Views: 222 Author: Robert Publish Time: 2026-01-18 Origin: Site

Content Menu

● Why Source From Chinese Winch Machine Manufacturers?

● Top 10 Winch Machine Manufacturers in China

>> 1. Kemer – Integrated Winch and Drivetrain Systems

>> 3. ZHME – Off-Road Electric and Hydraulic Winches

>> 4. Ningbo Chima Winch Co., Ltd.

>> 8. HENAN NYBON MACHINERY CO., LTD.

>> 9. Ningbo Zhonghuang Machine & Electrics Co., Ltd.

>> 10. Regional Hydraulic Winch and Drive Suppliers

● Typical Applications of Winch Machine Manufacturers' Products

● Key Evaluation Factors When Choosing Winch Machine Manufacturers

>> Important technical criteria

>> Quality, certification, and service

● How Kemer Supports Global Winch Machine Projects

● How to Work Effectively With Winch Machine Manufacturers

● FAQ

>> 1. What types of winches do Chinese Winch Machine Manufacturers supply?

>> 2. How can I choose the right Winch Machine Manufacturers for my project?

>> 4. Can Winch Machine Manufacturers provide customized winch and undercarriage systems?

>> 5. What information should I prepare before contacting Winch Machine Manufacturers?

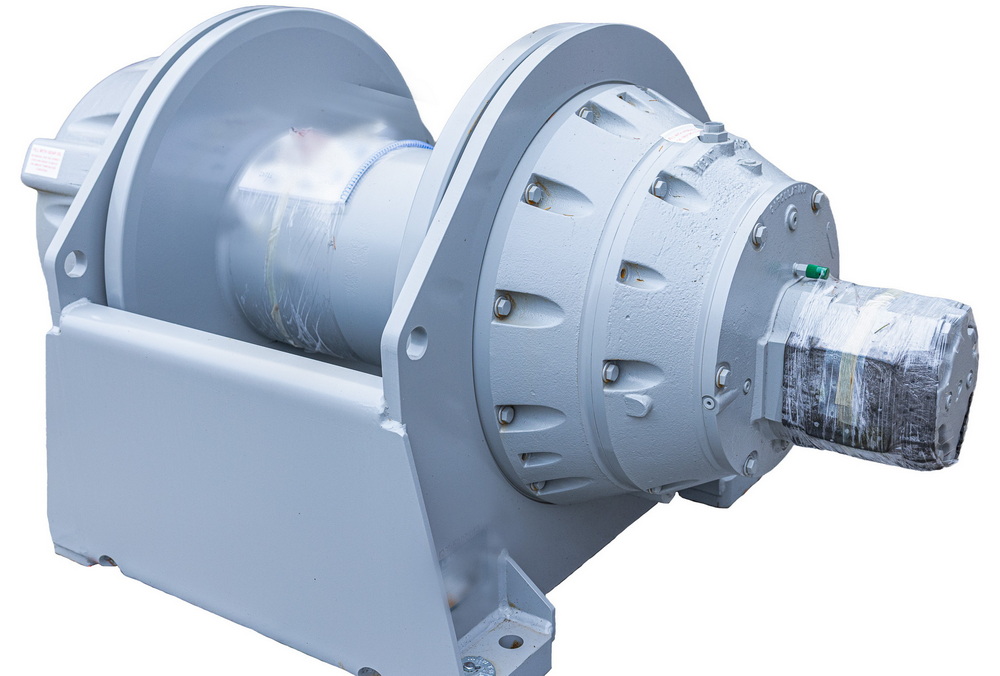

China offers a broad ecosystem of Winch Machine Manufacturers producing electric winches, hydraulic winches, planetary winch drives, marine winches, mining winches, and custom OEM solutions for global markets. Among these Winch Machine Manufacturers, Kemer stands out for combining hydraulic winches with tracked undercarriages, planetary gearboxes, travel drives, swing drives, and hydraulic motors into integrated motion systems.

Chinese Winch Machine Manufacturers have invested heavily in automated production, advanced machining centers, and test benches to deliver industrial winches with reliable pulling capacity and consistent quality. Many Winch Machine Manufacturers in China also hold ISO certifications and provide OEM/ODM services, enabling overseas brands to launch private-label winch products with relatively low engineering risk.

- Competitive pricing due to optimized supply chains, scale, and localized component sourcing.

- Wide product range from small vehicle winches to large industrial and marine winch systems.

- Strong customization support for mounting, drum size, line pull, speed, and control options.

- Experience with international markets in Europe, North America, Australia, and Southeast Asia.

The following are ten representative Winch Machine Manufacturers in China that are active in industrial, construction, marine, and off-road applications. These companies illustrate the diversity of specialized capabilities available to OEMs, distributors, and project buyers who are searching for Winch Machine Manufacturers with reliable engineering and export experience.

Kemer is a professional manufacturer located in Ningbo Economic & Technical Development Zone, focusing on tracked undercarriages, hydraulic winches, planetary gearboxes, travel drives, swing drives, and hydraulic motors. This makes Kemer one of the few Winch Machine Manufacturers able to provide matched winch, gearbox, and undercarriage systems for complete mobile machinery solutions.

- Product scope: hydraulic winches, tracked undercarriages, travel drives, planetary gearboxes, and hydraulic motors.

- Key applications: drilling rigs, piling rigs, construction machinery, crawler equipment, special vehicles, and engineering machines that require compact high-torque drives.

- Strengths: integrated design capability, custom undercarriage parameters, and tailored winch and drive configurations according to working conditions.

Chongpeng Machinery, known via CP Winch Group, is positioned as one of the leading industrial Winch Machine Manufacturers in China, especially in construction and mining sectors. The company has participated in the formulation of winch production standards, supporting OEM requirements for heavy-duty industrial winches.

- Product scope: industrial and construction winches, mining winches, friction winches, sinking winches, spillway winches, piling winches, and customized systems.

- Key applications: mines, metallurgical projects, water conservancy, road and bridge construction, and infrastructure works.

- Strengths: strong engineering support, free design services, and OEM cooperation for global industrial Winch Machine Manufacturers and integrators.

ZHME, headquartered in Ningbo, is a high-tech enterprise that focuses on off-road winches, providing both electric and hydraulic models for ATVs, UTVs, trucks, and competitive off-road vehicles. This manufacturer invests a significant portion of profits into research and development, positioning itself among innovative Winch Machine Manufacturers for off-road applications.

- Product scope: 12V/24V electric winches, off-road winches, ATV/UTV winches, and hydraulic winches for vehicles and competitions.

- Key applications: off-road vehicles, pickup trucks, SUVs, competition vehicles, and utility vehicles requiring reliable self-recovery.

- Strengths: patent portfolio, high production capacity, testing laboratories, and OEM/ODM services for international brands seeking specialized Winch Machine Manufacturers.

Ningbo Chima Winch is a professional winch factory that focuses on multi-functional winches and offers electric, hydraulic, and manual solutions. As one of the established Winch Machine Manufacturers in Ningbo, the company serves ATV, UTV, truck, and industrial users with a comprehensive winch product line.

- Product scope: electric winches, hydraulic winches, hand winches, and winch accessories.

- Key applications: ATV/UTV recovery, off-road 4x4, light trucks, trailers, and small industrial lifting and pulling tasks.

- Strengths: focused expertise on winches, diverse product range, and export experience as a specialized Winch Machine Manufacturer.

Antai Winch is widely recognized as a dedicated winch producer and has been listed as one of the top electric Winch Machine Manufacturers in China in industry overviews. The company offers a broad range of electric winches and also supplies solutions for industrial and vehicle applications.

- Product scope: electric winches for 4x4 vehicles, trailers, and industrial uses, along with related accessories.

- Key applications: vehicle recovery, off-road leisure, workshops, and light construction or lifting tasks.

- Strengths: focus on electric winch technology and service support, making it attractive to distributors seeking specialized Winch Machine Manufacturers.

Runva Winch, founded in 1989 in Jinhua, has developed into a globally active winch producer offering electric, hydraulic, and gasoline winches. As one of the better-known Winch Machine Manufacturers, Runva exports to many countries across multiple industries.

- Product scope: electric winches, hydraulic winches, and gasoline-powered winches covering load ranges from light-duty to heavy-duty.

- Key applications: off-road, industrial lifting, trailers, marine, and special vehicles across global markets.

- Strengths: long operating history, broad product line, international brand presence, and ability to serve as an OEM Winch Machine Manufacturer for various sectors.

TXK is an established Chinese supplier focused on lifting equipment, including wire rope hoists and winches, and is active as a Winch Machine Manufacturer for industrial lifting solutions. Its winches are supported by comprehensive OEM and ODM services for overseas customers.

- Product scope: industrial winches, electric winches, and complementary lifting equipment such as electric hoists.

- Key applications: factories, workshops, small cranes, material handling systems, and light construction sites.

- Strengths: strong background in lifting technology, quality control, and customized solutions as a professional Winch Machine Manufacturer.

Henan Nybon Machinery is known for cranes and lifting equipment and appears in industrial winch supplier listings. While primarily recognized for cranes, it also supplies electric and hydraulic winches for hoisting and pulling tasks, positioning it among multi-product Winch Machine Manufacturers.

- Product scope: electric winches, hydraulic winches, overhead cranes, gantry cranes, and hoists.

- Key applications: workshops, ports, construction sites, factories, and infrastructure projects.

- Strengths: complete lifting systems, engineering capacity, and integrated winch solutions for customers seeking one-stop Winch Machine Manufacturers.

Ningbo Zhonghuang is a manufacturer of electric winches for automotive and ATV applications that also supplies power winches and related products. As one of the Winch Machine Manufacturers in Ningbo, it caters to vehicle recovery and recreational markets.

- Product scope: electric winches for ATVs, autos, and power applications.

- Key applications: ATV recovery, automotive self-recovery, and small trailers.

- Strengths: focused product line, automotive experience, and suitability as an OEM Winch Machine Manufacturer for vehicle accessory brands.

Made-in-China and similar platforms list several Jining- and Shandong-based companies, such as Shandong Daixin Intelligent Technology and Jining Yuansheng, that supply hydraulic winches, reducers, and travel drives. These companies operate as specialized Winch Machine Manufacturers for construction machinery and excavator-based equipment.

- Product scope: hydraulic winches, winch reducers, slewing gearboxes, and final drives for mobile machinery.

- Key applications: excavators, drilling rigs, construction machines, and customized OEM equipment.

- Strengths: synergy between winches, reducers, and drives, appealing to OEMs who need compact integrated solutions from Winch Machine Manufacturers.

Because Chinese Winch Machine Manufacturers cover a wide spectrum of capacities and designs, they can support many industries ranging from light off-road to heavy marine and mining applications. Selecting the ideal Winch Machine Manufacturers depends on the combination of load, duty cycle, working environment, and integration needs.

- Construction and foundation: hydraulic and planetary winches are used on drilling rigs, piling machines, foundation cranes, and tunnel equipment to lift tools, steel, and concrete segments.

- Mining and tunneling: mining winches handle ore hoisting, material transport, shaft sinking, and emergency rescue operations in deep mines.

- Marine and offshore: marine winches cover anchor handling, mooring, towing, and deck operations on ships and offshore platforms.

- Industrial plants: industrial winches move heavy machinery, steel structures, and components within factories and fabrication yards.

- Off-road and recovery: 4x4 and ATV winches support vehicle recovery, forestry, agriculture, and rescue operations in difficult terrain.

When comparing Winch Machine Manufacturers in China, buyers should balance technical performance, reliability, certification, and service responsiveness. The right Winch Machine Manufacturers also need to provide documentation, test reports, and long-term parts support to minimize downtime during the product's life cycle.

- Rated line pull and safety factor suitable for the heaviest expected loads.

- Line speed and drum capacity that match application requirements and duty cycles.

- Type of drive and compatibility with existing power systems.

- Gearbox design and associated efficiency and backlash characteristics.

- Environment: industrial, marine, mining, or off-road conditions, including humidity, salt, dust, and temperature.

- Presence of ISO quality management systems and relevant product certifications .

- Factory testing procedures, including load tests and endurance tests, to validate winch performance.

- Availability of spare parts, clear maintenance instructions, and after-sales support from Winch Machine Manufacturers.

- Transparent documentation including operation manuals, installation guides, and maintenance schedules.

Kemer differentiates itself from many Winch Machine Manufacturers by delivering not only hydraulic winches but also complete undercarriage and transmission packages for tracked machinery. This integration helps OEMs match winch performance with undercarriage traction, gearbox ratios, and hydraulic motor characteristics in a coordinated way.

- Tracked undercarriage customization: Kemer adjusts track width, shoe width, and total length to meet specific terrain and load requirements on crawler equipment.

- Drive and gearbox matching: travel drives, swing drives, and planetary gearboxes are selected to pair optimally with hydraulic winches and hydraulic motors.

- Application engineering: Kemer supports drilling rigs, piling equipment, foundation machinery, and other special engineering machines that require robust Winch Machine Manufacturers with system-level know-how.

To obtain the best results when sourcing from Winch Machine Manufacturers in China, buyers should prepare detailed technical specifications and carefully review supplier capabilities. Clear communication and structured project management help align expectations and reduce development time.

- Define requirements: load, duty cycle, drum capacity, rope diameter, environment, and desired safety factor.

- Verify engineering capacity: ask Winch Machine Manufacturers for drawings, performance curves, and past project references.

- Sample and test: run sample winches under real working conditions before placing large orders.

- Plan life-cycle support: clarify spare parts availability, service response, and documentation before finalizing contracts.

Chinese Winch Machine Manufacturers now provide a comprehensive mix of electric, hydraulic, and planetary winch solutions that serve everything from ATV recovery to deep mining and heavy construction. Kemer offers a distinctive position among these Winch Machine Manufacturers by integrating hydraulic winches with tracked undercarriages, planetary gearboxes, travel drives, swing drives, and hydraulic motors into cohesive systems for demanding mobile machinery. Buyers who carefully evaluate load requirements, duty cycles, quality standards, and service capabilities can build long-term partnerships with Winch Machine Manufacturers in China that deliver both performance and cost advantages.

Chinese Winch Machine Manufacturers supply a wide range of products including electric winches, hydraulic winches, planetary winch drives, marine winches, mining winches, and hand winches for various industries. Many Winch Machine Manufacturers also provide related components such as gearboxes, travel drives, swing drives, and undercarriages to support complete systems.

Choosing the right Winch Machine Manufacturers requires comparing technical capabilities, certifications, application experience, and ability to provide OEM/ODM services. Buyers should review performance data, request samples, and confirm after-sales support to ensure the selected Winch Machine Manufacturers can meet long-term project needs.

Yes, several Winch Machine Manufacturers in China specialize in heavy-duty industrial and mining winches, including friction winches, sinking winches, and construction winches. These Winch Machine Manufacturers invest in robust designs, high-strength materials, and strict testing procedures to support demanding duty cycles in mines, metallurgical projects, and infrastructure works.

Manufacturers such as Kemer can customize both hydraulic winches and tracked undercarriages, adjusting track parameters, drum dimensions, and drive ratios according to specific working conditions. Many other Winch Machine Manufacturers also offer OEM and ODM services, adapting mounting, control systems, and performance characteristics to match customer equipment and branding.

Before contacting Winch Machine Manufacturers, it is important to prepare clear specifications including required line pull, line speed, drum capacity, rope diameter, power source, environment, and duty cycle. Providing these details allows Winch Machine Manufacturers to propose suitable standard models or design customized solutions that minimize engineering time and reduce project risk.

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey