Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Iran's demand for rubber track undercarriages

● Role of global rubber track undercarriage suppliers in Iran

● Local undercarriage distributors and aftermarket channels in Iran

● Why rubber track undercarriages are growing in popularity

● Export‑oriented undercarriage producers serving Iran

● Typical products from Rubber Track Undercarriage Manufacturers and Suppliers

● Global rubber track undercarriage brands relevant to Iran

● Key selection factors for Iranian buyers

● Technology trends in rubber track undercarriages

● Application segments using rubber track undercarriages in Iran

● Opportunities for OEM cooperation with Iran

● Best practices for sourcing from Rubber Track Undercarriage Manufacturers and Suppliers

● How visuals and application videos support decision‑making

● How Kemer‑type integrated solutions support Iranian customers

● Lifecycle cost and maintenance considerations

● FAQ

>> 1. What are the main benefits of rubber track undercarriages in Iran?

>> 2. How do Iranian buyers usually source rubber track undercarriages?

>> 4. Are rubber tracks replacing steel tracks on machines used in Iran?

>> 5. How fast is the global rubber track market growing and why does it matter for Iran?

Iran is an emerging destination for sourcing crawler systems, with growing demand for compact machines, excavators, agricultural equipment, and special vehicles running on rubber tracks. Global buyers looking at Iran need to understand how local undercarriage distributors combine with international Rubber Track Undercarriage Manufacturers and Suppliers to support this growing market.

Iran's construction, mining, and agricultural sectors are steadily modernizing, which directly increases the use of rubber‑tracked equipment. Infrastructure expansion and mechanized farming create continuous demand for complete undercarriage systems, spare parts, and technical support.

- Construction and mining already represent the largest application segment for rubber tracks globally and this trend is visible across the Middle East.

- Infrastructure projects, oil and gas development, and urbanization drive demand for compact track loaders, mini excavators, and tracked carriers.

For overseas OEMs and dealers, Iran is less about mass production and more about strong local distribution combined with reliable Rubber Track Undercarriage Manufacturers and Suppliers from Asia and Europe.

Many machines working in Iran rely on imported undercarriage components from specialized Rubber Track Undercarriage Manufacturers and Suppliers. These companies deliver complete modular track frames, rubber tracks, and related drive systems that local distributors then integrate or stock as parts.

- Dedicated crawler undercarriage producers offer rubber and steel track assemblies for excavators, aerial platforms, drilling rigs, and special equipment, with load capacities from under 1 ton to well over 30 tons.

- Construction‑focused undercarriage specialists supply rubber tracks, agricultural tracks, rubber pads, and spare parts designed to handle harsh terrain and demanding job‑site conditions.

For Iran, this means many imported “kits” and components from Rubber Track Undercarriage Manufacturers and Suppliers are customized to match local working conditions, soil types, and climate.

While Iran does not yet have many large‑scale branded Rubber Track Undercarriage Manufacturers and Suppliers, it has active distributors handling undercarriage sales, stocking imported tracks, rollers, idlers, sprockets, and related components. These distributors support fleets of excavators, bulldozers, and crawler equipment used in construction, oil and gas, and infrastructure projects.

- Local undercarriage distributors in Tehran and other industrial centers provide a mix of chains, rollers, idlers, sprockets, and complete undercarriage assemblies.

- Major global construction brands operating via Iranian dealers or legacy networks have created a strong installed base of crawler equipment that continuously needs rubber track and undercarriage support.

For international OEMs, partnering with established Iranian parts distributors is often the fastest way to introduce new rubber track undercarriage lines into the country.

Rubber track undercarriages combine low ground pressure with high mobility, making them ideal for urban construction, infrastructure repair, and sensitive soil applications. As Iran's cities expand and more projects happen on finished asphalt, paving, or landscaped areas, the advantages become more obvious.

- Rubber tracks minimize surface damage compared with steel tracks and distribute machine weight more evenly across the ground.

- They offer smoother travel, lower vibration, and reduced noise, which improve operator comfort and allow longer working hours in residential or urban environments.

This growth in rubber track usage in global markets naturally extends into Iran, where contractors and farmers look for equipment that can work year‑round on mixed terrain.

Several export‑focused Rubber Track Undercarriage Manufacturers and Suppliers outside Iran list Iran explicitly or implicitly among their destination markets, supplying both rubber and steel crawler systems. These manufacturers ship complete bolt‑on undercarriage modules, loose rubber tracks, and customized assemblies for special equipment.

