Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is a Planetary Gearbox Manufacturer?

● Major Global Planetary Gearbox Makers

● Planetary Gearbox for Industrial Applications

● Planetary Gearbox for Precision Motion

● Planetary Gearbox for Mobile Machinery

● Kemer as a Planetary Gearbox Supplier

● Industrial vs Mobile Planetary Gearbox Makers

● How Manufacturers Design a Planetary Gearbox

● How Planetary Gearbox Units Are Manufactured

● Where Planetary Gearbox Makers Sell Their Products

● How to Choose a Planetary Gearbox Manufacturer

● FAQ About Planetary Gearbox Manufacturers

>> FAQ 1. How many companies make planetary gearbox today?

>> FAQ 2. Do all manufacturers design their own planetary gearbox?

>> FAQ 3. What certifications should a planetary gearbox maker have?

>> FAQ 4. Can one manufacturer supply both planetary gearbox and tracked undercarriage?

>> FAQ 5. Why do many winch and swing drives use planetary gearbox?

Ningbo Kemer stands as one of China's largest and most trusted manufacturingenterprises, specializing in the production of track undercarriages, A planetary gearbox is produced by a wide spectrum of global manufacturers, from high‑precision motion control specialists to heavy‑duty industrial and mobile machinery OEM suppliers. These manufacturers design planetary gearbox solutions to deliver compact size, high torque, and high efficiency in tracked undercarriages, winch drives, swing drives, travel drives, and countless other applications.[1][2]

A planetary gearbox manufacturer is a company that focuses on designing, engineering, and producing gear units that use a sun gear, multiple planet gears, and a ring gear to transmit power. Such a manufacturer tailors each planetary gearbox family to specific torque, ratio, precision, and environmental requirements so that the gearbox can be integrated into industrial plants or mobile machines.[3][4]

These manufacturers typically provide:

- Modular planetary gearbox platforms with many ratios, torque ratings, and mounting options.[2]

- Engineering support for customizing shafts, flanges, seals, and lubrication to meet OEM needs for each planetary gearbox.[3]

- Additional components—such as brakes, motors, and sensors—that can be combined into a complete drive built around a planetary gearbox.[2]

Many companies also build dedicated test benches where every planetary gearbox is checked for noise, backlash, leakage, and temperature rise before shipment. This quality focus is essential because a planetary gearbox often works in critical applications where downtime is costly or dangerous.[4][3]

Worldwide, there are many well‑known brands recognized for their planetary gearbox technology and product portfolios. These manufacturers often offer standardized planetary gearbox series alongside tailored designs for special projects.[1][2]

Typical examples include:

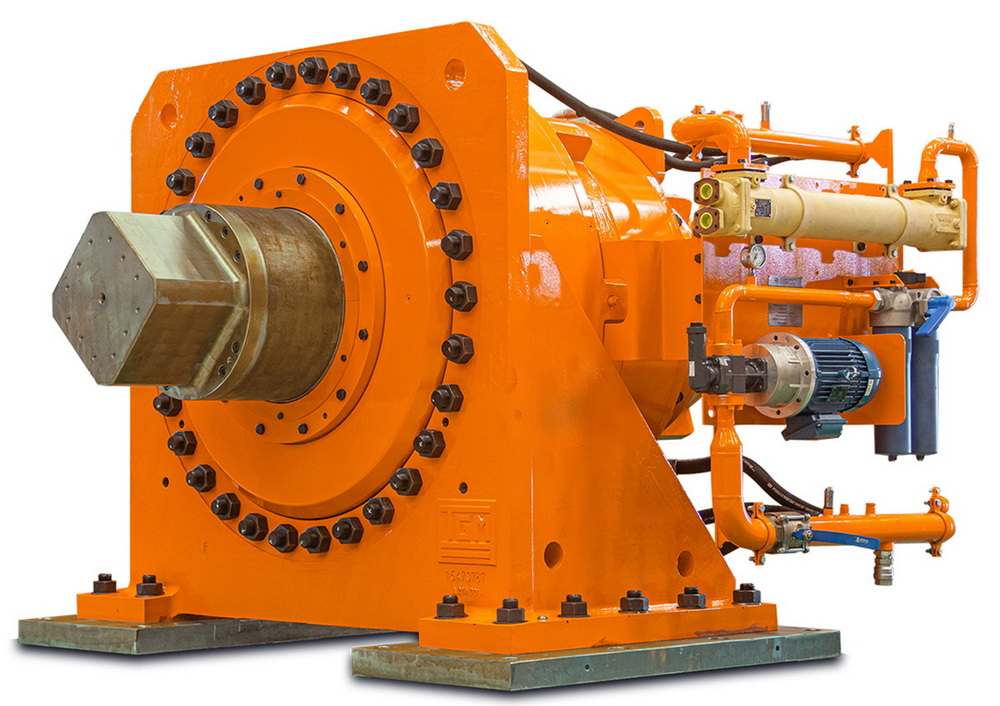

- Industrial drivetrain groups that supply large planetary gearbox units and gearmotors for conveyors, mixers, crushers, winders, and similar heavy equipment.[4][2]

- Precision motion specialists that emphasize low‑backlash planetary gearbox products optimized for servo motors, robotics, CNC machines, and high‑speed automation lines.[5][6]

- Mobile and off‑highway experts that integrate planetary gearbox stages into travel drives, swing drives, and winch drives for construction, mining, and marine machinery.[7][8]

These manufacturers continuously refine their planetary gearbox designs by improving materials, heat treatment, gear geometry, and sealing systems. The goal is to increase torque density and service life while keeping the planetary gearbox compact and easy to mount in tight spaces.[3][4]

In industrial plants, a planetary gearbox is often chosen when equipment needs very high torque and compact dimensions, particularly at low output speeds. By distributing load across multiple planet gears, a planetary gearbox can transmit more torque than many parallel‑shaft designs of similar size.[2][3]

Industrial planetary gearbox units are commonly used in:

- Mixers and agitators, where the planetary gearbox provides slow, powerful rotation for thick or abrasive materials.[2]

- Conveyors, feeders, and bucket elevators that require a planetary gearbox to handle heavy loads and frequent starts and stops.[4]

- Crushers, mills, and winders where shock loads and variable operating conditions demand a robust planetary gearbox solution.[2]

These industrial planetary gearbox systems are usually supplied as complete assemblies with input motors, couplings, and bases. Many manufacturers also offer condition monitoring and connected services so that operators can track planetary gearbox health and schedule proactive maintenance.[4][2]

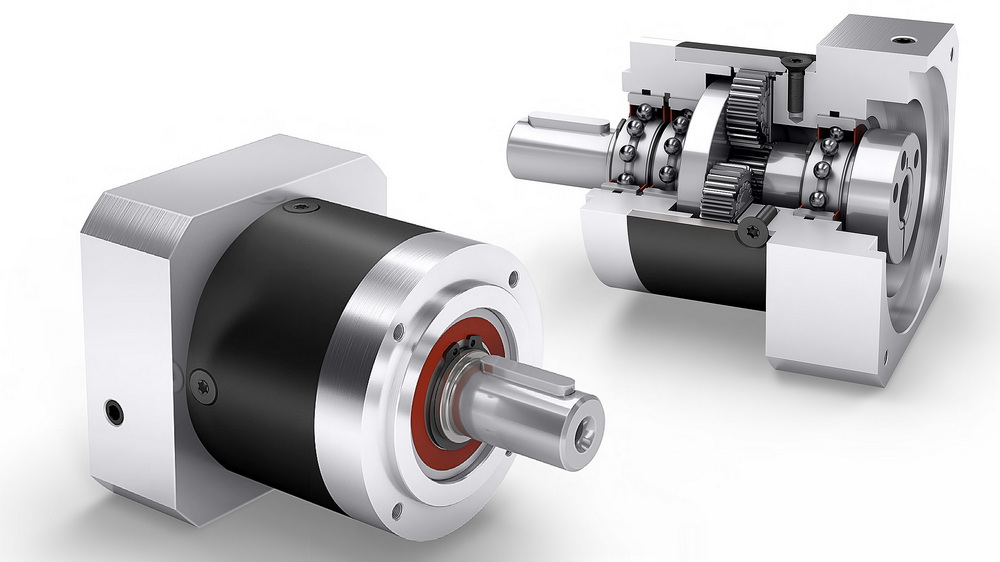

In automation and robotics, a planetary gearbox is often mounted on servo or stepper motors to increase torque and reduce speed while maintaining precise positioning. Precision manufacturers design a planetary gearbox with tight backlash control, optimized tooth profiles, and carefully ground gears to deliver smooth, accurate motion.[6][5]

Key features of precision planetary gearbox products include:

- Very low backlash, allowing the planetary gearbox to transmit motion without noticeable play during direction reversals.[5]

- High torsional stiffness, enabling a planetary gearbox to maintain positioning accuracy in pick‑and‑place systems or CNC axes.[6]

- High efficiency and optimized lubrication so the planetary gearbox can handle high speeds without overheating.[5]

These precision units are commonly offered with standardized motor mounting interfaces, which makes it easy for machine builders to match a servo motor and planetary gearbox as a compact package. Many brands also publish detailed performance curves so designers can select the right planetary gearbox for dynamic and continuous duty cycles.[6][5]

Mobile machinery such as excavators, drilling rigs, crawler cranes, and tracked vehicles relies heavily on planetary gearbox drives because of their compactness and high torque capability. Instead of using a separate gearbox and motor, many mobile solutions use integrated drives where the hydraulic motor and planetary gearbox are built into a single housing.[8][7]

Typical planetary gearbox applications in mobile equipment include:

- Travel drives: a planetary gearbox combined with a hydraulic motor and brake to drive each track or wheel.[7]

- Swing drives: a planetary gearbox unit that rotates an upper structure or crane superstructure with precise control.[8]

- Winch drives: a planetary gearbox mounted inside or next to the winch drum, providing large torque for lifting or pulling loads.[9]

Mobile planetary gearbox makers design their products to withstand shock loads, vibration, contamination, and wide temperature ranges. Many of these planetary gearbox units incorporate integrated parking brakes and fail‑safe features to ensure safe stopping and holding on slopes or during lifting operations.[7][8]

Kemer is a Chinese manufacturer that focuses on tracked undercarriages, hydraulic winches, planetary gearbox units, travel drives, swing drives, and hydraulic motors for global customers. By combining mechanical design with hydraulic know‑how, Kemer supplies planetary gearbox solutions that integrate seamlessly into mobile machinery.[10][11][12]

Kemer's planetary gearbox offerings typically include:

- Track drives that pair a planetary gearbox with a hydraulic motor and support bearings to drive steel or rubber crawlers.[11]

- Winch drives where a planetary gearbox is matched with the drum geometry and motor power to provide safe, controlled lifting.[10]

- Customized planetary gearbox assemblies that can be adapted to different mounting standards and load conditions for OEM equipment.[12]

Because Kemer also produces crawler track frames, idlers, rollers, and other undercarriage components, the company can deliver a complete system solution centered on a planetary gearbox drive. This integrated approach helps OEMs shorten development time and ensure that the planetary gearbox, motor, and undercarriage work together efficiently.[11][10]

Manufacturers of planetary gearbox products can be broadly grouped into industrial, precision, and mobile specialists, each emphasizing different priorities. While the fundamental planetary gearbox concept is the same, the design and options reflect the main applications served by each manufacturer type.[3][4][2]

Type of maker | Typical planetary gearbox focus | Main applications |

Industrial gearbox brands | Heavy duty planetary gearbox and gearmotors with high torque and many ratios. | Steel mills, conveyors, mixers, crushers, winders, and processing lines. |

Precision motion brands | Low backlash planetary gearbox for servo and automation systems. | Robotics, packaging, CNC machines, handling and positioning systems. |

Mobile machinery specialists | Planetary gearbox travel, swing, and winch drives integrated with motors and brakes. | Excavators, cranes, drilling rigs, crawler undercarriages, marine winches. |

Under carriage & winch OEMs | Customized planetary gearbox units matched with track frames and winch drums. | Crawler carriers, concrete pumps, compact track equipment, utility winches. |

Machine builders often cooperate with more than one type of planetary gearbox maker, using industrial units in factories while relying on mobile specialists for off‑highway projects. However, companies like Kemer that combine planetary gearbox units with undercarriages and winches can cover multiple areas with a unified product platform.[10][11][2]

Designing a planetary gearbox starts with defining torque, speed, ratio, duty cycle, and environmental conditions, then translating these into gear geometry and component specifications. Engineers select tooth counts for the sun gear, planet gears, and ring gear so that the planetary gearbox can achieve the desired ratio while maintaining balanced load sharing.[3][4]

Typical steps in designing a planetary gearbox include:

- Calculating gear tooth strength, contact stress, and safety factors based on expected torque and overload conditions.[3]

- Choosing materials and heat treatments that allow the planetary gearbox to resist pitting, scuffing, and wear under long‑term operation.[4]

- Defining bearing arrangements, lubrication paths, and sealing systems to ensure that the planetary gearbox remains reliable in its working environment.[3]

Modern manufacturers use simulation and finite element tools to analyze housing stiffness, gear mesh, and thermal behavior of the planetary gearbox. These tools help optimize the design before prototypes are built and tested on dynamometers or in field trials.[4][3]

Production of a planetary gearbox involves tightly controlled machining, heat treatment, grinding, assembly, and final testing. High precision is necessary because the efficiency and noise behavior of a planetary gearbox depend strongly on gear quality and alignment.[3][4]

Key manufacturing stages for a planetary gearbox include:

- Cutting and grinding of gears and splines, followed by case hardening or nitriding to increase surface hardness and fatigue strength.[4]

- Machining of housings, carriers, and shafts to tight tolerances so that the planetary gearbox maintains correct backlash and bearing preload.[3]

- Assembly of the planetary gearbox with carefully measured components, using jigs and fixtures to keep alignment consistent across production batches.[4]

After assembly, each planetary gearbox or sample from each batch is typically tested for vibration, efficiency, temperature rise, and leakage. Many manufacturers record these results in traceable databases so they can track the quality of every planetary gearbox shipped to customers.[10][3]

Planetary gearbox manufacturers sell through direct OEM contracts, regional distributors, agents, and global online platforms. Their planetary gearbox products reach markets such as construction machinery, industrial automation, renewable energy, material handling, and marine equipment.[13][2]

Common sales channels include:

- Direct project cooperation with large OEMs that need custom planetary gearbox solutions and long‑term supply agreements.[13]

- Partnerships with distributors that keep stocks of standard planetary gearbox units and provide local service and technical support.[3]

- International B2B marketplaces where buyers can browse planetary gearbox catalogs, compare specifications, and place orders.[12][10]

This multi‑channel approach allows planetary gearbox makers to serve both small machine builders and global equipment brands effectively. Companies like Kemer also exhibit at trade shows and industry events to showcase new planetary gearbox models and complete undercarriage systems.[13][10]

Selecting the right manufacturer for a planetary gearbox is crucial for the long‑term performance of any machine or plant. A carefully chosen supplier helps minimize downtime, ensures good after‑sales support, and provides flexibility for future design changes around the planetary gearbox.[4][3]

Important evaluation points include:

- Technical capabilities: torque and ratio range, customization level, calculation support, and experience in similar applications for each planetary gearbox project.[3]

- Quality systems and testing: adherence to standards, documented inspection procedures, and comprehensive testing for each planetary gearbox series.[4]

- Service and logistics: spare parts availability, response time, and delivery options for new planetary gearbox orders and replacements.[13]

For mobile machinery, it is often advantageous to partner with a supplier that can deliver a planetary gearbox already integrated with a motor, brake, and mounting interface. For industrial plants, long‑term availability of the same planetary gearbox series and compatible replacements can be a decisive factor.[7][8][2][4]

Today, planetary gearbox units are manufactured by a diverse group of companies, ranging from precision motion control specialists to heavy‑duty industrial and mobile machinery OEM suppliers. These manufacturers design and produce planetary gearbox solutions that combine high torque, compact size, and high efficiency for applications such as conveyors, mixers, tracked undercarriages, winches, and swing drives.[1][8][2][3]

Manufacturers like Kemer, which integrate planetary gearbox technology with crawler undercarriages, hydraulic winches, travel drives, and hydraulic motors, can provide complete, ready‑to‑install systems for global OEM customers. By understanding different manufacturer types and carefully assessing technical capabilities, quality systems, and service support, machine builders can select the planetary gearbox supplier that best matches their projects.[11][10][3][4]

There are many planetary gearbox manufacturers worldwide, including large international brands and numerous regional specialists serving local markets and niche applications. The exact number changes over time due to new entrants, mergers, and acquisitions in the power transmission industry.[1][13][3]

Not all companies design every planetary gearbox component from scratch; some act as integrators that customize standard units from partner factories. However, leading manufacturers usually maintain core design expertise and testing capability for their main planetary gearbox families.[13][3][4]

Most reputable manufacturers operate under ISO 9001 or similar quality management systems to control the design and production of each planetary gearbox. In heavy industries, additional standards or sector‑specific approvals may be required for planetary gearbox installations in safety‑critical equipment.[10][2][3][4]

Yes, some OEM‑oriented companies specialize in both planetary gearbox drives and complete tracked undercarriage assemblies for construction and engineering machinery. This approach allows them to deliver matched planetary gearbox travel drives and undercarriage frames as integrated solutions for equipment builders.[11][10]

Winch and swing drives frequently employ a planetary gearbox because it offers very high output torque in a compact, coaxial form that fits easily into drums and slewing mechanisms. The multi‑planet configuration of a planetary gearbox shares load between gears, improving shock resistance and durability in dynamic lifting and rotating duties.[8][7]

[1](https://www.twirlmotor.com/top-planetary-gear-motor-manufacturers-in-the-world/)

[2](https://www.bonfiglioli.com/usa/en/product/300m-series_industrial-heavy-duty-geared-products_planetary-geared-units)

[3](https://www.iqsdirectory.com/planetary-gears/planetary-gears-2/)

[4](https://www.zf.com/products/en/industrial_gearboxes/home/industrial_gearboxes.html)

[5](https://www.neugart.com/en-us/)

[6](https://www.apexdynamicsusa.com)

[7](https://shop.dovertwg.com/mechanical/planetary-gear-drives/planetary-gear-drives-with-glide-swing-TWI)

[8](https://en.rrholland.nl/winch-drives/)

[9](https://www.bonfiglioli.com/usa/en/product/fw-series-o-k_winch-drives_winch-drives)

[10](https://nbkemer.en.made-in-china.com)

[11](https://trackundercarriage.goldsupplier.com)

[12](https://china-kemer.en.alibaba.com)

[13](https://ensun.io/search/planetary-gearbox/united-states)