers tight and even.[6][7]

Troubleshooting common issues:

- Slow or weak hydraulic winch performance often points to low fluid level, air in the system, clogged filters, or an undersized or failing pump.[1][5]

- Hard steering or steering loss when the hydraulic winch is in use can indicate that the shared pump is overloaded or that the plumbing is incorrectly routed.[4][3][5]

Addressing these issues promptly prevents more expensive damage to pumps, steering gears, and the hydraulic winch itself.[9][5]

Because a hydraulic winch can apply tremendous force, safety must always be the highest priority during recovery. Following a few habits will significantly reduce risks.[8][6]

Key safety practices:

- Never step over a tensioned winch line, and keep everyone well outside the potential snap-back zone should a component fail.[8][6]

- Use a line damper or recovery blanket placed over the cable to absorb energy if the line breaks.[7][6]

- Stop immediately if you hear unusual noises, see jerky movement, or notice fitting leaks, and inspect the entire hydraulic winch setup before continuing.[6][7]

Proper training, clear communication with spotters, and respect for the power of a hydraulic winch help ensure that recoveries end without injuries or equipment damage.[8][6]

A hydraulic winch system turns a Jeep into a continuous-duty recovery platform capable of tackling demanding global conditions, from remote trails to professional work sites. By taking time to plan the installation, mounting the winch correctly, plumbing and bleeding the hydraulic circuit carefully, and respecting safety and maintenance practices, a hydraulic winch can deliver years of smooth, reliable pulling power that often surpasses comparable electric systems for long-duration recoveries.[7][6][2][1]

A hydraulic winch uses engine-driven hydraulic pressure, while an electric winch relies on the Jeep's electrical system and battery for power. Because the pump is mechanically driven, a hydraulic winch can usually run longer under heavy load without overheating, making it well suited to extended Jeep recoveries.[10][1]

A stock power steering pump can run a hydraulic winch for light to moderate use, but it may struggle under frequent or heavy recovery loads, especially with large tires and upgraded steering components. Many serious off-road users upgrade the pump or install a dedicated unit to ensure consistent steering assist and strong hydraulic winch performance.[3][4][5]

A cooler is strongly recommended when using a hydraulic winch for long or repeated pulls because hydraulic fluid heats up quickly under load. Keeping fluid temperatures controlled helps maintain line speed, protects seals, and extends the lifespan of both the pump and the hydraulic winch motor on a hard-working Jeep.[9][5]

A properly designed and installed hydraulic winch system can work very well on a daily-driven Jeep, as long as the hydraulic circuit is balanced and steering performance remains smooth. With correct routing, cooling, and pump sizing, the hydraulic winch stays ready for weekend or expedition recoveries without compromising normal day-to-day driving.[4][3][1]

Service frequency depends on use, but many owners inspect hoses, fittings, fluid levels, and the hydraulic winch line before and after serious off-road trips. At least once or twice a year, a more complete service including fluid changes, hardware retorquing, and careful line inspection helps keep the hydraulic winch dependable for global off-road adventures.[7][6]

[1](https://www.extremeterrain.com/jeep-wrangler-winches-explained.html)

[2](https://www.mywinch.com/help/MileMarkerHydraulicWinchInstallation.htm)

[3](https://www.jlwranglerforums.com/forum/threads/hydraulic-winch.146227/)

[4](https://naxja.org/threads/hydraulic-winch.940495/)

[5](https://www.tractorbynet.com/forums/threads/hydraulic-winch-hook-up.96792/)

[6](https://dixie4wheeldrive.com/a-step-by-step-guide-to-using-a-winch-in-vehicle-recovery-situations/)

[7](https://www.rhinousainc.com/blogs/news/how-to-use-a-winch-to-recover-a-jeep)

[8](https://wranglertjforum.com/threads/winching-without-the-worry.271/)

[9](https://www.youtube.com/watch?v=k0MvLERCTgM)

[10](https://www.youtube.com/watch?v=3VGKcULQQn8)

[11](https://www.youtube.com/watch%3Fv=FRv-BK4duvs)

[12](https://www.youtube.com/watch?v=D2eBajz2E-o)