- Dedicated crawler undercarriage factories design and manufacture track frames, final drive interfaces, and mounting structures customized around each customer's machine layout.

- Some manufacturers highlight shipments of steel and rubber track undercarriages to multiple overseas markets in Asia, the Middle East, and Europe, demonstrating strong export capability.

This export model lets Iranian buyers access a broad portfolio of Rubber Track Undercarriage Manufacturers and Suppliers without needing domestic large‑scale production.

Whether serving Iran or other markets, leading Rubber Track Undercarriage Manufacturers and Suppliers usually provide a full catalog of crawler components and systems. For Iranian customers, this variety enables both OEM machine building and replacement parts sourcing.

- Complete rubber track undercarriage modules: welded frames, track rollers, idlers, sprockets, tensioners, and rubber tracks, ready to bolt under new machines.

- Standalone rubber tracks for mini excavators, compact track loaders, MEWPs, tracked dumpers, and agricultural carriers, in many widths and pitches.

- Undercarriage accessories such as rubber pads, track shoes, and guarding solutions to protect frames and enhance machine performance.

In the aftermarket, distributors in Iran can select from this global catalog and stock the most common sizes for the local fleet mix.

Several international Rubber Track Undercarriage Manufacturers and Suppliers play an indirect yet important role in the Iranian market by supplying products through regional dealers or export channels. While these brands may not have local factories in Iran, their components often appear on imported machines and in spare‑parts inventories.

Company / Type | Relevance to Iran Market | Key Rubber Undercarriage Offering |

International aftermarket rubber track suppliers | Supply replacement tracks for excavators, mini diggers, and other compact machines used globally, including units operating in Iran via import channels. | Wide size range of rubber tracks for multiple construction and agricultural brands. |

Global undercarriage component manufacturers | Offer rollers, idlers, sprockets, and track chains compatible with popular machine brands operating in Iran. | Undercarriage components and accessories for excavators, dozers, and track loaders. |

Specialized crawler undercarriage designers | Design and produce full rubber and steel track undercarriages for aerial platforms, cranes, drilling rigs, and customized machinery, exporting worldwide including to the Middle East. | Custom rubber track undercarriage systems with engineered load capacity and footprint. |

Construction track system specialists | Provide rubber tracks, rubber pads, agricultural tracks, and undercarriage spare parts for heavy construction and agricultural equipment. | High-value rubber tracks and pads for long-life performance on harsh terrain. |

These categories of Rubber Track Undercarriage Manufacturers and Suppliers help Iranian buyers source both OEM‑grade and aftermarket solutions that fit international machine brands.

When Iranian machine builders, fleet owners, or parts distributors evaluate Rubber Track Undercarriage Manufacturers and Suppliers, several criteria are particularly important. Proper evaluation ensures that each machine receives an undercarriage solution suited to its job profile.

- Load capacity and durability: Underframes and rubber tracks must be engineered for specific machine weights, working hours per year, and expected duty cycles, particularly for mining and construction.

- Terrain and climate matching: Suppliers must recommend tread patterns, rubber compounds, and frame designs suitable for rocky terrain, deserts, agricultural soils, or urban roads.

- Compatibility with hydraulic and mechanical drives: The interface between the rubber track undercarriage and travel motors, gearboxes, and braking systems must be clearly defined.

By focusing on these factors, Iranian buyers can match each tracked machine with an undercarriage solution that balances performance, lifecycle cost, and availability.

Global Rubber Track Undercarriage Manufacturers and Suppliers are investing heavily in material science and design improvements, which ultimately benefit end‑users in markets like Iran. These innovations aim to reduce total cost of ownership while improving safety and operator comfort.

- Advanced rubber compounds and embedded reinforcement wires improve track life, resistance to cuts, and stability at higher travel speeds.

- Optimized tread patterns and carcass design improve traction on mixed terrain, reduce vibration, and minimize soil compaction in agricultural use.

- Modular undercarriage designs allow the same rubber track platform to be adapted across multiple machine types, reducing development time for OEMs.

As these technologies mature, Iranian dealers and OEMs integrating parts from global Rubber Track Undercarriage Manufacturers and Suppliers can market longer warranties and lower maintenance costs.

Rubber track undercarriages are not limited to one type of machine. In Iran, as in other markets, several application segments rely on this technology to enhance mobility and productivity.

- Construction and urban infrastructure: Mini excavators, compact track loaders, and small crawler cranes use rubber track undercarriages to move easily on asphalt and concrete without damaging surfaces.

- Agriculture and horticulture: Tracked harvesters, carriers, and sprayers use rubber tracks to reduce soil compaction and maintain traction on wet or soft ground.

- Special equipment and energy projects: Pipeline machinery, small drilling rigs, and equipment for renewable energy projects often use rubber track undercarriages to access remote or uneven terrain.

Each segment depends on specialized Rubber Track Undercarriage Manufacturers and Suppliers capable of tailoring frame design, footprint, and track pattern to the application.

Iran's combination of domestic engineering capabilities and strong demand for crawler equipment creates opportunities for cooperation between local firms and export‑oriented Rubber Track Undercarriage Manufacturers and Suppliers. These partnerships can focus on both new machine development and the modernization of existing fleets.

- Iranian heavy‑equipment makers already produce crawler excavators and other machines that can integrate imported undercarriage modules and rubber tracks.

- External undercarriage manufacturers with flexible production can quickly customize track frames to match Iranian OEM machine dimensions and mounting points.

- Joint development projects can combine local knowledge of terrain and usage with the global experience of specialized Rubber Track Undercarriage Manufacturers and Suppliers.

Such collaborations help align local product requirements with international undercarriage best practices, improving reliability and export potential.

Whether you are in Iran or serving Iranian customers from abroad, structured sourcing practices help ensure consistent quality and support. Evaluating Rubber Track Undercarriage Manufacturers and Suppliers on technical, commercial, and service criteria is essential.

- Technical alignment: Confirm load ratings, detailed drawings, tolerance standards, and testing methods before placing bulk orders.

- Sample testing: Use pilot batches of rubber track undercarriages on representative machines in Iranian conditions to validate performance before large‑scale adoption.

- Service and logistics: Assess lead times, stock levels, export experience, and warranty policies, especially for long‑distance shipments into Iran.

By following these steps, buyers reduce risk, stabilize supply, and maintain high machine uptime in demanding Iranian applications.

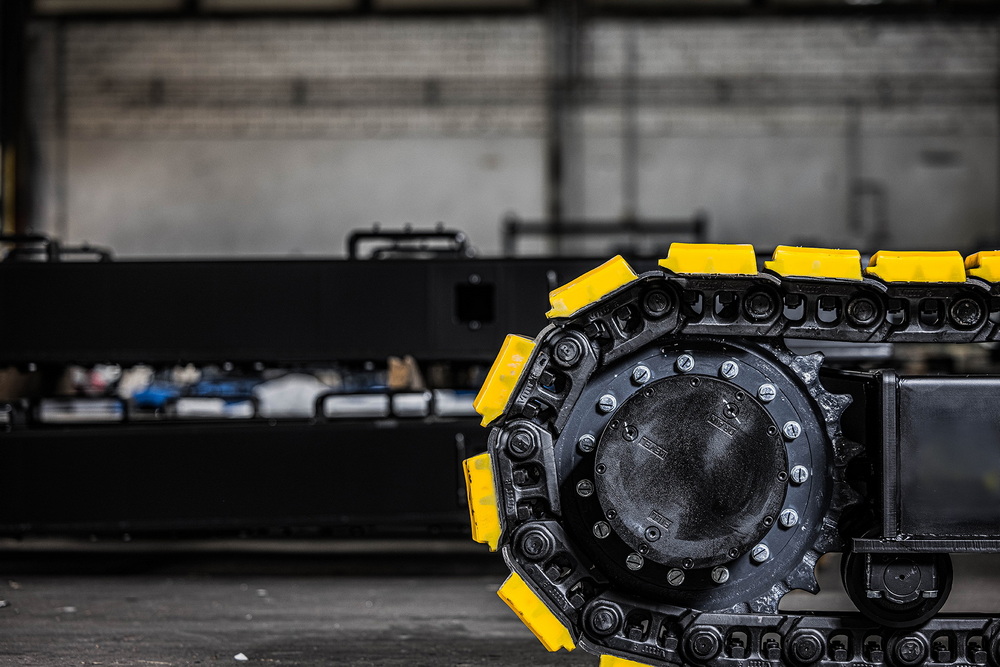

When Iranian engineers evaluate Rubber Track Undercarriage Manufacturers and Suppliers, detailed visuals and application videos are critical for comparing competing solutions. They make it easier to verify frame construction, roller layout, guarding design, and the way tracks behave in real terrain.

In the body of a full website article, consider inserting:

- High‑resolution visuals of rubber track undercarriage assemblies on excavators, drilling rigs, agricultural carriers, and aerial platforms working in Middle Eastern conditions.

- Short videos showing undercarriage movement over rocks, sand, asphalt, and soft soil, highlighting vibration levels, ground disturbance, and track self‑cleaning.

- Explainer clips comparing different tread patterns, rubber compounds, and undercarriage footprints on identical machines.

These visual assets help Iranian customers and overseas buyers quickly understand why certain Rubber Track Undercarriage Manufacturers and Suppliers offer better value for specific use‑cases.

A manufacturer specializing in rubber track chassis, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors can offer integrated solutions that are highly attractive for Iranian OEMs and fleets. Instead of sourcing each component from different vendors, buyers can work with one partner for the entire crawler system.

- Integrated engineering: Matching rubber track undercarriages with travel drives, swing drives, and hydraulic motors ensures smoother motion, better torque delivery, and lower energy loss.

- Simplified interface: With a single engineering team responsible for undercarriage and driveline, installation and commissioning become easier for machine builders in Iran.

- Higher reliability: When the undercarriage and drive system are designed as a single package, loading and dynamic stresses are better understood, reducing failure risk.

For Iranian buyers, working with integrated Rubber Track Undercarriage Manufacturers and Suppliers shortens development time and reduces compatibility issues.

Total cost of ownership is a key factor for Iranian contractors and farmers when choosing Rubber Track Undercarriage Manufacturers and Suppliers. A low purchase price is attractive, but long‑term performance and maintenance cost often matter more.

- Rubber track life: Track quality, reinforcement, and tread design influence how many operating hours can be achieved before replacement.

- Undercarriage wear components: Rollers, idlers, and sprockets must match the rubber tracks to ensure even wear and prevent premature failures.

- Maintenance support: Access to technical documentation, spare parts, and guidance on track tensioning and alignment extends the life of rubber track undercarriages.

By selecting suppliers that provide strong technical support and robust components, Iranian buyers gain better control over lifecycle costs.

Iran's growing construction, mining, and agricultural sectors are steadily increasing demand for high‑quality rubber track crawler systems and replacement parts. Instead of relying only on domestic production, the market is supported by a network of local distributors and powerful global Rubber Track Undercarriage Manufacturers and Suppliers providing complete undercarriage modules, rubber tracks, and spare parts.

By carefully assessing technical specifications, terrain suitability, service capabilities, lifecycle costs, and the advantages of integrated drive and undercarriage systems, Iranian OEMs, fleet owners, and dealers can select Rubber Track Undercarriage Manufacturers and Suppliers that deliver reliable performance and strong return on investment. With the right partners, Iran can leverage modern rubber track technology to accelerate infrastructure development, agricultural productivity, and industrial growth.

Rubber track undercarriages provide lower ground pressure, reduced surface damage, and better traction on mixed terrain compared with steel tracks, which is valuable on Iran's urban projects and agricultural land. They also improve operator comfort by reducing vibration and noise, which helps extend machine working hours and productivity.

Most Iranian buyers rely on local undercarriage distributors that import components and complete track frames from international Rubber Track Undercarriage Manufacturers and Suppliers. These distributors combine imported rubber tracks, rollers, idlers, and sprockets into complete solutions for domestic construction and mining fleets.

OEMs should confirm load capacity, drawing accuracy, and terrain suitability, ensuring that rubber track undercarriages are engineered for local Iranian operating conditions. They should also evaluate supplier lead times, export experience to the Middle East, and warranty or after‑sales policies for long‑distance support.

Rubber tracks are not fully replacing steel tracks, but they are increasingly used on compact track loaders, mini excavators, and specialized carriers where low ground disturbance and high mobility are essential. Heavy dozers and large mining machines in Iran still typically rely on steel tracks, while rubber tracks dominate applications near paved surfaces and sensitive soils.

Global rubber track market value is projected to grow steadily over the coming years, driven by construction and agricultural mechanization worldwide. This growth brings more investment into research and development by Rubber Track Undercarriage Manufacturers and Suppliers, which gives Iranian customers access to longer‑lasting, more efficient crawler solutions and more competitive pricing.

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey