Views: 222 Author: Robert Publish Time: 2026-01-18 Origin: Site

Content Menu

● Overview of Right Angle Gearboxes

● Kemer – Integrated Right Angle & Planetary Drive Solutions

● Taibang / Twirl and Other Servo‑Focused Right Angle Gear Box Manufacturers

● GIGAGER / SAINI – Precision Right Angle Gear Drives

● Red Sun and Other Bevel‑Gear Right Angle Gear Box Manufacturers

● Dongguan Hanrui / Andantex – Industrial Right Angle Gearbox

● Ever‑Power, Aokman and Large‑Catalog Right Angle Gear Box Manufacturers

● Regional Specialists in Suzhou, Hangzhou, and Jiangsu

● KB‑Type Planetary & Hydraulic Transmission Manufacturers

● High‑Precision and Harmonic‑Type Right Angle Gear Box Manufacturers

● Kemer's Position Among Right Angle Gear Box Manufacturers

● How to Select the Right Angle Gear Box Manufacturer in China

● Practical Sourcing Tips for Global Buyers

>> Cooperation with integrated suppliers

● FAQ About Right Angle Gear Box Manufacturers

>> 1. What industries rely most on Right Angle Gear Box Manufacturers in China?

>> 2. How do Chinese right angle planetary gearboxes compare with European products?

>> 3. Why choose an integrated drivetrain supplier like Kemer instead of a standalone gearbox maker?

>> 5. How can buyers verify the reliability of new Right Angle Gear Box Manufacturers?

China has become a major sourcing base for high‑precision, compact transmission components, and Right Angle Gear Box Manufacturers now serve global OEMs in automation, mobile machinery, packaging lines, and special equipment. By choosing the right supplier, buyers can integrate 90‑degree gearboxes with planetary reducers, travel drives, winch drives, and hydraulic motors into one efficient powertrain.

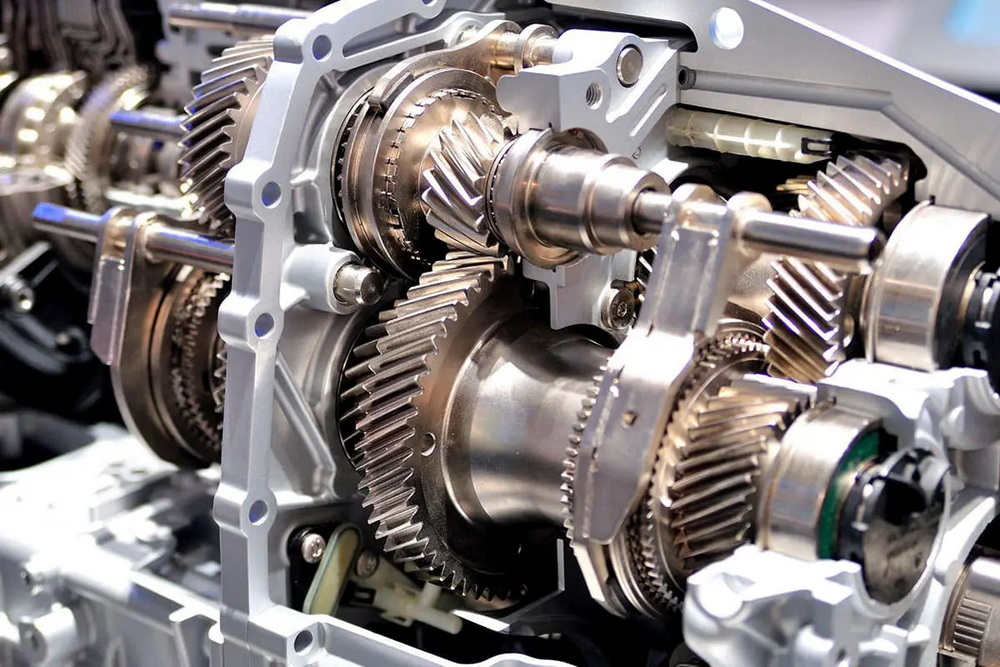

Right angle gearboxes use bevel or hypoid gears to change the power transmission direction by 90 degrees while maintaining torque and efficiency. Many Chinese Right Angle Gear Box Manufacturers combine these units with planetary stages or geared motors to achieve high reduction ratios in a compact envelope.

- Common configurations include spiral bevel, worm‑bevel, T‑shaped right angle, and right angle planetary designs for servo and induction motors.

- Typical applications cover conveyors, rotary tables, cranes, agricultural machinery, tracked equipment, blowers, cooling towers, packaging and food processing machinery.

To help global buyers, the following sections highlight ten representative Right Angle Gear Box Manufacturers in China and outline their strengths and positioning in the market.

Ningbo Kemer Engineering Machinery Co., Ltd. is known internationally for crawler track undercarriages, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors. While Kemer's core catalog focuses on planetary and travel drives, its engineering team can design right angle transmission solutions that integrate with tracked undercarriages and hydraulic winches for construction, concrete pumps, and special vehicles.

- Key strengths

- Deep experience in planetary gearbox reducers, track drives, and winch gearboxes enables complete powertrain packages that can include right angle interfaces where needed.

- Strong customization and R&D capability led by senior hydraulic and transmission specialists helps global OEMs adapt mounting, ratios, and torque ratings to specific machines.

- Typical applications

- Crawler undercarriages from 1 to 60‑ton machines, concrete pump trucks, drilling rigs, and engineering machinery that need compact right angle interfaces between hydraulic motors and planetary gearboxes.

- Winch drives and swing drives where right angle connections help optimize equipment layout while maintaining high output torque and reliability.

Right Angle Gear Box Manufacturers that offer integrated systems similar to Kemer are especially attractive to OEMs seeking fewer interfaces and easier lifecycle management.

Servo‑focused manufacturers such as Twirl Motor and other planetary gearbox specialists supply right angle planetary units designed for servo motor applications. These Right Angle Gear Box Manufacturers address automation, robotics, CNC machinery, and packaging lines where accuracy and low backlash are crucial.

- Key strengths

- Planetary gearheads with high‑performance metal materials and precision machining for medium to high torque applications.

- Right angle planetary gearboxes with motor flanges that match popular servo brands, enabling plug‑and‑play design for motion control systems.

- Typical applications

- Pick‑and‑place robots, gantry systems, indexing tables, and electronic assembly lines.

- Automated packaging and labeling systems that need compact right angle servo axes to save space in cabinets and frames.

These suppliers occupy an important niche among Right Angle Gear Box Manufacturers by combining servo technology with precision, right angle planetary gear stages.

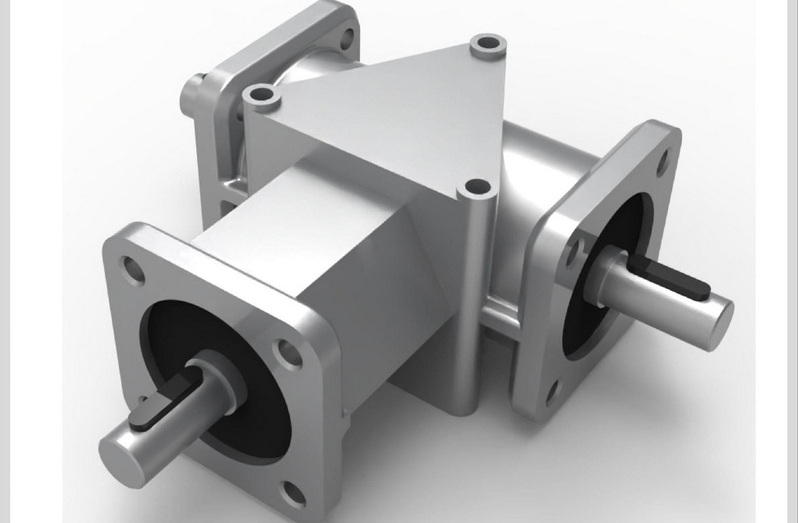

GIGAGER and associated brands in China focus on high‑precision right angle gear drives and rotary actuators for automation and motion control. Their right angle gear drives often feature compact housings, high torsional rigidity, and low backlash suitable for indexing tables and servo axes.

- Key strengths

- Specialization in hollow rotary actuators and right angle gear drives gives high accuracy and repeatability in automation projects.

- Support for multiple mounting options and motor interfaces allows easy matching with international servo and stepper motors.

- Typical applications

- Precision positioning tables, semiconductor handling equipment, and inspection stations that require smooth, low‑backlash right angle motion.

- Compact automation modules where hollow shafts allow cables and media to run through the rotary axis.

As precision‑driven Right Angle Gear Box Manufacturers, these companies focus more on motion control performance than on heavy‑duty torque alone.

Zhejiang Red Sun and similar groups supply 90‑degree bevel gear units for industrial transmissions and agricultural machinery. These right angle bevel gearboxes are frequently used where shafts intersect at a right angle but axial space is limited, such as T‑shaped drives and PTO‑like layouts.

- Key strengths

- Focus on 90‑degree bevel gearboxes and speed reducers with rugged cast‑iron housings, high‑precision spiral bevel sets, and heavy‑load roller bearings.

- Ability to customize gear ratios, shaft types, and housing designs for OEM agricultural and industrial drives.

- Typical applications

- Conveyors, agricultural implements, mixers, and cooling towers requiring high‑speed or high‑torque right angle transmissions.

- Machinery where a T‑shaped right angle gearbox can split power to multiple directions.

These Right Angle Gear Box Manufacturers target robust, general‑industrial applications rather than ultra‑precise servo duties.

Under the Andantex brand, Dongguan Hanrui Automation Technology Co., Ltd. markets industrial right angle gearboxes for automation, machine tools, and conveying systems. These units leverage precision bevel gears and robust housings for medium to high torque applications.

- Key strengths

- Emphasis on seamless operation, low maintenance, and high load‑carrying capacity.

- Design focus on durability and stable performance in automotive, robotics, and machinery applications.

- Typical applications

- Automotive component machining cells, robotics lines, and material handling systems requiring high reliability right angle drives.

- Integration into production lines where right angle outputs improve layout and reduce footprint.

As industrial Right Angle Gear Box Manufacturers, they serve mid‑to‑high‑tier OEM and system integrator customers.

Ever‑Power, Aokman, and other large‑catalog gearbox producers listed on Chinese platforms offer worm, helical‑bevel, and spiral‑bevel right angle gearboxes. These Right Angle Gear Box Manufacturers provide extensive product ranges for general industry.

- Key strengths

- Ability to supply inline, parallel‑shaft, and right angle gearboxes from the same catalog, covering many torque and ratio combinations.

- Focus on competitive pricing, flexible MOQs, and ISO‑based quality systems suitable for distributors and OEMs.

- Typical applications

- Conveyors, mixers, small machinery, and OEM equipment where standard right angle gearboxes are sufficient.

- Replacement and aftermarket markets needing interchangeable right angle gearboxes.

These suppliers are often the first contact point when buyers search broadly for Right Angle Gear Box Manufacturers in China.

Made‑in‑China and similar platforms highlight numerous regional manufacturers and trading‑plus‑factory companies around Suzhou, Hangzhou, Tianjin, Jiangsu, and Zhejiang that supply right angle gearboxes. These Right Angle Gear Box Manufacturers focus on flexible OEM services, moderate volumes, and cost‑effective solutions for mid‑range machinery.

- Key strengths

- Mix of standard catalog products with customized housings, shafts, and mounting faces for specific OEM layouts.

- Proximity to ports, steel suppliers, and machining clusters reduces logistics costs and lead time for overseas buyers.

- Typical applications

- Packaging machines, woodworking equipment, small cranes, and special vehicles requiring right angle power transfer.

- Projects where buyers need rapid engineering feedback and small‑batch customized right angle gearboxes.

These smaller Right Angle Gear Box Manufacturers can be ideal partners for niche or customized projects.

Companies such as Zhejiang New Peka Hydraulic, KB‑type machinery suppliers, and similar firms design planetary reducers, travel drives, swing drives, and winch drives. While they focus on planetary and hydraulic transmissions, many can engineer right angle input or output options for hoist gearboxes, wheel drives, and track drives.

- Key strengths

- Systems thinking across planetary gearboxes, hydraulic motors, and winches enables compact, integrated right angle powertrains for cranes, marine winches, and tracked vehicles.

- Tens of thousands of planetary reducer specifications, with ratio ranges up to 3.3–9000 and high output torque, support a wide range of custom designs.

- Typical applications

- Wheel loaders, excavators, and special vehicles using planetary gearboxes with right angle inputs.

- Marine and offshore winches where right angle stages connect hydraulic motors to drums through planetary reducers.

These manufacturers sit close to Kemer in the value chain of integrated Right Angle Gear Box Manufacturers for heavy equipment.

Some Chinese suppliers of harmonic drives and high‑precision reducers include compact right angle stages designed for robotics and semiconductor equipment. For buyers needing ultra‑low backlash and high positioning accuracy, these Right Angle Gear Box Manufacturers offer niche solutions.

- Key strengths

- Focus on high precision, low noise, and compact size for collaborative robots, inspection equipment, and medical devices.

- Ability to combine harmonic, planetary, and right angle sections in hybrid systems when extremely tight motion control is required.

- Typical applications

- Robot joints and precision axes in electronics and semiconductor manufacturing.

- Equipment where backlash and noise must be minimized while power direction changes by 90 degrees.

Though smaller in volume, these Right Angle Gear Box Manufacturers are vital for high‑end automation projects.

Within the ecosystem of Chinese Right Angle Gear Box Manufacturers, Kemer stands out by combining driveline products—such as crawler undercarriages, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors—into complete motion systems for construction and engineering machinery. Rather than competing only on standalone right angle gearboxes, Kemer focuses on delivering integrated powertrain packages that can include right angle interfaces between hydraulic motors, gearboxes, and tracked or winch outputs.

- Key strengths for global OEMs

- Ability to match right angle transmissions with track undercarriages, winch gearboxes, and swing drives reduces engineering risk and simplifies sourcing.

- ISO‑based quality systems and an annual undercarriage capacity exceeding 100,000 sets indicate strong production capability and reliability.

- Strategic role

- Kemer can act as a system architect among Right Angle Gear Box Manufacturers, taking responsibility for performance at the whole‑machine level rather than just one gearbox.

- This system focus is valuable for OEMs building tracked cranes, drilling rigs, concrete pumps, and special vehicles targeting global markets.

Choosing among many Right Angle Gear Box Manufacturers in China requires a structured evaluation of technical and commercial factors.

- Required torque, speed, duty cycle, and backlash define whether a standard industrial gearbox or precision right angle planetary unit is needed.

- Integration with planetary gearboxes, winch drives, travel drives, or hydraulic motors favors manufacturers like Kemer and KB‑type companies that design entire drivetrains.

- Check capacity, typical lead times, and available stock for popular right angle gearbox models.

- Confirm whether the supplier can support future product upgrades, after‑sales service, and spare parts programs.

Criterion | Typical priority for buyers | Best fit supplier type among Right Angle Gear Box Manufacturers |

Torque & load capacity | Heavy equipment, cranes, tracked machines. | Planetary & hydraulic system makers. |

Backlash & precision | Robotics, CNC, indexing tables. | Precision right angle planetary and harmonic drive makers. |

Cost & lead time | General industrial machinery, conveyors. | Large catalog gearbox manufacturers and regional suppliers. |

System integration ability | OEMs needing full driveline packages. | Kemer-style integrated drivetrain manufacturers. |

Custom engineering support | Special vehicles, marine, mining. | Hydraulic and planetary specialists with R&D teams. |

Working with Chinese Right Angle Gear Box Manufacturers becomes smoother when buyers follow structured sourcing and qualification practices.

- Share detailed data including torque curves, duty cycle, environment, mounting constraints, and interfaces with planetary gearboxes or hydraulic motors.

- Request 3D models, drawings, and performance curves to validate fit with existing designs and standards.

- Check certifications , export experience, and references in similar applications.

- Use sample orders or pilot projects before large‑scale commitments, especially when custom right angle gearboxes are integrated into critical machinery.

- For complex projects, cooperate with integrated Right Angle Gear Box Manufacturers like Kemer that can take responsibility for the whole transmission system.

- Early co‑design involving undercarriages, right angle gearboxes, winch drives, and hydraulic motors helps avoid later redesign and performance issues.

Among the many Right Angle Gear Box Manufacturers in China, buyers can find everything from compact right angle planetary units for servo systems to heavy‑duty bevel gearboxes for cranes, agricultural machinery, and tracked equipment. Kemer distinguishes itself by integrating planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors into coordinated right angle transmission systems for global OEMs seeking complete powertrain solutions.

For long‑term projects, selecting Right Angle Gear Box Manufacturers should go beyond unit price and consider engineering support, system integration capability, quality stability, and after‑sales service. By partnering with experienced drivetrain specialists such as Kemer and carefully evaluating technical requirements, global buyers can build efficient, reliable, and space‑saving machines with right angle gear transmissions at their core.

Right Angle Gear Box Manufacturers in China primarily serve construction machinery, cranes, conveyors, packaging equipment, agricultural machinery, and various automation systems. These sectors value compact, 90‑degree transmission layouts that integrate easily with planetary gearboxes, winch drives, and hydraulic motors.

Many Chinese right angle planetary gearboxes now offer competitive torque density, backlash levels, and life expectancy when produced by established Right Angle Gear Box Manufacturers with ISO‑certified processes. Differences often appear in branding, documentation style, and price level rather than in basic technology, especially for OEM‑oriented products.

An integrated drivetrain supplier such as Kemer can match right angle gearboxes with planetary reducers, travel drives, winch drives, swing drives, and hydraulic motors from one engineering platform. This reduces interface risk, shortens development time, and simplifies after‑sales service compared with sourcing each transmission component from separate Right Angle Gear Box Manufacturers.

Buyers should provide required output torque, speed range, duty cycle, input power type, mounting constraints, environment, and integration details with planetary gearboxes or hydraulic systems. Offering layout drawings and performance expectations helps Chinese Right Angle Gear Box Manufacturers quickly recommend suitable standard models or propose cost‑effective customized designs.

Common methods include reviewing quality certifications, checking export records, assessing engineering responsiveness, and ordering trial units for bench and field testing. Many buyers also visit factories or appoint third‑party inspection agencies to evaluate production, assembly, and testing capabilities before establishing long‑term agreements with Right Angle Gear Box Manufacturers.