Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Why Malaysia Matters for Rubber Track Undercarriage Manufacturers and Suppliers

● Market Dynamics for Rubber Track Undercarriage Manufacturers and Suppliers

● Typical Applications Served by Rubber Track Undercarriage Manufacturers and Suppliers

● Core Offerings from Rubber Track Undercarriage Manufacturers and Suppliers

● How Kemer Supports Malaysian Rubber Track Undercarriage Demand

● Representative Malaysian Undercarriage and Parts Suppliers

● Advanced Technologies Used by Rubber Track Undercarriage Manufacturers and Suppliers

● Selection Criteria for Malaysian Buyers of Rubber Track Undercarriage Manufacturers and Suppliers

● Advantages of Working with Global Rubber Track Undercarriage Manufacturers and Suppliers

● How Kemer Positions Itself Among Rubber Track Undercarriage Manufacturers and Suppliers

● Future Trends for Rubber Track Undercarriage Manufacturers and Suppliers in Malaysia

● FAQ – Rubber Track Undercarriage Manufacturers and Suppliers in Malaysia

>> 2. How often should rubber track undercarriages be inspected in Malaysian conditions?

>> 3. Can Kemer customize rubber track undercarriages for Malaysian OEM projects?

>> 4. Are rubber track undercarriages suitable for all Malaysian terrains?

Malaysia is becoming an increasingly attractive sourcing hub for Rubber Track Undercarriage Manufacturers and Suppliers as its construction, agriculture, and infrastructure sectors continue to expand and upgrade their tracked equipment fleets. For a global crawler solution provider like Kemer, further strengthening content around Malaysia helps demonstrate deep understanding of how Rubber Track Undercarriage Manufacturers and Suppliers support local OEMs, distributors, and contractors with reliable crawler systems and undercarriage components.

Malaysia's construction equipment industry is projected to grow steadily over the next decade, driven by continuous infrastructure investments in roads, rail networks, industrial parks, and flood‑control projects that rely on tracked excavators and crawler machines. This structural growth directly increases demand for high‑quality solutions from Rubber Track Undercarriage Manufacturers and Suppliers that can ensure machine uptime in demanding tropical environments.

The country also serves as a logistics gateway to Southeast Asia, allowing Rubber Track Undercarriage Manufacturers and Suppliers to use Malaysian distributors as regional hubs to serve nearby markets such as Singapore, Indonesia, Thailand, and Vietnam with undercarriage parts and rubber tracks. By partnering with reliable Malaysian parts houses and importers, global Rubber Track Undercarriage Manufacturers and Suppliers can shorten lead times, reduce freight cost, and react faster to changing fleet requirements.

Global demand for rubber tracks and undercarriage components is forecast to grow at healthy compound annual growth rates, supported by rising mechanization in construction and agriculture and by the shift towards low‑vibration, low‑ground‑pressure tracked platforms. This trend benefits Rubber Track Undercarriage Manufacturers and Suppliers that can deliver advanced rubber compounds, durable track designs, and optimized undercarriage structures for compact and mid‑size equipment.

Asia‑Pacific, including Malaysia, is expected to remain one of the fastest‑growing regions for undercarriage components and rubber track systems thanks to large infrastructure pipelines and expanding plantation agriculture. For global Rubber Track Undercarriage Manufacturers and Suppliers, this means Malaysia is not just a local market but a strategic base within a broader regional growth story.

Across Malaysia, Rubber Track Undercarriage Manufacturers and Suppliers support a diverse fleet of tracked machines operating in construction, plantations, municipal works, and industrial projects. Each application places different loads and duty cycles on rubber track undercarriage systems, requiring careful selection of track width, frame design, and component materials.

Key applications include:

- Mini and medium‑size excavators used on housing projects, utility trenching, and urban redevelopment sites.

- Compact track loaders and skid steer loaders operating in landscaping, building renovation, and warehouse yards where minimal ground damage is required.

- Tracked carriers and dumpers working on palm oil plantations, pipeline corridors, and soft‑soil earthworks.

- Special machines such as drilling rigs, pavers, and access platforms that need stable rubber track undercarriage configurations on mixed or sensitive surfaces.

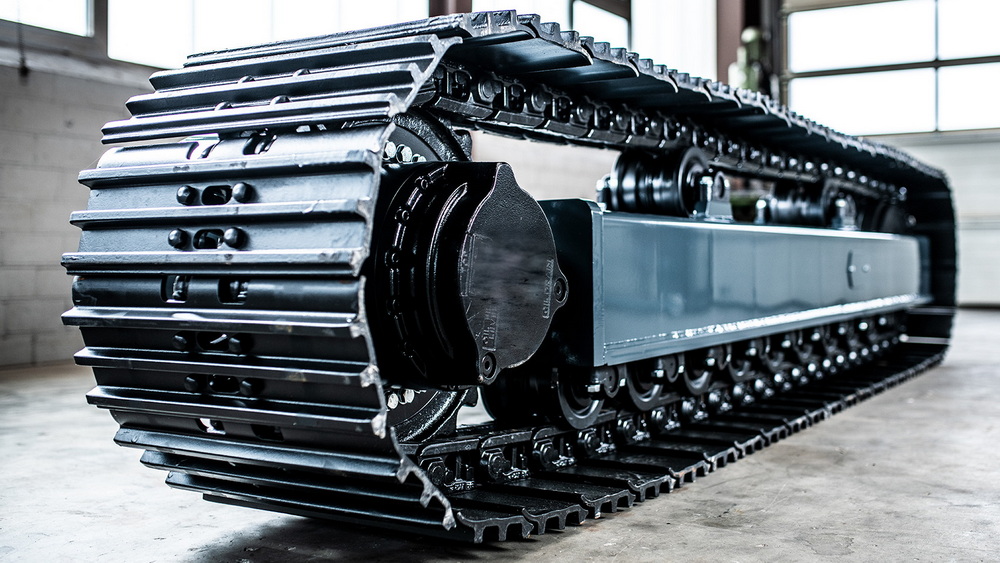

Rubber Track Undercarriage Manufacturers and Suppliers typically provide three primary levels of product offering: individual components, assembled undercarriage modules, and fully engineered track systems integrated with drives. Malaysian buyers can choose the level that best matches their maintenance strategy and project requirements, from simple replacement parts to complete crawler solutions.

Common items supplied by Rubber Track Undercarriage Manufacturers and Suppliers include:

- Rubber tracks and track pads optimized for excavators, compact track loaders, and agricultural machines, using advanced tread designs and reinforced carcasses.

- Undercarriage parts such as track chains, pins and bushings, top and bottom rollers, idlers, sprockets, and shoes or pads for tracked dozers, excavators, and cranes.

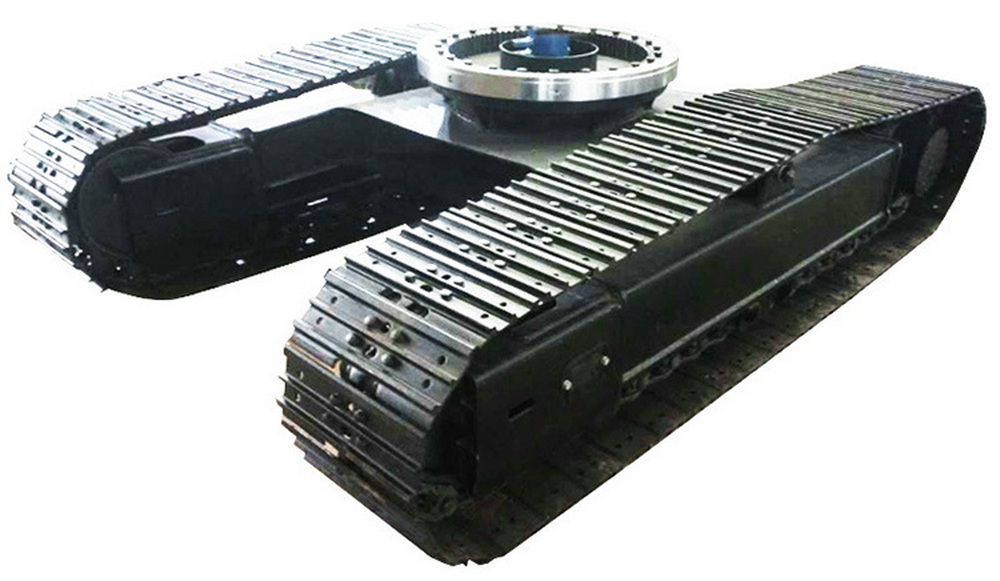

- Complete rubber track undercarriage assemblies featuring welded frames, tensioning mechanisms, rollers, idlers, sprockets, and track systems ready to bolt onto OEM machine frames.

As a specialist in tracked chassis and mechanical‑hydraulic drive solutions, Kemer delivers rubber track undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors tailored to work as a coordinated system. For Malaysian OEMs, distributors, and equipment modifiers, this system‑level capability is valuable because it addresses both the structural undercarriage and the torque, speed, and load requirements of tracked machines.

Kemer can help Malaysian partners in several ways:

- Designing rubber track undercarriage configurations for new machines or conversion projects covering excavators, compact track loaders, crawler carriers, and special equipment.

- Selecting appropriate planetary gearboxes and hydraulic travel motors to match desired travel speeds, tractive effort, and duty cycles under Malaysian operating conditions.

- Supporting winch drives and swing drives used on cranes, drill rigs, and material‑handling equipment that share components with undercarriage and drivetrain solutions.

Several established Malaysian companies supply undercarriage parts, rubber tracks, and related components on behalf of global and regional brands, making them important partners for Rubber Track Undercarriage Manufacturers and Suppliers targeting this market. These companies typically maintain stock in major industrial regions and support a broad range of excavator and dozer models used across the country.

Examples of market players include:

- Heavy machinery parts suppliers in Kuala Lumpur and Selangor that focus on excavator and bulldozer undercarriage components, hydraulic parts, and ground‑engaging tools for major international brands.

- Specialized undercarriage distributors carrying track rollers, idlers, sprockets, track links, and rubber track products, often under their own house brands or as exclusive distributors for international manufacturers.

- Multi‑brand replacement parts companies providing undercarriage parts, sealing products, hydraulic hoses, and engine components to contractors, rental fleets, and plantation operators across Peninsular and East Malaysia.

These partners give Rubber Track Undercarriage Manufacturers and Suppliers on‑the‑ground presence, enabling them to combine global manufacturing strength with localized inventory and support.

Modern Rubber Track Undercarriage Manufacturers and Suppliers invest heavily in materials and design technologies that improve wear life, reliability, and ride comfort of rubber track systems. These innovations are particularly important in Malaysia, where high ambient temperatures, frequent rainfall, and mixed soil conditions can accelerate undercarriage wear.

Key technology areas include:

- Multi‑layer rubber compounds tuned for flexibility, abrasion resistance, cut resistance, and heat dissipation to prevent premature cracking and delamination.

- High‑tensile steel cords and optimized carcass structures that stabilize the rubber track undercarriage, reduce stretching, and maintain proper track geometry over time.

- Tread designs featuring self‑cleaning lugs, directional patterns, and low‑noise profiles to balance traction, ride comfort, and surface protection on paved and unpaved terrain.

To get the best value from Rubber Track Undercarriage Manufacturers and Suppliers, Malaysian OEMs, contractors, and rental companies should evaluate not only purchase price but also performance, service, and long‑term cost. This holistic view helps reduce downtime and extend machine life in a climate where high humidity and heavy rainfall can quickly expose weaknesses in undercarriage design.

Important factors to consider include:

- Technical compatibility with existing machinery, including correct dimensions, mounting points, and load ratings for rubber track undercarriage components.

- Proven field performance and references for similar applications, ideally with data from Southeast Asian or comparable operating environments.

- Availability of local stock, lead times, and after‑sales service through Malaysian partners of Rubber Track Undercarriage Manufacturers and Suppliers.

- Warranty coverage, support for failure analysis, and transparency of quality‑control processes at the manufacturing level.

Collaborating with experienced global Rubber Track Undercarriage Manufacturers and Suppliers allows Malaysian customers to leverage broader R&D, more rigorous testing, and integrated system design capabilities. This can be particularly beneficial for OEMs developing new models or contractors operating mixed fleets that require consistent performance across different machine brands and sizes.

Key advantages include:

- Access to comprehensive rubber track undercarriage product lines covering compact equipment, mid‑size machines, and specialized applications.

- Strong engineering support for tailoring track width, frame configuration, and drive sizing to specific productivity and mobility targets.

- More predictable quality and lifecycle performance, backed by standardized manufacturing and global supply‑chain management.

Within the global network of Rubber Track Undercarriage Manufacturers and Suppliers, Kemer differentiates itself by offering complete tracked chassis solutions alongside drive and motion components. This allows Kemer to work with Malaysian OEMs and integrators at system level, rather than supplying rubber tracks or undercarriage parts in isolation.

For Malaysia‑focused projects, Kemer can:

- Co‑develop rubber track undercarriage systems that match machine weight distribution, ground pressure targets, and stability requirements for local terrains.

- Integrate planetary gearboxes, travel drives, swing drives, and hydraulic motors sized to deliver the desired travel speed, tractive effort, and control characteristics.

- Coordinate with Malaysian undercarriage and parts distributors to ensure replacement components and technical support remain readily available throughout the product lifecycle.

| Priority Area | What Malaysian Buyers Should Look For | Relevance to Rubber Track Undercarriage Manufacturers and Suppliers |

|---|---|---|

| Technical performance | Proven durability of rubber track undercarriage components, correct load ratings, and good traction on clay, laterite, plantation soil, and rock. | Shows whether Rubber Track Undercarriage Manufacturers and Suppliers can meet local jobsite demands and duty cycles. |

| Product range | Availability of rubber tracks, undercarriage parts, and complete crawler modules for key excavator, dozer, and carrier models in Malaysia. | Indicates how easily fleets can standardize on one or two suppliers for most undercarriage needs. |

| Local support | Stock, field service, and warranty handling through established Malaysian distributors and parts centers. | Ensures quick response when rubber track undercarriage repair or replacement is needed. |

| Engineering capability | Ability to customize rubber track undercarriage solutions, integrate drives, and support OEM development projects. | Critical for new machine designs and special‑purpose tracked equipment. |

| Total cost of ownership | Competitive pricing combined with long wear life, reduced downtime, and predictable maintenance intervals. | Determines the real economic value of Rubber Track Undercarriage Manufacturers and Suppliers partnerships over time. |

Malaysian OEMs designing or localizing tracked machinery should involve Rubber Track Undercarriage Manufacturers and Suppliers early in the design process to avoid later rework and performance issues. Early collaboration ensures that mounting interfaces, weight distribution, hydraulic circuit design, and powertrain sizing are aligned with the selected rubber track undercarriage solution.

Recommended best practices include:

- Sharing detailed machine specifications—such as maximum operating weight, duty cycle, gradient capability, and target ground pressure—with shortlisted Rubber Track Undercarriage Manufacturers and Suppliers.

- Building prototypes using pre‑production undercarriage sets and testing them in representative Malaysian conditions, including monsoon seasons and plantation terrain.

- Establishing framework agreements that cover serial production supply, engineering support, and warranty procedures for rubber track undercarriage systems.

For contractors and rental fleets, undercarriage costs often represent one of the largest lifecycle expenses on tracked machines, making the choice of Rubber Track Undercarriage Manufacturers and Suppliers a strategic business decision. By partnering with reliable suppliers and implementing disciplined maintenance, Malaysian operators can significantly reduce downtime and extend the service life of their rubber track undercarriage components.

Practical recommendations:

- Standardize rubber track undercarriage specifications for similar machine classes to simplify inventory management and gain volume purchasing advantages with preferred Rubber Track Undercarriage Manufacturers and Suppliers.

- Implement regular inspection routines to monitor track tension, roller and idler wear, sprocket condition, tread damage, and alignment.

- Track cost per operating hour for each machine or fleet segment to identify which rubber track undercarriage products and suppliers deliver the best long‑term value.

Over the next decade, several macro trends will shape how Rubber Track Undercarriage Manufacturers and Suppliers support the Malaysian market, including increased urbanization, environmental regulations, and the gradual introduction of hybrid and electric tracked machines. These shifts will influence expectations for noise, vibration, ground disturbance, and digital monitoring of rubber track undercarriage condition.

Likely developments include:

- Greater demand for low‑noise, low‑vibration rubber track designs that are compatible with nighttime urban work and sensitive environments.

- Wider use of telematics and sensor‑based monitoring to predict wear on undercarriage components and schedule proactive maintenance, reducing unplanned downtime.

- Collaboration between Rubber Track Undercarriage Manufacturers and Suppliers and OEMs of electrified equipment to handle different torque profiles and acceleration patterns compared with conventional diesel machines.

Malaysia's expanding construction, infrastructure, and agricultural sectors are creating strong and sustained demand for high‑performance solutions from Rubber Track Undercarriage Manufacturers and Suppliers, especially those capable of supporting tropical operating conditions and mixed terrain profiles. By working with experienced global partners such as Kemer, Malaysian OEMs, contractors, and rental fleets can secure engineered rubber track undercarriage systems, planetary gearboxes, and hydraulic drives that improve productivity, extend component life, and optimize total cost of ownership across a wide range of tracked applications.

Malaysian buyers should prioritize technical compatibility, proven field performance in similar climates, and strong local support when evaluating Rubber Track Undercarriage Manufacturers and Suppliers. Looking beyond price to warranty terms, engineering capability, and long‑term cost per operating hour helps ensure that the selected rubber track undercarriage solution delivers sustainable value.

In Malaysia's hot, humid, and often abrasive operating environments, rubber track undercarriages should be inspected regularly, with frequency adjusted based on duty cycle and terrain. Many fleets adopt daily visual checks plus periodic in‑depth inspections focusing on track tension, roller and idler condition, and tread wear to identify issues before they lead to downtime.

Kemer can work closely with Malaysian OEMs to design rubber track undercarriage systems that match machine weight, balance, and performance targets, including special applications such as carriers, drill rigs, or track‑based platforms. By integrating planetary gearboxes, travel drives, swing drives, and hydraulic motors into the same project, Kemer helps ensure that undercarriage, drivetrain, and hydraulic systems are harmonized from the outset.

Rubber track undercarriages are particularly suitable for mixed soils, plantations, urban jobsites, and sensitive surfaces where low ground pressure and reduced surface damage are important. In very sharp rock or heavy mining environments, some applications may still favor steel tracks or hybrid approaches, so consultation with Rubber Track Undercarriage Manufacturers and Suppliers is recommended for extreme duty cycles.

Contractors can reduce total cost of ownership by standardizing undercarriage specifications, partnering with dependable Rubber Track Undercarriage Manufacturers and Suppliers, and following disciplined inspection and maintenance schedules. Tracking cost per hour and comparing performance across different rubber track undercarriage products and suppliers helps identify the combinations that deliver the best long‑term economics for Malaysian fleets.

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey