Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● Understanding a Planetary Gearbox Before Disassembly

● Typical Construction and Stages Inside a Planetary Gearbox

● Safety Preparations and Lockout/Tagout

● Tools and Work Area Preparation

● External Cleaning and Marking the Gearbox

● Draining Lubricant from the Planetary Gearbox

● Detaching the Planetary Gearbox from the Machine

● Opening the Housing of the Planetary Gearbox

● Removing the Ring Gear and Shims

● Extracting the Planet Carrier Assembly

● Disassembling Planet Gears, Shafts, and Bearings

● Removing the Sun Gear and Output Shaft Components

● Cleaning and Inspecting Planetary Gearbox Components

● Labeling, Storage, and Documentation

● Using Visual References for Disassembly Training

● Applications Where Kemer Planetary Gearbox Solutions Are Used

● Best Practices After Reassembly and Service

● FAQ About Planetary Gearbox Disassembly

>> 1. How often should a planetary gearbox be taken apart?

>> 2. Can a planetary gearbox be disassembled without special tools?

>> 3. What signs show that a planetary gearbox needs to be taken apart?

>> 4. Is it necessary to replace all bearings when a planetary gearbox is opened?

>> 5. Can a planetary gearbox be damaged by incorrect disassembly?

A planetary gearbox can be safely taken apart by following a structured procedure that starts with lockout/tagout, then progresses through draining oil, removing external components, and finally extracting the internal gear stages for inspection and repair. When disassembly is done step by step, the planetary gearbox can be serviced without damaging precision parts such as planet gears, bearings, and seals.[1]

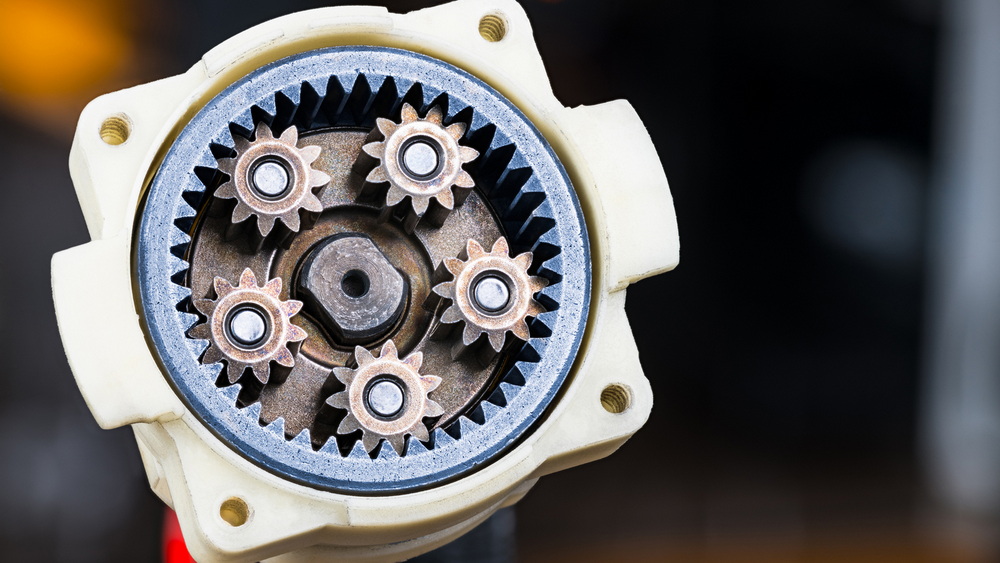

A planetary gearbox is a compact transmission that uses a central sun gear, multiple planet gears, a ring gear, and a planet carrier to transmit high torque in a small package. Before taking apart any planetary gearbox, it is essential to understand how these elements are stacked inside the housing so that they can be removed and later reassembled in the correct order.[1]

- The sun gear normally sits in the center of the planetary gearbox and engages all planet gears equally to distribute load.[2]

- Planet gears rotate around the sun gear and are supported by the planet carrier through shafts and needle bearings inside the planetary gearbox.[2]

- The ring gear forms the outer internal gear and is often integrated with or bolted to the gearbox housing of the planetary gearbox.[2]

- Output torque is typically taken from the carrier or the ring gear, depending on the planetary gearbox design and application.[2]

Most industrial and mobile machinery planetary gearbox designs use one, two, or three stages to achieve the required overall reduction ratio. Each stage repeats the same basic sun–planet–ring layout, but the number of teeth and gear size change to match the desired torque and speed in the planetary gearbox.[2]

- A single-stage planetary gearbox offers moderate ratios and high efficiency with minimal axial length.[2]

- Two- and three-stage planetary gearbox arrangements stack carriers and rings to reach high ratios for heavy-duty drives, such as travel drives and winch drives.[3]

- The carrier of one stage can be connected to the sun gear of the next, allowing compact multi-stage planetary gearbox designs with excellent power density.[4]

Before touching any planetary gearbox connected to a machine, strict safety procedures must be followed to isolate electrical, hydraulic, and mechanical energy sources. Lockout/tagout prevents unexpected movement of shafts or gears that could cause serious injury during disassembly of the planetary gearbox.[1]

- Notify all affected personnel that the planetary gearbox and connected equipment will be shut down and locked out to prevent accidental start-up.[1]

- Shut down the drive motor, hydraulic power pack, or prime mover following the machine manual, then verify that all rotating parts have fully stopped before approaching the planetary gearbox.[1]

- Isolate electrical power at the breaker, block hydraulic supply lines, and bleed any residual pressure before working on the planetary gearbox to avoid oil spray or rotation.[1]

- Attach approved lockout devices and warning tags to each isolated energy source and verify that the machine cannot be started or moved while the planetary gearbox is being serviced.[1]

Preparing the right tools and work area makes disassembly of a planetary gearbox faster, safer, and more reliable. A clean bench prevents contamination of internal components and helps keep the planetary gearbox in good condition during service.[1]

- Common tools include socket sets, torque wrenches, soft-faced hammers, pullers, seal picks, and snap-ring pliers compatible with the planetary gearbox hardware.[1]

- Lifting devices such as hoists or cranes may be required for heavy ring gears, housings, or large planetary gearbox assemblies in tracked machines and winch drives.[3]

- Cleaning materials like lint-free cloths and suitable solvents help remove old oil and dirt from planetary gearbox parts so wear patterns can be seen clearly.[1]

- Marking tools (scribe, paint pen, metal stamps) are used to mark the relative positions of housing, cover, and ring gear before the planetary gearbox is opened.[1]

Before opening a planetary gearbox, cleaning the exterior thoroughly reduces the risk of dirt entering the housing when covers are removed. Dirt or metal chips inside the planetary gearbox can cause rapid wear or scuffing on gear teeth and bearings after reassembly.[1]

- Use a brush or non-aggressive cleaner to remove thick grease, dust, and mud from the outside of the planetary gearbox housing, especially around joints and plugs.[1]

- Clean around filler caps, breather vents, and inspection covers so no debris falls inside when they are opened to access the planetary gearbox interior.[1]

- Scribe or paint a diagonal line across the housing and cover so the planetary gearbox can be reassembled in exactly the same orientation as originally installed.[1]

- If the ring gear is separate from the main case, mark its orientation relative to the mounting face of the planetary gearbox to maintain tooth mesh patterns.[1]

Draining the lubricant is an essential step before opening a planetary gearbox because it reduces mess and allows a clearer view of components once the housing is opened. Used oil can also provide clues about internal wear or damage to gears and bearings in the planetary gearbox.[1]

- Remove the drain plug at the lowest point of the planetary gearbox and allow oil to drain completely into a suitable container of adequate volume.[1]

- Inspect the magnetic drain plug or strainer for metal particles, which may indicate wear on planetary gearbox gear teeth, bearings, or thrust surfaces.[1]

- Note oil colour, smell, and contamination level; dark, burnt, or heavily contaminated oil suggests the planetary gearbox has been running under excessive load or poor cooling.[1]

In many applications, the planetary gearbox is flanged to a hydraulic motor, electric motor, or mechanical input shaft, and also bolted to the driven structure. Detaching the planetary gearbox safely prevents damage to shafts and allows controlled handling during disassembly.[1]

- Support the planetary gearbox with a hoist, crane, or jack before removing mounting bolts so the assembly does not drop or twist unexpectedly.[1]

- Disconnect couplings, motor flanges, and hydraulic lines according to manufacturer procedures, capping open ports to prevent contamination of the planetary gearbox and hydraulic system.

- Remove the mounting bolts and carefully lift the planetary gearbox free from the machine, then transfer it to a clean workbench or service stand for teardown.[1]

With the planetary gearbox on the bench, the next step is to remove the cover and access the internal stages. These parts are often heavy and may require lifting tools to prevent injury or misalignment during disassembly of the planetary gearbox.[1]

- Loosen and remove cover bolts in a criss-cross pattern to release stress evenly from the planetary gearbox housing and avoid distortion.[1]

- Gently separate the cover from the main case using soft prying tools, taking care not to damage gasket surfaces or alignment dowels of the planetary gearbox.[1]

- Lift the cover vertically to avoid scratching the mating faces, and store it on a padded surface away from dirt that could later re-enter the planetary gearbox.[1]

In many designs, the ring gear of the planetary gearbox can be unbolted and removed after the cover is taken off. Correct handling of shims and locating devices preserves the alignment and backlash settings of the planetary gearbox for later reassembly.[1]

- Unbolt the ring gear evenly and lift it out, watching for any shims or locating pins that must remain paired with that specific ring gear and housing.[1]

- Place shims in clearly labeled envelopes or containers and mark them as belonging to that planetary gearbox stage and position.[1]

- Inspect the inner tooth flanks of the ring gear for wear steps, pitting, or fretting, noting any defects that could affect planetary gearbox noise or life.[1]

The planet carrier assembly is the structural core of the planetary gearbox, holding multiple planet gears on shafts and supporting the transmitted torque. Removing the carrier as a complete assembly simplifies access to gears, bearings, and thrust washers for detailed inspection.[1]

- Use lifting lugs or threaded holes on the carrier to attach a hoist, then carefully lift the carrier straight out of the planetary gearbox housing to avoid side loading.[1]

- Keep the carrier level to prevent planet gears or rollers from sliding out of position during removal from the planetary gearbox.[1]

- Place the carrier on a clean, flat surface and note the orientation of each planet position for later reference when reassembling the planetary gearbox.[1]

Once the carrier is out of the planetary gearbox, planet gears can be taken off their shafts so bearings, washers, and spacers can be examined. Careful handling prevents small parts from being mixed between positions, which is important because planet gears in a planetary gearbox are often matched sets.[1]

- Remove locking pins or retaining devices from each planet shaft using the specified punch size recommended for the planetary gearbox.[1]

- Slide each planet shaft out of the carrier, then remove the planet gear, washers, and needle rollers, keeping each set grouped for that location in the planetary gearbox.[1]

- Inspect planet gear bores, needle rollers, and shafts for scoring, spalling, or excessive wear, and record any defects found in the planetary gearbox service notes.[1]

- Repeat the process for all planet positions and for each planetary stage if the planetary gearbox has multiple reduction steps.[1]

The sun gear and output shaft transmit torque through the planetary gearbox and must often be removed for complete overhaul. Accessing these parts may require removing retaining rings, spacers, and bearings from the central axis of the planetary gearbox.[1]

- Remove snap rings or retaining rings that hold the sun gear or shaft bearings in place inside the planetary gearbox case.[1]

- Slide the sun gear off the shaft or out of its bearing support, checking its teeth for pitting, chipping, or deformation that could shorten planetary gearbox life.[1]

- Extract bearings and spacers with appropriate pullers or presses, avoiding impact forces that could crack the planetary gearbox housing or shaft shoulders.[1]

After all major parts of the planetary gearbox are separated, cleaning and inspection determine which components can be reused and which require replacement. Proper inspection helps prevent premature failure after the planetary gearbox is reassembled and returned to service.[1]

- Clean gears, carriers, and housings using recommended solvents, then dry them with lint-free cloths to avoid introducing fibers into the planetary gearbox.[1]

- Examine gear teeth for wear patterns, pitting, cracks, and broken corners, paying special attention to heavily loaded planet gears in the planetary gearbox.[1]

- Check bearings for roughness, noise, and play by rotating them by hand and measuring clearances with feeler gauges or dial indicators.[1]

- Inspect seals and O-rings for hardening, cuts, or deformation, replacing them as standard practice during planetary gearbox overhaul.[1]

As components of a planetary gearbox are removed, they should be clearly labeled and stored in an organized way to support accurate reassembly. Good documentation also helps track wear trends and plan future maintenance for the planetary gearbox.[1]

- Use trays or labeled containers for each planetary stage and each set of planet gears, keeping parts from different positions separate so the planetary gearbox can be rebuilt correctly.[1]

- Record measurements such as backlash, gear tooth condition, bearing clearances, and seal conditions in a service log for the planetary gearbox.[1]

- Note any unusual damage or contamination that might indicate lubrication issues, overloads, or misalignment in the planetary gearbox application.[1]

Visual references make it easier to understand how a planetary gearbox comes apart and how each component looks during disassembly. Watching real teardown sequences helps technicians recognize correct orientation and safe handling of a planetary gearbox.[5]

- Step-by-step teardown recordings demonstrate removal of covers, ring gears, planet carriers, and sun gears, showing the internal layout of a planetary gearbox in real time.[5]

- Slow-motion sequences of bearing and seal removal highlight correct tool placement and pulling direction for sensitive planetary gearbox components.[5]

- Annotated training materials that combine text and moving images can be used in workshops to standardize planetary gearbox service skills among technicians.[5]

Kemer focuses on planetary gearbox solutions used with tracked undercarriages, hydraulic winches, travel drives, swing drives, and hydraulic motors for global customers. This expertise ensures that each planetary gearbox design is optimized for high torque, compact installation, and demanding duty cycles in both mobile and industrial machinery.

- Planetary gearbox units in travel drives transmit torque from hydraulic motors to the sprockets of tracked chassis in construction and mining equipment.

- Winch drives and swing drives use planetary gearbox stages to multiply torque and provide controlled rotation for lifting and slewing operations in cranes and excavators.

- Customized planetary gearbox designs can be adapted to different mounting interfaces, ratios, and load profiles to serve OEMs worldwide with high reliability.

Once a planetary gearbox is reassembled, post-service checks are essential before it is returned to full load. These checks confirm that the planetary gearbox is correctly assembled, lubricated, and free from abnormal noise or vibration.[1]

- Fill the planetary gearbox with the specified lubricant grade and quantity, then run it under light load while monitoring temperature and sound for any unusual changes.[1]

- Inspect for leaks around seals and connections, and re-torque critical bolts after the first run-in period for the planetary gearbox.[1]

- Update maintenance records with the date, work performed, replacement parts, and any recommendations for future service intervals for the planetary gearbox.[1]

Taking apart a planetary gearbox is a methodical process that begins with strict safety precautions and careful external cleaning, then proceeds through staged removal of the housing, ring gear, planet carrier, sun gear, and bearings. With proper tools, labeling, and inspection practices, technicians can disassemble a planetary gearbox, identify worn components, and prepare the unit for reliable reassembly and long-term service in demanding applications such as tracked drives, winch drives, and swing drives.[1]

The disassembly interval for a planetary gearbox depends on operating hours, load, and environment, but many industrial users perform internal inspections during annual overhauls or when vibration, noise, or oil analysis indicate issues. Heavy-duty planetary gearbox applications in dusty or high-load conditions may require more frequent internal checks than lightly loaded units in clean environments.[1]

Basic hand tools are sufficient for small planetary gearbox models, but larger units usually require pullers, hoists, and sometimes presses to remove gears and bearings safely. Using the manufacturer's recommended tools helps prevent damage to precision components and ensures correct reassembly of the planetary gearbox.[1]

Unusual noise, increased vibration, higher operating temperature, oil leaks, and metal particles in the lubricant are common signs that a planetary gearbox should be opened for inspection. Regular monitoring of these indicators allows maintenance teams to schedule disassembly of the planetary gearbox before catastrophic failure occurs.[1]

Not every overhaul requires replacing all bearings, but any bearing in a planetary gearbox that shows roughness, excessive play, or visible damage should be replaced as a set for that location. Many service practices recommend replacing critical bearings and seals as preventive maintenance during a major planetary gearbox disassembly.[1]

Improper disassembly, such as using excessive force, mixing parts between positions, or failing to mark orientation, can cause serious damage and make a planetary gearbox difficult to reassemble correctly. Following documented procedures and keeping components organized protects the precision fit and alignment required for efficient operation of a planetary gearbox.[1]

[1](https://www.perplexity.ai/search/48bbda53-3286-4ba1-8fca-ff8aafa712a1)

[2](https://www.perplexity.ai/search/18b4905f-f420-4fcf-bdea-980d8760b8f1)

[3](https://www.perplexity.ai/search/a8aa7c83-1c89-4a88-9baf-5105e77ae17b)

[4](https://www.perplexity.ai/search/ff8b65c6-4f9a-4a09-95c6-5bcfc820587a)

[5](https://www.perplexity.ai/search/b6ebff9a-f6db-4639-868a-78a41ff7c4e0)