Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Market overview in Azerbaijan

● Why rubber track undercarriages are in demand

● Global trends shaping Rubber Track Undercarriage Manufacturers and Suppliers

● Sourcing channels in Azerbaijan

● Role of Kemer among Rubber Track Undercarriage Manufacturers and Suppliers

● Typical applications in Azerbaijan

● Key selection criteria for Rubber Track Undercarriage Manufacturers and Suppliers

● How visual content supports technical communication

● Advantages of partnering with integrated suppliers like Kemer

● Future opportunities for Rubber Track Undercarriage Manufacturers and Suppliers in Azerbaijan

● FAQ

>> 2. How do rubber track undercarriages benefit construction projects in Azerbaijan?

>> 3. Why are integrated suppliers like Kemer attractive to OEMs in Azerbaijan?

>> 4. Which types of machines in Azerbaijan most often use rubber track undercarriages?

Azerbaijan is rapidly expanding its construction, mining, and agricultural machinery fleets, creating strong demand for reliable Rubber Track Undercarriage Manufacturers and Suppliers that can support local dealers and regional OEMs. For global buyers, understanding how Azerbaijan sources crawler systems from international and regional Rubber Track Undercarriage Manufacturers and Suppliers is essential to building a resilient supply chain.

Azerbaijan's economy is driven by oil and gas, infrastructure projects, and modern agriculture, all of which require compact excavators, tracked loaders, and special equipment running on rubber track undercarriages. These industries increasingly rely on Rubber Track Undercarriage Manufacturers and Suppliers that offer durable tracks, sprockets, rollers, and customized crawler frames suitable for mixed soil and urban job sites.

Local equipment distributors and spare parts companies in Azerbaijan import rubber track undercarriages and components from a wide network of global Rubber Track Undercarriage Manufacturers and Suppliers. Many projects combine imported tracked undercarriage systems with locally assembled superstructures, allowing contractors to optimize cost, lead time, and after‑sales support.

To help buyers, dealers, and OEMs better understand this market, the following sections outline global technology trends, key selection criteria, sourcing channels in Azerbaijan, and the role of integrated suppliers such as Kemer in providing complete crawler solutions.

Rubber track undercarriages significantly reduce ground pressure compared with wheeled solutions, helping machines work on soft soil, wet ground, and landscaped surfaces without severe damage. This makes Rubber Track Undercarriage Manufacturers and Suppliers especially important for city construction, agriculture on delicate soils, and work near existing infrastructure in Azerbaijan.

Rubber track systems also improve traction, stability, and operator comfort by lowering vibration and noise levels. With modern anti‑vibration tread designs, Rubber Track Undercarriage Manufacturers and Suppliers can extend the life of rollers, idlers, and sprockets while keeping machines productive for more hours per day.

From a lifecycle‑cost perspective, many Azerbaijani contractors now prefer rubber track machines for compact excavators, mini dumpers, access platforms, and agricultural harvesters, because they combine fuel efficiency with lower maintenance on prepared or mixed terrain. This shift steadily increases orders placed with global Rubber Track Undercarriage Manufacturers and Suppliers through local dealers.

Worldwide, the rubber track market is growing steadily thanks to construction modernization and agricultural mechanization, with analysts projecting multi‑billion‑dollar demand over the next decade. As a result, leading Rubber Track Undercarriage Manufacturers and Suppliers are investing in new compounds, tread patterns, and undercarriage designs tailored to specific applications.

Key technical trends include:

- Use of high‑strength rubber compounds with embedded steel or synthetic cords to resist cuts, stretching, and de‑tracking during intensive work.

- Advanced tread designs such as block and multi‑bar patterns that balance traction, flotation, and ride comfort for mixed urban and off‑road conditions.

- Anti‑vibration rubber track technologies and optimized undercarriage geometry that protect both the machine and operator while lowering maintenance cost.

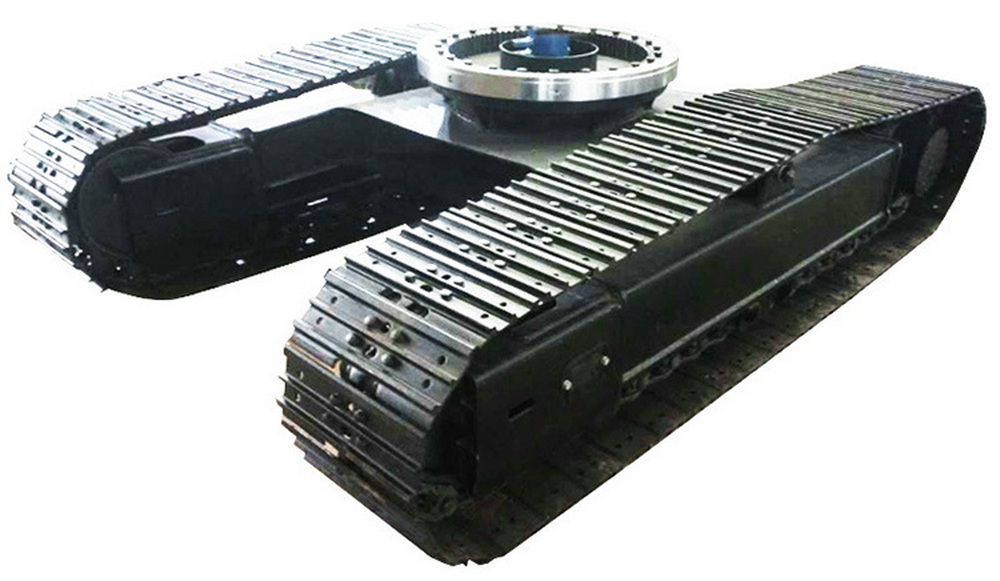

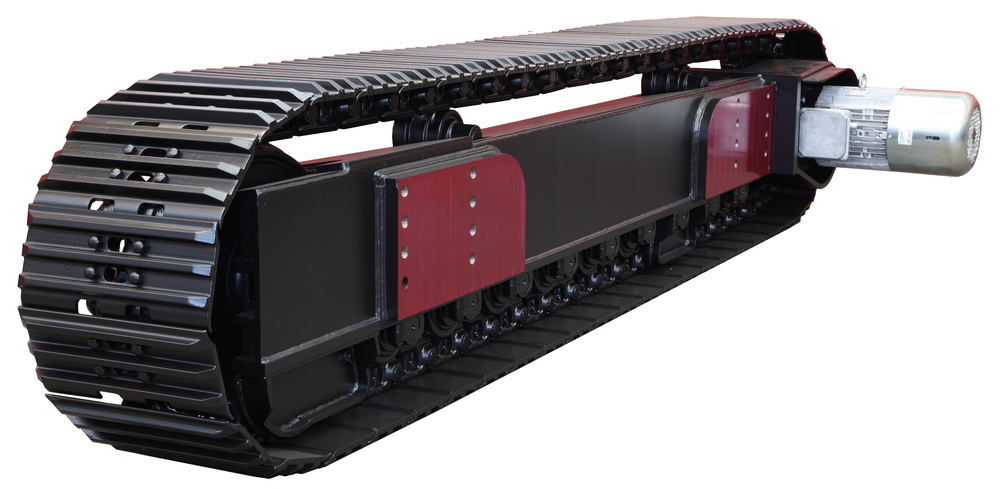

- Integrated rubber track undercarriage modules combining tracks, frames, rollers, idlers, and travel drives, making it easier for OEMs to bolt on complete crawler systems.

These innovations directly benefit Azerbaijani OEMs and dealers who rely on Rubber Track Undercarriage Manufacturers and Suppliers to supply stable, low‑ground‑pressure crawler solutions for demanding job sites.

Azerbaijan does not yet have a large domestic base of Rubber Track Undercarriage Manufacturers and Suppliers, so most rubber track systems are sourced through importers and regional distribution hubs. Local companies specializing in construction and agricultural machinery parts maintain strong links to European and Asian Rubber Track Undercarriage Manufacturers and Suppliers for tracks, chains, rollers, and complete undercarriages.

Typical sourcing channels include:

- Local parts distributors holding inventory of popular rubber tracks and undercarriage components for mini excavators, skid steers, and crawler tractors.

- Direct OEM supply agreements where Azerbaijani machine builders buy complete rubber track undercarriage modules from international Rubber Track Undercarriage Manufacturers and Suppliers such as specialist crawler system producers.

- Project‑based imports for large infrastructure work, where contractors specify certain rubber track undercarriage brands and models when ordering new machinery or replacement parts.

For end users, working with distributors that have established relationships with reputable Rubber Track Undercarriage Manufacturers and Suppliers lowers the risk of counterfeit or low‑quality parts entering the fleet. Reliable sourcing also ensures shorter lead times, predictable pricing, and better technical support.

Kemer is positioned as a specialized supplier of tracked undercarriages and drive solutions, combining rubber track systems with planetary gearboxes, travel drives, winch drives, swing drives, hydraulic winches, and hydraulic motors. This integrated approach allows Kemer to act as one of the most versatile Rubber Track Undercarriage Manufacturers and Suppliers for equipment builders serving Azerbaijan and neighboring markets.

By designing complete rubber track undercarriage modules, Kemer can match the track type, frame design, and hydraulic or planetary drive configuration to the customer's excavator, drilling rig, crawler carrier, or agricultural machine. As a result, OEMs and dealers in Azerbaijan gain a single engineering partner instead of coordinating multiple suppliers for tracks, gearboxes, and motors.

For example, a compact drilling rig destined for pipeline maintenance in Azerbaijan can be equipped with a low‑ground‑pressure rubber track undercarriage, a robust travel drive, and a compact swing drive, all designed and supplied under one project by Kemer. This level of integration is highly attractive to buyers searching for full‑package Rubber Track Undercarriage Manufacturers and Suppliers capable of handling both mechanical and hydraulic aspects of the crawler system.

The demand for Rubber Track Undercarriage Manufacturers and Suppliers in Azerbaijan is closely aligned with the country's main equipment applications. Among the most common uses of rubber track undercarriages are:

- Compact and mini excavators used for city utilities, small foundations, and maintenance work in dense urban districts.

- Skid steer and compact track loaders used for landscaping, road repair, and material handling in confined spaces.

- Crawler transporters, dumpers, and carriers used in pipeline, tunnel, and infrastructure projects where low ground disturbance is required.

- Agricultural harvesters, sprayers, and tractors operating on soft soils and irrigated fields that benefit from reduced soil compaction.

For each of these applications, contractors and OEMs need Rubber Track Undercarriage Manufacturers and Suppliers that can offer correct load capacity, track width, tread pattern, and drive compatibility. Kemer and similar integrated suppliers are well suited to customize undercarriages for these different machine categories.

Buyers in Azerbaijan evaluating Rubber Track Undercarriage Manufacturers and Suppliers typically focus on several critical factors to ensure long‑term performance. Selecting the right partner reduces machine downtime, unplanned maintenance costs, and total cost of ownership.

Important criteria include:

- Load capacity and structural strength: The undercarriage must safely support the machine's operating weight and attachments on the intended terrain.

- Track compound and tread design: Rubber formulation and tread pattern must match the climate and soil conditions found across Azerbaijan's construction and agricultural regions.

- Drive integration: Compatibility with travel drives, hydraulic motors, and gearboxes is essential for reliable performance under heavy loads.

- After‑sales service and spare parts: Strong links between local distributors and Rubber Track Undercarriage Manufacturers and Suppliers ensure quick access to replacement tracks, rollers, and idlers.

- Customization capability: OEMs building specialized equipment look for partners like Kemer that can customize frame dimensions, mounting interfaces, and drive specifications.

By systematically checking these factors, Azerbaijani contractors and OEMs can identify Rubber Track Undercarriage Manufacturers and Suppliers that are able to support long‑term equipment strategies rather than one‑time purchases.

When presenting technical products such as rubber track undercarriages online, visual content plays a significant role in helping buyers understand configuration options, mounting details, and working conditions. High‑quality visuals and embedded videos allow Rubber Track Undercarriage Manufacturers and Suppliers to demonstrate how the track frame, rollers, idlers, sprockets, and drives interact under real operating loads.

For a company like Kemer, publishing detailed visuals of rubber track undercarriages fitted to excavators, carriers, drilling rigs, and agricultural machines makes it easier for Azerbaijani OEMs and dealers to evaluate whether a given design suits their own equipment. Videos showing machines driving over mud, gravel, or asphalt highlight key performance benefits such as traction, stability, and low vibration that text alone cannot convey.

In the context of Azerbaijan, where international buyers often make sourcing decisions remotely, rich visual documentation from Rubber Track Undercarriage Manufacturers and Suppliers significantly reduces technical misunderstandings and accelerates project approval. Demonstration clips can also show how to install, tension, and maintain the rubber track undercarriage, which supports local service teams.

Among global Rubber Track Undercarriage Manufacturers and Suppliers, integrated suppliers that can deliver both undercarriage mechanics and hydraulic drives are particularly valuable to Azerbaijan‑focused OEMs. Kemer's portfolio, combining rubber track undercarriages with planetary gearboxes, travel drives, winch drives, swing drives, hydraulic winches, and hydraulic motors, fits this integrated model.

Key advantages include:

- Shorter development cycles: OEMs can co‑engineer the undercarriage and drive system together, avoiding repeated redesigns between multiple suppliers.

- Optimized power transmission: Matching the rubber track undercarriage geometry with the correct torque and speed from the travel drive improves efficiency and reliability.

- Simplified logistics: Azerbaijan‑bound machines can be shipped with complete crawler modules tested at the factory, reducing assembly work at the final destination.

- Consistent quality: With fewer interfaces between different brands, it becomes easier to guarantee that all parts of the rubber track undercarriage and drive line meet the same quality standard.

Because of these benefits, many contractors and OEMs in emerging markets actively prefer integrated Rubber Track Undercarriage Manufacturers and Suppliers when planning new equipment lines or upgrading existing fleets.

Azerbaijan is expected to continue investing in highways, logistics hubs, urban housing, and modern agricultural projects, all of which require tracked machinery with low ground pressure and high reliability. This long‑term trend will create more opportunities for Rubber Track Undercarriage Manufacturers and Suppliers able to support local distributors with consistent quality and technical expertise.

As environmental and efficiency standards tighten, demand will grow for rubber track undercarriages that minimize soil compaction, reduce noise, and lower fuel consumption, particularly in urban and agricultural applications. Suppliers that can deliver advanced rubber compounds, anti‑vibration technologies, and integrated crawler modules stand to capture a larger share of the Azerbaijani market.

Kemer, with its focus on complete tracked undercarriages, hydraulic winches, planetary gearboxes, travel drives, swing drives, and hydraulic motors, is well positioned to cooperate with local dealers and OEMs as Azerbaijan's fleet of tracked machines continues to grow. By aligning its product roadmap with regional requirements, Kemer can strengthen its status among top Rubber Track Undercarriage Manufacturers and Suppliers serving the Caucasus region.

Rubber track undercarriages have become essential for Azerbaijan's construction, mining, and agricultural machinery, thanks to their low ground pressure, stability, and versatility across mixed terrain. Because the country relies heavily on imports, successful projects depend on reliable Rubber Track Undercarriage Manufacturers and Suppliers working closely with local distributors and OEMs.

Global technology trends, including advanced rubber compounds, optimized tread patterns, and integrated crawler modules, are reshaping how rubber track undercarriages are specified and sourced in Azerbaijan. Integrated suppliers such as Kemer, which combine rubber track undercarriages with planetary gearboxes, hydraulic winches, and travel drives, offer strong advantages for OEMs that need complete crawler systems rather than single components.

For buyers and project managers, selecting Rubber Track Undercarriage Manufacturers and Suppliers with proven engineering capability, strong after‑sales support, and clear communication supported by detailed visuals and videos is the best way to secure long‑term performance in Azerbaijan's demanding operating conditions. As the market grows, those partnerships will play a decisive role in improving machine uptime, efficiency, and total cost of ownership for tracked equipment across the country.

Buyers should evaluate load capacity, rubber compound, tread pattern, and overall structural strength of the undercarriage to ensure it matches the machine and terrain. It is also important to confirm after‑sales support, spare parts availability, and the supplier's experience with similar equipment working in Azerbaijan or comparable environments.

Rubber track undercarriages reduce ground damage on asphalt, pavement, and prepared soil, which is critical for urban construction and road maintenance. They also improve traction and stability on uneven terrain, helping machines work more safely and efficiently on tight or partially finished job sites.

Integrated suppliers can deliver complete crawler solutions, combining rubber track undercarriages with planetary gearboxes, travel drives, hydraulic winches, and motors in one engineered package. This reduces development time, simplifies logistics, and ensures that power transmission and structural design are optimized from the start.

Common machines include compact and mini excavators, compact track loaders, crawler carriers, and specialized agricultural equipment such as harvesters and sprayers. These machines need low ground pressure and high maneuverability to work in urban areas, soft soil, or environmentally sensitive locations.

Manufacturers can provide detailed technical documentation, installation guidelines, and training materials to help local technicians service undercarriage components correctly. They can also share videos that demonstrate tensioning, inspection, and replacement procedures, reducing downtime for equipment owners.

1. https://www.marketsandmarkets.com/Market-Reports/rubber-track-market-236156766.html

2. https://market.us/report/global-rubber-track-market/

3. https://www.transparencymarketresearch.com/excavator-rubber-track-market.html

4. https://www.coherentmarketinsights.com/market-insight/steel-tracks-and-rubber-tracks-market-6099

5. https://www.researchandmarkets.com/reports/6138607/rubber-track-system-market-global-forecast

6. https://www.metastatinsight.com/report/agricultural-rubber-track-market

7. https://introspectivemarketresearch.com/reports/agricultural-rubber-track-market/

8. https://agromach.az

9. https://www.crawlerundercarriage.com

10. https://www.crawlerundercarriage.com/customize/

11. https://www.blsent.com

12. https://www.vematrack.com/en/blog-en/rubber-tracks-vs-steel-tracks/

13. https://www.vtstracksolutions.com/en/crawler-track-undercarriage/rubber-track-crawler-undercarriage/

14. https://www.hinowa.com/en/products/tracked-undercarriages/rubber-tracks