Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Why South Korea Matters for Rubber Track Undercarriages

● Role of Rubber Track Undercarriage Manufacturers and Suppliers

● South Korean Market Drivers for Rubber Track Undercarriages

● Overview of South Korean and Korea‑Focused Suppliers

● Korean Specialists in Rubber Track and Undercarriage Parts

● How Global Rubber Track Undercarriage Manufacturers and Suppliers Serve Korea

● Undercarriage Components and System Integration

● Kemer's Position Among Rubber Track Undercarriage Manufacturers and Suppliers

● Key Requirements of Korean OEMs and Dealers

● Typical Applications Using Rubber Track Undercarriages in South Korea

● Technology and Innovation Trends in Korean Crawler Markets

● How Kemer Supports South Korean Customers

● Best Practices for Korean Buyers Selecting Undercarriage Partners

● Ideas for Visual and Multimedia Content

● FAQ

>> 1. What do Rubber Track Undercarriage Manufacturers and Suppliers provide?

>> 2. Why are rubber track undercarriages popular in South Korea?

>> 3. How does Kemer compare to other Rubber Track Undercarriage Manufacturers and Suppliers?

>> 5. Can Rubber Track Undercarriage Manufacturers and Suppliers support autonomous or smart machines?

South Korea has become an attractive destination for sourcing crawler modules from global Rubber Track Undercarriage Manufacturers and Suppliers, driven by a fast‑growing construction and excavator market that relies heavily on tracked machinery. For Kemer and other global Rubber Track Undercarriage Manufacturers and Suppliers, South Korea represents a technology‑intensive, quality‑focused customer base where advanced rubber undercarriage systems can create strong OEM partnerships.

South Korea's construction equipment market is projected to grow steadily, reaching several billion dollars in value by the early 2030s, supported by infrastructure projects, plant investments, and smart city developments. This expansion is boosting demand for crawler excavators, compact track loaders, and other tracked machines, directly increasing the need for high‑quality solutions from Rubber Track Undercarriage Manufacturers and Suppliers.

The excavator segment in South Korea is forecast to grow at a healthy CAGR to 2035, with crawler machines holding a dominant share thanks to their stability and digging performance on varied terrain. As contractors look for lower ground pressure and better flotation on urban and soft ground sites, they increasingly rely on Rubber Track Undercarriage Manufacturers and Suppliers who can deliver durable, low‑noise rubber track systems for demanding job sites.

Rubber Track Undercarriage Manufacturers and Suppliers design complete crawler modules that integrate rubber tracks, track frames, idlers, rollers, sprockets, and final drives into one compact package. These solutions allow South Korean OEMs to shorten development time for mini excavators, aerial platforms, crawler carriers, drilling rigs, and specialty machinery.

Because many Korean projects run machines for long hours on hard ground and mixed surfaces, Rubber Track Undercarriage Manufacturers and Suppliers must combine abrasion‑resistant rubber, reinforced steel cores, and optimized tread patterns to extend track life and reduce downtime for local fleets.

Government‑backed infrastructure investments, highway expansion, port upgrades, and urban redevelopment programs are major factors pushing up construction equipment utilization in South Korea. These projects favor compact, maneuverable tracked machines that can work safely in dense urban neighborhoods with minimal damage to roads and pavements, strengthening the business case for advanced Rubber Track Undercarriage Manufacturers and Suppliers.

In addition, South Korea's strong industrial base and export‑oriented manufacturing create steady demand for locally built excavators and compact machines that are sold into overseas markets. Rubber Track Undercarriage Manufacturers and Suppliers that can meet both domestic and international quality expectations are therefore well positioned to support Korean OEMs as they expand their global reach.

South Korea hosts a mix of domestic component specialists and international undercarriage brands that work together to support local machine builders. Some Korean companies focus on track chains, rollers, and undercarriage parts that feed global Rubber Track Undercarriage Manufacturers and Suppliers and regional dealers. Others act as exclusive distributors for OEM rubber track producers that supply well‑known brands like Caterpillar, John Deere, Bobcat, Volvo, and major Japanese and Korean excavator manufacturers.

For global buyers, this ecosystem means South Korea is not only a strong end market for machines but also a valuable regional hub where Rubber Track Undercarriage Manufacturers and Suppliers cooperate with local partners on technical support, warehousing, and after‑sales service. This combination of domestic know‑how and international technology is one of the reasons South Korea is becoming more visible on the map of global rubber track undercarriage sourcing.

One prominent example is CETEC, which serves as the only official specialty store in Korea for rubber track sales of DRB, a manufacturer supplying rubber tracks as OEM partners to leading global heavy equipment brands. By working closely with DRB and other undercarriage specialists, CETEC can offer advanced crawler solutions that emphasize low vibration, low noise, and improved mechanical coupling performance with construction machinery undercarriage modules.

In parallel, companies such as KTR Undercarriage Parts and other Korean suppliers support the market with a wide range of undercarriage rollers, sprockets, idlers, and chains used on excavators and mini excavators. These components are often supplied to distributors and service companies that cooperate with global Rubber Track Undercarriage Manufacturers and Suppliers to keep Korean fleets running reliably in construction and mining environments.

Many international Rubber Track Undercarriage Manufacturers and Suppliers design modular rubber track undercarriage systems that can be adapted to Korean‑built mini excavators, drilling rigs, crawler dumpers, and aerial platforms. These modules often feature high‑strength engineering rubber tracks, Q345B or similar high‑strength frames, and concealed planetary final drives that can be configured with fixed or variable displacement hydraulic motors.

For Korean OEMs that export worldwide, partnering with experienced Rubber Track Undercarriage Manufacturers and Suppliers ensures compatibility with global standards, making it easier to sell machines into North America, Europe, and other advanced markets that demand robust crawler performance, safety, and emission compliance.

The undercarriage component segment, which includes track rollers, carrier rollers, track chains, and related structural parts, is expected to grow globally along with the expansion of crawler excavators and mini excavators. In South Korea, this trend is visible in rising demand for improved component life and better sealing systems that can withstand tough conditions in construction and quarrying applications.

Rubber Track Undercarriage Manufacturers and Suppliers increasingly work as system integrators, matching undercarriage structures with drives, brakes, and steering controls. For Korean equipment builders, this integration reduces engineering complexity and ensures that rubber track undercarriage modules are delivered as tested, ready‑to‑install systems that meet their machines' performance requirements.

Kemer operates as a specialized manufacturer of crawler undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors, targeting global tracked equipment OEMs. This integrated portfolio allows Kemer to act not only as one of the Rubber Track Undercarriage Manufacturers and Suppliers but also as a complete drive‑train partner that can supply undercarriages and power‑transmission components in a coordinated package.

For South Korean customers, this means Kemer can provide rubber track undercarriage solutions that are pre‑matched with travel drives, swing drives, and hydraulic winches, helping machine builders reduce engineering work and optimize the performance of their tracked platforms in demanding construction and industrial environments. By combining crawler modules with planetary gearboxes, Kemer supports Korean OEMs that need compact, high‑torque solutions for excavators, drilling rigs, and special vehicles.

South Korean OEMs and dealers typically evaluate Rubber Track Undercarriage Manufacturers and Suppliers on several critical criteria, including:

- Consistent rubber quality, with low heat build‑up and cut resistance suitable for heavy urban and infrastructure use.

- Strong metal core design and bonding to prevent de‑tracking and early failures on high‑torque crawler machines.

- Availability of matched undercarriage components, such as sprockets, rollers, idlers, and track frames, that can be integrated quickly into machine designs.

- Local or regional after‑sales support and fast spare‑parts logistics to minimize downtime on job sites.

Rubber Track Undercarriage Manufacturers and Suppliers that can meet these requirements are better positioned to succeed in Korea's competitive and technology‑driven equipment market.

Rubber track undercarriages are widely used on mini and midi excavators working in city centers, suburbs, and industrial zones across South Korea. These machines benefit from low ground pressure, reduced surface damage, and better traction on slopes and soft soils—features that depend directly on the design capabilities of Rubber Track Undercarriage Manufacturers and Suppliers.

In agriculture and landscaping, rubber track undercarriages are increasingly adopted for orchard machines, vineyard equipment, and small tractors operating on delicate soil where compaction must be minimized. The same applies to small crawler carriers and utility machines used for material handling and maintenance in mountainous rural regions, again reinforcing the importance of reliable Rubber Track Undercarriage Manufacturers and Suppliers that understand both industrial and agricultural duty cycles.

South Korea's focus on autonomous and semi‑autonomous construction equipment is pushing undercarriage technology toward lower noise, smoother running, and predictive maintenance features. Rubber Track Undercarriage Manufacturers and Suppliers must therefore design track systems that operate quietly, transmit less vibration to the chassis, and perform reliably with sensor‑laden, telematics‑equipped machines that operate for long hours in tight urban spaces.

Innovation in rubber composition, tread design, and manufacturing processes is also accelerating, with advanced rubber compounds and eco‑friendly materials gaining traction in the Korean market. In parallel, the integration of smart sensors for performance monitoring on undercarriage structures opens the door to predictive maintenance programs that can reduce downtime and improve fleet availability, especially for rental companies and large contractors.

As part of the global community of Rubber Track Undercarriage Manufacturers and Suppliers, Kemer can support South Korean OEMs and distributors in several ways:

- Customized rubber track undercarriage designs tailored to Korean machine dimensions, operating weights, and ground conditions, including compact excavators and specialized carriers.

- Matched travel drives, winch drives, and swing drives configured to Korean hydraulic system standards, helping ensure efficient power transmission and simplified installation for integrators and OEMs.

- Engineering collaboration and remote technical support to help Korean partners optimize crawler layouts, load distribution, and service access, improving machine reliability and life‑cycle cost.

By combining undercarriage structures with drive solutions, Kemer provides South Korean buyers with a one‑stop alternative among Rubber Track Undercarriage Manufacturers and Suppliers and helps OEMs shorten project lead times.

Korean OEMs, rental companies, and dealers choosing partners among global Rubber Track Undercarriage Manufacturers and Suppliers typically follow a structured evaluation process:

- Technical fit: Confirm load ratings, ground pressure calculations, and dimensions match the machine's design envelope and Korean site conditions, including asphalt, rocky soil, and steep slopes.

- Quality systems: Verify certifications, incoming material control, and track bonding processes to ensure consistent performance under long duty cycles and frequent directional changes.

- Lifecycle economics: Compare expected track life, maintenance intervals, and component interchangeability to determine total cost of ownership, not only initial purchase price.

- Collaboration capability: Prefer Rubber Track Undercarriage Manufacturers and Suppliers that can co‑develop customized crawler modules, rather than only offering generic standard sizes and limited engineering support.

Kemer's offering of integrated crawler, gearbox, and hydraulic solutions aligns well with customers that want to simplify supplier management and focus engineering resources on their core vehicle design and machine control systems.

For website content targeting buyers of Rubber Track Undercarriage Manufacturers and Suppliers in South Korea, rich media can help explain technical concepts and build trust:

- A top‑of‑page hero section showing a tracked mini excavator or compact track loader working on a dense urban Korean job site, highlighting the low ground damage benefits of rubber track undercarriages.

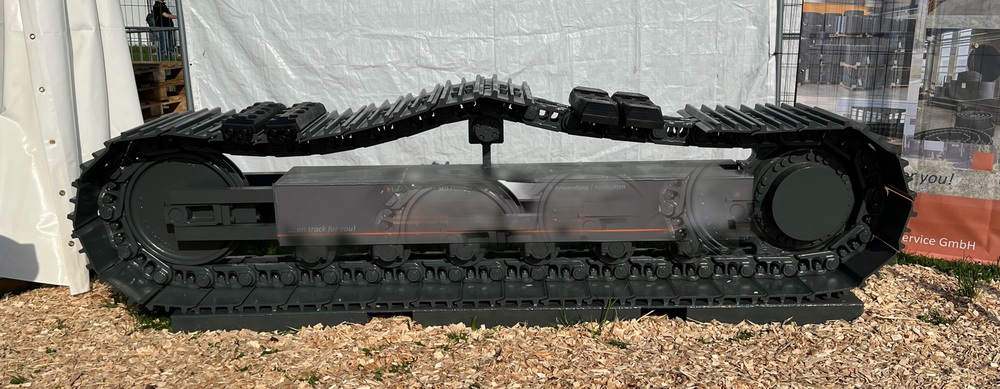

- A schematic diagram illustrating the main elements of a rubber track undercarriage—track, sprocket, rollers, idlers, frame, and travel drive—and showing load paths during operation.

- A cross‑section illustration of advanced rubber tracks used by leading Rubber Track Undercarriage Manufacturers and Suppliers, indicating rubber compound layers, steel cords, and bonding areas that influence durability.

- A short animation explaining how undercarriage components and planetary drives delivered by Kemer work together to move a tracked machine under high torque and variable loads.

- Clips demonstrating before‑and‑after comparisons between worn and new rubber track undercarriages, emphasizing the importance of preventive maintenance when using equipment supplied by Rubber Track Undercarriage Manufacturers and Suppliers.

Such content supports written explanations and helps Korean and international visitors quickly understand the value that Kemer and other Rubber Track Undercarriage Manufacturers and Suppliers bring to modern tracked equipment.

South Korea's expanding construction, infrastructure, and excavator markets create strong, long‑term demand for high‑quality crawler systems, making the country an important destination for global Rubber Track Undercarriage Manufacturers and Suppliers. Korean OEMs and dealers increasingly require rubber track undercarriage solutions that combine durability, low noise, and precise integration with advanced hydraulic and electronic control systems, favoring suppliers that understand both undercarriages and drivetrain technology.

Within this environment, Kemer stands out among Rubber Track Undercarriage Manufacturers and Suppliers by offering complete crawler undercarriage modules along with planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic winches, helping South Korean customers build compact, powerful tracked machines for demanding jobs. For buyers looking to optimize equipment performance and lifecycle cost in South Korea, partnering with integrated solution providers like Kemer offers a compelling path to reliable crawler systems, simplified engineering cooperation, and a stronger competitive position in the regional market served by leading Rubber Track Undercarriage Manufacturers and Suppliers.

Rubber Track Undercarriage Manufacturers and Suppliers design and produce complete crawler modules, including rubber tracks, track frames, rollers, idlers, sprockets, and often integrated travel drives. These systems are delivered as ready‑to‑mount units that OEMs can bolt directly to their machine chassis, reducing development time for equipment such as mini excavators, compact track loaders, and crawler carriers.

Rubber track undercarriages are popular in South Korea because many construction and urban infrastructure projects take place in dense cities where low ground pressure, reduced noise, and minimal pavement damage are critical. As the excavator and compact equipment markets grow, Korean contractors prefer machines supplied by reliable Rubber Track Undercarriage Manufacturers and Suppliers that can handle long duty cycles on asphalt, concrete, and mixed soil conditions.

Kemer differs from many Rubber Track Undercarriage Manufacturers and Suppliers by offering integrated solutions that combine rubber track undercarriages with planetary gearboxes, travel drives, swing drives, and hydraulic winches in a coordinated package. This allows South Korean OEMs to source both the crawler structure and the drivetrain from one partner, simplifying engineering, improving compatibility, and supporting higher machine performance in compact tracked applications.

Korean OEMs should look for proven rubber and steel quality, strong bonding between rubber and core, and track designs tested in similar working conditions, including Korean urban and quarry environments. They should also check whether Rubber Track Undercarriage Manufacturers and Suppliers can customize frame dimensions, integrate selected final drives, support local service, and provide fast spare‑parts logistics within or near South Korea.

Yes, many advanced Rubber Track Undercarriage Manufacturers and Suppliers already support autonomous and smart machines by developing low‑vibration, low‑noise track systems that work well with sensors and telematics hardware used in modern fleets. As South Korea's autonomous construction equipment segment grows, undercarriage suppliers are expected to further optimize rubber compounds, frame designs, and bearing systems to match the needs of highly automated tracked equipment operating on Korean job sites.