Views: 222 Author: Robert Publish Time: 2026-01-17 Origin: Site

Content Menu

● Understanding Hydraulic Winch GPM

● Typical GPM Ranges for Hydraulic Winches

● How to Calculate GPM for a Hydraulic Winch

>> 1. Calculate pump flow from rpm and displacement

>> 2. Estimate motor speed for the hydraulic winch

>> 3. Relate GPM to line speed

>> 4. Check pump and pressure limits

● Key Factors That Determine GPM Needs

>> Winch size and line pull rating

>> Desired line speed and duty cycle

>> Hydraulic power source capacity

>> System type and circuit design

● Practical GPM Examples for Hydraulic Winches

● Matching Your System to a Hydraulic Winch

>> 1. Identify available GPM and pressure

>> 2. Check hydraulic winch specifications

>> 3. Consider cooling, oil volume, and duty cycle

>> 4. Optimize line speed versus control

● Advantages of a Hydraulic Winch at the Right GPM

● Choosing GPM for Different Applications

● FAQ

>> 1. What happens if the GPM is too low for my hydraulic winch?

>> 2. Can I run a higher GPM than the hydraulic winch rating?

>> 3. How do I measure GPM available for a hydraulic winch?

>> 4. Does GPM affect pulling power or only speed on a hydraulic winch?

>> 5. How do I choose the right hydraulic winch GPM for my existing hydraulic system?

A hydraulic winch typically needs between 5 and 25 GPM depending on its size, line pull, and desired line speed, with many 8,000–12,000 lb hydraulic winches operating around 13–18 GPM at 2,000–3,000 psi. Choosing the right GPM for a hydraulic winch is about matching your hydraulic power source to the required pulling force and line speed, not just picking a random flow number.

> Note: In this guide, “GPM” means hydraulic oil flow in gallons per minute supplied to the hydraulic winch motor.

A hydraulic winch converts pressurized oil flow into torque on the drum, so GPM mainly controls how fast the rope moves (line speed), while pressure (psi) controls how much it can pull. Flow determines how quickly the hydraulic winch completes each pull, which is critical for productivity in recovery, construction, and marine applications.

- Flow (GPM) = line speed. Higher GPM makes the hydraulic winch drum spin faster so the rope moves more feet per minute.

- Pressure (psi) = pulling power. Higher pressure allows the hydraulic winch to reach its rated line pull without stalling.

- Power source (PTO, engine-driven pump, or HPU) must be sized to deliver the required GPM and pressure to the hydraulic winch continuously and safely.

Typical industrial and vehicle‑mounted hydraulic winches in the 8,000–15,000 lb range often specify a flow band roughly from 10 to 20 GPM at about 2,000–3,000 psi. This is why matching your hydraulic winch to the existing pump capacity is one of the first checks in any system design.

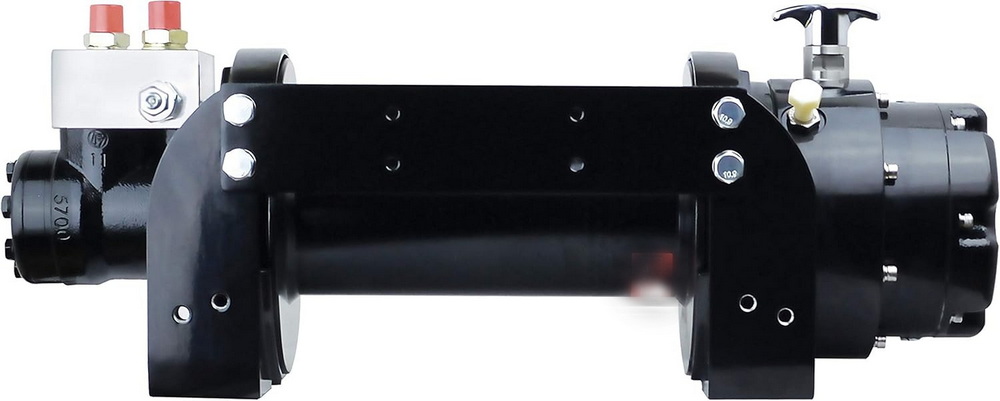

X

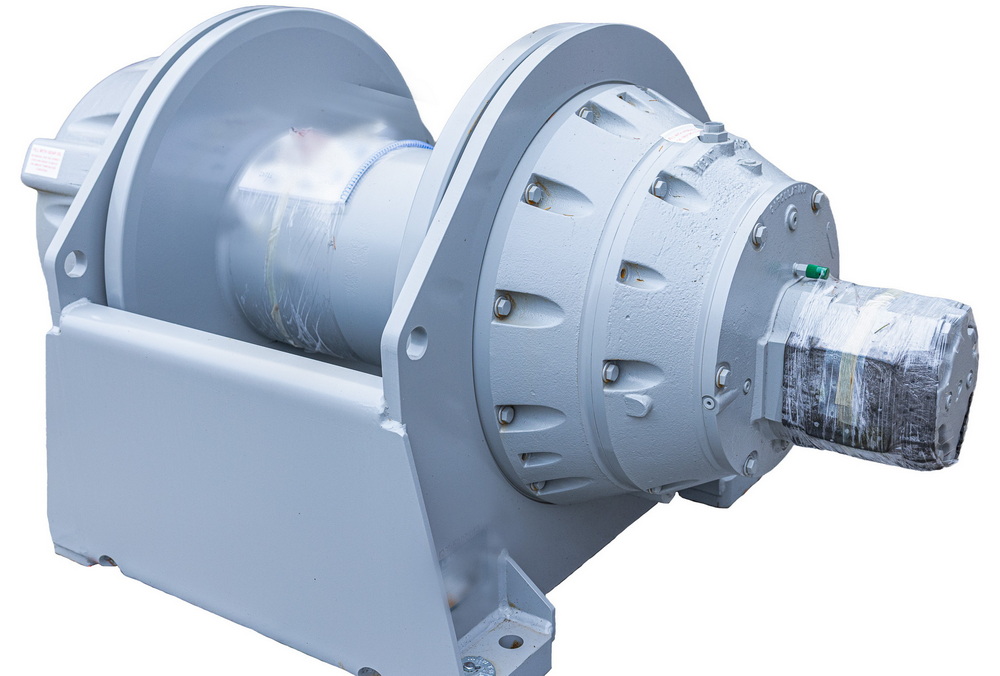

X

Because hydraulic winch designs vary, there is no single “correct” GPM; instead, manufacturers give a recommended operating range. For each hydraulic winch model, you will see a minimum, nominal, and maximum flow rating that defines where the unit works efficiently and safely.

- Light-duty hydraulic winch (e.g., low‑pressure 9,000–12,000 lb): around 3–10 GPM at relatively low pressure can still achieve the rated pull due to efficient gearing and motor sizing.

- Medium industrial hydraulic winch (~10,000 lb planetary): often uses roughly 15–16 GPM to reach its rated line speed and duty cycle.

- Heavy industrial or off‑highway hydraulic winch: can require 18 GPM or more to reach target line speeds at working engine rpm.

Some recovery‑grade hydraulic winches around 30,000 lb capacity use a motor displacement near 9.5 in⊃3;/rev and reach about 16 fpm at roughly 15–16 GPM, illustrating how a modest increase in GPM significantly boosts line speed. Conversely, field examples show that a 9 GPM pump can drive a 20,000 lb hydraulic winch with strong pulling power but only about 4–5 fpm, which is acceptable for occasional heavy pulls but slow for repetitive work.

When the hydraulic winch data sheet is available, the safest method is simply to follow the specified “required oil flow” and “maximum flow” values. If only the hydraulic motor displacement and desired motor speed are known, you can estimate the GPM using standard hydraulic formulas.

Hydraulic pump output flow can be approximated with:

This tells you how much oil your system can actually supply to the hydraulic winch circuit at a given engine or motor speed. It also helps you check whether the pump can support not just the hydraulic winch, but other actuators working in parallel.

In reverse, the same relationship links hydraulic winch motor displacement and flow:

Once motor rpm is known, line speed can be estimated from drum circumference and gear ratio in the hydraulic winch. A larger drum or multiple rope layers will increase line speed at the same motor rpm.

Line speed is commonly given in feet per minute and depends on drum diameter and motor speed. A higher GPM raises the hydraulic winch motor rpm, so the rope travels faster per minute along the drum surface.

- Higher GPM → higher hydraulic winch motor rpm → faster line speed, assuming pressure and power are sufficient.

- Reduced GPM → slower hydraulic winch movement, but pulling force can remain high if pressure capacity is unchanged.

For example, some industrial winch selection guides show that with about 15 GPM, typical line speeds on the working layer fall around 12–18 fpm, depending on drum diameter and gear ratio.

The pump must be rated for at least the relief valve setting in your hydraulic winch system to avoid overload. If your relief valve is set to 2,500 psi and the hydraulic winch requires 18 GPM at this pressure, you need a pump rated for at least 18 GPM at 2,500 psi at the chosen speed.

You also need to confirm that the engine or prime mover has enough horsepower to support that combination of flow and pressure, since hydraulic horsepower is proportional to both. Undersized engines will bog down, reducing both GPM and usable pressure to your hydraulic winch.

Several practical variables influence the GPM a hydraulic winch “needs to be” for safe, efficient operation.

Larger‑capacity hydraulic winches usually require higher pressure to reach their rated pull, but GPM is chosen to give an acceptable line speed at that pressure. A 30,000 lb hydraulic winch working at its top pull will necessarily run more slowly than a 10,000 lb unit at the same GPM, so expectations for speed need to be realistic.

Applications like vehicle recovery, drilling, forestry, and construction might specify a minimum line speed. For example:

- Tow and recovery operators often prefer hydraulic winch line speeds in the 15–30 fpm range under lighter loads to minimize roadside time.

- Lifting or precise positioning tasks might require much slower, more controllable line speeds even if the hydraulic winch can technically run faster at higher GPM.

If existing pump flow is low, the hydraulic winch will still reach high pulling force but at slower speed, which may be acceptable for infrequent use but not for intensive industrial cycles.

Engine horsepower and pump displacement limit how much GPM and pressure can be delivered to the hydraulic winch. Upsizing the hydraulic winch without upgrading the pump may result in insufficient GPM, sluggish performance, or overheating.

On PTO‑driven systems, the hydraulic winch line speed is often calculated at a specific engine rpm (for example, 1,200 rpm). If the PTO speed is 70% of engine speed and the winch needs 18 GPM at that condition, the pump must still be capable of 18 GPM at about 840 rpm. This kind of matching is crucial for correct hydraulic winch sizing.

Many mobile hydraulic winch systems use open‑center circuits where flow is proportional to engine rpm. As engine speed increases, pump GPM rises and the hydraulic winch runs faster, which can be useful but may reduce fine control at high rpm.

Closed‑center or load‑sensing systems can provide more consistent GPM to the hydraulic winch across varying engine speeds, which is helpful on cranes, marine winches, and offshore equipment. In such systems, valve selection and control strategy are as important as GPM itself.

Real‑world data from manufacturers and field experiences help illustrate how different hydraulic winch setups translate into GPM requirements.

- A low‑pressure hydraulic winch around 9,100–12,000 lb can operate using only about 3 GPM at 900–1,400 psi, thanks to an efficient combination of motor displacement and gearing.

- A 10,000 lb planetary hydraulic winch may specify a motor displacement of about 5.9 in⊃3;/rev and require approximately 15.9 GPM at its rated operating point to reach its advertised line speed.

- Some design guides describe hydraulic winches needing 18 GPM to reach the desired line speed at normal PTO rpm, emphasizing the need to size the pump to this flow.

- Operator feedback shows that a 12,000 lb hydraulic winch can be operated at about 6 GPM for controlled, slower pulls, or closer to 12 GPM for faster line speed if the valve and motor are rated for it.

These examples highlight that “What GPM does a hydraulic winch need?” is answered by the specific winch model and the performance expectations of each application, not by a single universal number.

When integrating a hydraulic winch into an existing machine (excavator, truck, skid‑steer, tracked carrier, or marine deck), the process usually follows several steps.

- Measure pump output with a flow meter or rely on the manufacturer's data to find the actual GPM at typical engine rpm.

- Confirm system relief pressure and check whether other functions (boom, travel, auxiliary circuits) will be operating at the same time as the hydraulic winch, which reduces available flow.

Knowing the realistic working GPM, not just the theoretical maximum, is key when choosing a hydraulic winch.

- Look for minimum, nominal, and maximum GPM ratings and safe pressure limits stated by the manufacturer.

- Verify that your actual flow lies inside this window and that you do not exceed maximum rated flow for the hydraulic winch motor, valves, and hoses.

If your pump can deliver more flow than the hydraulic winch allows, a flow‑control or priority valve should be used to protect the winch and maintain controllable speeds.

Continuous heavy use of a hydraulic winch at high GPM can generate significant heat, requiring:

- Adequate reservoir volume to allow oil to de‑aerate and cool.

- An oil‑to‑air or oil‑to‑water cooler sized for the expected hydraulic winch duty cycle.

For intermittent use, such as occasional vehicle recovery, the same hydraulic winch may operate safely with a smaller power pack because the system has time to cool between pulls.

Extremely high GPM can make a hydraulic winch difficult to control at low speeds, especially when inching a load into position.

- Flow‑control valves, pressure‑compensated valves, or proportional valves can be used to tune hydraulic winch speed for different tasks.

- Multiple speed ranges can be created with clever circuit design, such as using a two‑speed motor or parallel/series motor plumbing, allowing both “fast empty” and “slow loaded” modes on the same hydraulic winch.

The best hydraulic winch setup is one that balances raw speed with smooth, predictable control so operators can work safely and efficiently.

A correctly sized hydraulic winch offers several advantages compared to electric solutions, especially in demanding environments:

- Higher continuous duty: A hydraulic winch can run longer at high loads without overheating, as long as the hydraulic system is properly cooled.

- Consistent pulling power: Unlike electric winches that may fade as batteries discharge, a hydraulic winch supplies steady torque as long as the engine and pump maintain flow and pressure.

- Better integration with mobile equipment: A hydraulic winch can share the power source with other hydraulic functions, reducing the need for heavy electrical cabling and large alternators.

When the GPM is matched correctly, the hydraulic winch delivers predictable line speed, strong pulling force, and long service life, making it ideal for tow trucks, construction machinery, offshore platforms, forestry equipment, and specialized tracked carriers.

Because “ideal” GPM varies with how the hydraulic winch is used, it is useful to think in terms of application scenarios.

- Tow and recovery trucks: Often specify 12–18 GPM to their hydraulic winches to achieve line speeds that minimize on‑scene time and improve operator safety on busy roads.

- Construction and piling: May accept slower line speeds if the hydraulic winch is mainly used for precise lifting or tensioning rather than repeated long pulls.

- Marine and offshore: Frequently use multi‑speed or load‑sensing circuits so the hydraulic winch can run fast when lightly loaded and slow but powerful under heavy load.

In each case, the starting point is understanding the pump's GPM and pressure capabilities, then choosing a hydraulic winch designed to perform optimally within those limits.

A hydraulic winch does not have one fixed GPM requirement; instead, each model specifies a recommended flow range that balances line pull, line speed, and system efficiency. For many mobile and industrial units, this means roughly 5–25 GPM, with common 10,000–15,000 lb hydraulic winches often designed around 13–18 GPM at 2,000–3,000 psi. Correctly matching your hydraulic pump capacity, pressure rating, circuit design, and control valves to the hydraulic winch ensures reliable performance, safe operation, and long service life in demanding applications. By carefully considering winch size, desired line speed, duty cycle, and system cooling, you can determine exactly what GPM your hydraulic winch needs to be for your specific machine and job.

Low GPM will make the hydraulic winch run slowly, reducing line speed but not necessarily reducing maximum pulling force if the system can still reach the required pressure. Operators typically see longer cycle times, which may be acceptable for occasional lifts but inefficient for continuous industrial work. In extreme cases, very low GPM can also cause the operator to overspeed the engine to compensate, increasing fuel use and noise without a proportional improvement in performance.

Running a hydraulic winch above its maximum rated GPM can overspeed the motor, increase shock loads, and cause overheating or mechanical damage to seals, bearings, and gears. Exceeding the hydraulic winch flow rating may also void the manufacturer's warranty and create safety risks if loads accelerate unexpectedly. Always stay within the specified flow range and use flow controls if your pump can supply more GPM than the hydraulic winch can safely handle.

GPM can be measured with a flow meter installed in the hydraulic circuit or estimated by timing how long it takes to fill a known volume, such as a one‑gallon container, under normal operating conditions. For example, if it takes 10 seconds to fill one gallon, the pump is supplying about 6 GPM, since 60 seconds divided by 10 seconds per gallon equals 6. This simple field test helps verify that the hydraulic winch is receiving the flow it was sized for, rather than relying only on catalog data.

GPM primarily affects line speed, while system pressure determines the pulling power available from a hydraulic winch at any given moment. However, total hydraulic horsepower is the product of both flow and pressure, so if GPM is too low, the hydraulic winch cannot deliver high pulling force at a reasonable speed, even when pressure is available. In practice, proper GPM ensures that the hydraulic winch can reach its rated load without being painfully slow or causing the system to overheat.

Start by documenting your current pump GPM and system pressure at normal operating rpm, then select a hydraulic winch whose required flow and pressure fall within those limits. Next, evaluate the advertised line speed at that GPM and decide whether it matches your job requirements, considering whether you need fast recovery cycles, precise lifting, or a combination of both. If your pump can deliver more flow than needed, plan to use flow‑control valves or a priority circuit so the hydraulic winch operates at optimal GPM without sacrificing control or safety.

1. https://www.bloommfg.com/blog/post/5-factors-you-need-to-know-about-winches

2. https://winchesinc.com/hydraulic-system-design/

3. https://www.piercearrowinc.com/products/30000-lb-winch-manual-clutch

4. https://www.heavyequipmentforums.com/threads/hydraulic-winch-specs.73733/

5. https://zips.com/blog/how-to-choose-a-winch-sizes-motors-gears

6. https://www.bloommfg.com/blog/post/what-to-look-for-in-a-heavy-duty-winch-a-buyer-s-guide

7. https://www.4wheelparts.com/articles/a-detailed-comparison-of-hydraulic-vs-electric-win

8. https://thern.com/blog/line-speed-questions-answered/

9. https://thern.com/blog/electric-winch-vs-hydraulic/

10. https://www.bloommfg.com/blog/post/5-factors-you-need-to-know-about-winches

11. https://www.triadtechnologies.com/hydraulic-pump-calculations

12. https://www.aberdeendynamics.com/how-to-calculate-gpm-for-a-hydraulic-pump

13. https://www.titanfittings.com/articles/how-to-calculate-gpm-in-a-real-world-hydraulic-circuit

14. https://www.oilburners.net/threads/hydraulic-winch-setup-info-needed.87506/page-2

15. https://www.steelsoldiers.com/threads/gpms-needed-for-m1083-15-000lb-winch.194549/