Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Why Thailand Needs Reliable Rubber Track Undercarriage Manufacturers and Suppliers

● Thailand's Construction and Agricultural Equipment Market Overview

● Key Equipment Using Rubber Track Undercarriage Systems in Thailand

● Types of Rubber Track Undercarriage Manufacturers and Suppliers Serving Thailand

● Representative Undercarriage Parts Suppliers in Thailand

● How Global Rubber Track Undercarriage Manufacturers and Suppliers Support Thailand

● Technological Advancements in Rubber Track Undercarriage Systems

● Benefits of Working with Professional Rubber Track Undercarriage Manufacturers and Suppliers

● Typical Products Supplied by Rubber Track Undercarriage Manufacturers and Suppliers

● Main Applications of Rubber Track Undercarriage Systems in Thailand

● Key Factors When Selecting Rubber Track Undercarriage Manufacturers and Suppliers

● How Kemer Can Serve the Thai Market

● Sustainability and Environmental Benefits of Rubber Track Systems

● Maintenance Best Practices for Rubber Track Undercarriage Systems

● Future Outlook for Rubber Track Undercarriage Manufacturers and Suppliers in Thailand

● FAQ

>> 1. What do Rubber Track Undercarriage Manufacturers and Suppliers provide in Thailand?

>> 2. Why are rubber track undercarriage systems popular in Thailand?

>> 3. How can Kemer support Thai Rubber Track Undercarriage Manufacturers and Suppliers?

>> 4. What should buyers look for when choosing Rubber Track Undercarriage Manufacturers and Suppliers?

>> 5. How is the market for Rubber Track Undercarriage Manufacturers and Suppliers expected to grow?

Thailand is an important regional base for construction, agriculture, and infrastructure projects in Southeast Asia, which creates strong demand for professional Rubber Track Undercarriage Manufacturers and Suppliers. The Thailand construction equipment market was sized at 14,786 units in 2024 and is projected to reach 19,420 units by 2030, rising at a CAGR of approximately 4.6%, while the construction industry output is expected to grow by 5.9% in real terms in 2025 supported by public and private sector investments. For a global crawler solution provider like Kemer, understanding the role of Rubber Track Undercarriage Manufacturers and Suppliers in Thailand is essential to supporting local OEMs, dealers, and rental fleets with durable and efficient track undercarriage systems.

Thailand's economy is driven by construction, agriculture, and logistics, all of which rely heavily on tracked machinery operating on soft soil, rice fields, and unpaved roads. The global rubber track market is projected to grow from approximately $1.04 billion in 2025 to $1.63 billion by 2032, at a CAGR of 6.6%, reflecting the growing worldwide adoption of rubber track technology. As a result, the country depends on specialized Rubber Track Undercarriage Manufacturers and Suppliers that can deliver high-performance rubber track systems for excavators, compact track loaders, harvesters, and crawler carriers.

Rubber track technology helps Thai contractors and farmers reduce ground damage, improve traction on muddy or flooded terrain, and lower vibration and noise in urban projects. This is why demand for Rubber Track Undercarriage Manufacturers and Suppliers in Thailand continues to grow in both the OEM market and the replacement aftermarket. The earthmoving segment accounted for a significant share of the Thailand construction equipment market in 2024, with the segment estimated to reach 13.3 thousand units by 2030, creating substantial opportunities for undercarriage component suppliers.

Thailand's construction sector is experiencing robust recovery and growth. In May 2025, Thailand's manufacturing production index rose by 1.88% compared to May 2024, and the revival in the manufacturing sector is expected to directly fuel demand for construction equipment throughout the nation. The country has significantly invested in the modernization of ports with oil and gas projects, which is expected to drive equipment demand across multiple categories.

Thailand's automotive sector saw its first production increase in 21 months in May 2025, with output reaching 139,186 units, an increase of 10.32% annually, driven by a surge in battery electric vehicles and plug-in hybrid vehicles. This manufacturing recovery creates demand for material handling equipment and warehouses, expanding the use case for tracked machinery with rubber undercarriage systems in logistics and factory settings.

Meanwhile, Thailand's agricultural machinery market had a total value of THB 164.0 billion as of 2022, with domestically produced machinery totaling THB 116.6 billion. Agricultural machinery and parts are increasingly utilized in farming to boost land output, strongly encouraging landowners and farmers to incorporate automation solutions into their conventional agricultural techniques. The Thailand tractor market witnessed shipments of 58.39 thousand units in 2024 and is expected to reach 69.92 thousand units by 2030, further driving demand for Rubber Track Undercarriage Manufacturers and Suppliers serving the agricultural segment.

In Thailand, rubber track undercarriage assemblies are widely used on mini and midi excavators working on residential construction sites, canals, and utility works where low ground pressure is critical. Compact track loaders and multi-terrain loaders also rely on Rubber Track Undercarriage Manufacturers and Suppliers to deliver durable tracks that can operate on soft soil, sand, and landscaping surfaces without damaging finished pavements.

In agriculture, rice harvesters, paddy tractors, and crawler harvesters depend on rubber track undercarriage systems to provide flotation and traction in flooded or soft paddy fields. Thailand's agricultural sector is increasingly moving from manual labor to mechanized farming, driven by rural labor shortages and government support programs. This trend is boosting demand for small and medium-sized tractors and harvesters, particularly in rice, sugarcane, and cassava farming, all of which benefit from rubber track undercarriage systems that minimize soil compaction while maintaining mobility.

Many of these machines are imported from global brands, but Thailand's network of Rubber Track Undercarriage Manufacturers and Suppliers, distributors, and service centers ensures that replacement undercarriage components remain available throughout the equipment lifecycle. Leading construction equipment brands operating in Thailand include Caterpillar, Komatsu, Volvo CE, Hitachi Construction Machinery, SANY, Kubota, XCMG, and Kobelco, all of which utilize rubber track undercarriage systems on their compact equipment lines.

Thailand is supplied by a mixture of global rubber track producers, regional undercarriage specialists, and local wholesalers that focus on excavator and harvester parts. These Rubber Track Undercarriage Manufacturers and Suppliers typically provide complete rubber track belts, undercarriage components such as rollers and idlers, and sometimes complete rubber track undercarriage assemblies for OEMs and retrofits.

In addition to global brands, Thailand works with regional importers that source crawler undercarriage modules and parts from Asian manufacturing bases such as China and Japan. Companies like Kemer can support these channels by delivering integrated rubber track undercarriage systems that combine tracks, steel structures, planetary gearboxes, travel drives, and swing drives into a single engineered package.

Several local companies have built strong reputations as suppliers of undercarriage parts for excavators and harvesters, acting as important partners for global Rubber Track Undercarriage Manufacturers and Suppliers. These firms typically maintain large inventories of track chains, rubber tracks, sprockets, rollers, idlers, and wear parts to serve domestic retailers and contractors through one-stop service models.

For example, Thai wholesalers focusing on undercarriage components highlight their decades of experience in excavator and harvester parts, emphasizing standardized quality and technical support. Other Thai distributors position themselves as major suppliers of spare parts for heavy construction machinery, with large warehouse facilities to support ongoing infrastructure projects in Thailand and neighboring countries. Their ability to stock parts for multiple OEM brands makes them valuable partners for Rubber Track Undercarriage Manufacturers and Suppliers seeking local market access.

Global Rubber Track Undercarriage Manufacturers and Suppliers serve Thailand both through direct OEM relationships and via local distributors that stock tracks and undercarriage components for different machine brands. These suppliers often provide engineered rubber track designs, optimized tread patterns, and carcass constructions tailored to Southeast Asian soil conditions and climate.

Kemer, as a crawler solution specialist, can collaborate with Thai distributors and OEMs by delivering complete rubber track undercarriage modules, hydraulic motors, planetary gearboxes, and travel drives matched to local applications. Working with established Thai wholesalers, Kemer can help ensure that customers across construction, agriculture, and mining receive undercarriage systems that balance durability, cost, and ease of maintenance.

Within the last 20 years, quality brand rubber track life and efficiencies has doubled as a result of improved raw materials and technology. Tread designs and rubber compounding define recent trends, leading to longer-lasting, smoother running tracks that benefit operators in Thailand's demanding environments. Innovations in rubber compounds, reinforced core technologies, and noise-reducing tread designs are improving durability and ride quality across the industry.

The development of composite rubber tracks and advanced carcass technologies is enhancing vehicle mobility and reducing maintenance costs. Modern track technology includes continuous wound brass-coated cables, forged metal pieces, short pitch mini-excavator tracks, and cut-resistant rubber compounds that extend service life significantly. Advanced tread patterns have also been developed, including aggressive treads for muddy, snowy, or rough construction terrains and smooth treads for paved or hard-packed surfaces in urban construction and material handling applications.

These advancements benefit Rubber Track Undercarriage Manufacturers and Suppliers serving Thailand by providing products that last longer, require less frequent replacement, and perform better across the varied terrain types found in Thai construction and agricultural operations. As technology continues to improve, Thai customers can expect rubber track undercarriage systems that offer greater durability, lower noise, and improved fuel efficiency.

Choosing reliable Rubber Track Undercarriage Manufacturers and Suppliers in Thailand helps end users reduce machine downtime, avoid premature track failures, and maintain stable traction across varying terrain. Professional suppliers also ensure that rubber track undercarriage systems match OEM specifications, including pitch, width, carcass reinforcement, and tread pattern, which is essential for safety and smooth operation.

Rubber tracks provide several key advantages over steel tracks in many Thai applications. They offer a high level of traction on a variety of surfaces and are best on grass or dirt while limiting damage to paved surfaces. Lower noise due to less vibration makes them ideally suited for urban construction where noise ordinances apply. They also provide greater flotation, allowing operators to work in less than ideal weather conditions such as Thailand's monsoon season.

Global Rubber Track Undercarriage Manufacturers and Suppliers can additionally provide engineering support for special applications such as drilling rigs, crawler carriers, and custom platforms that operate in remote or harsh sites. By integrating hydraulic drives, planetary gearboxes, and control systems, solution providers like Kemer help Thai customers deploy fully engineered crawler platforms rather than sourcing individual components separately.

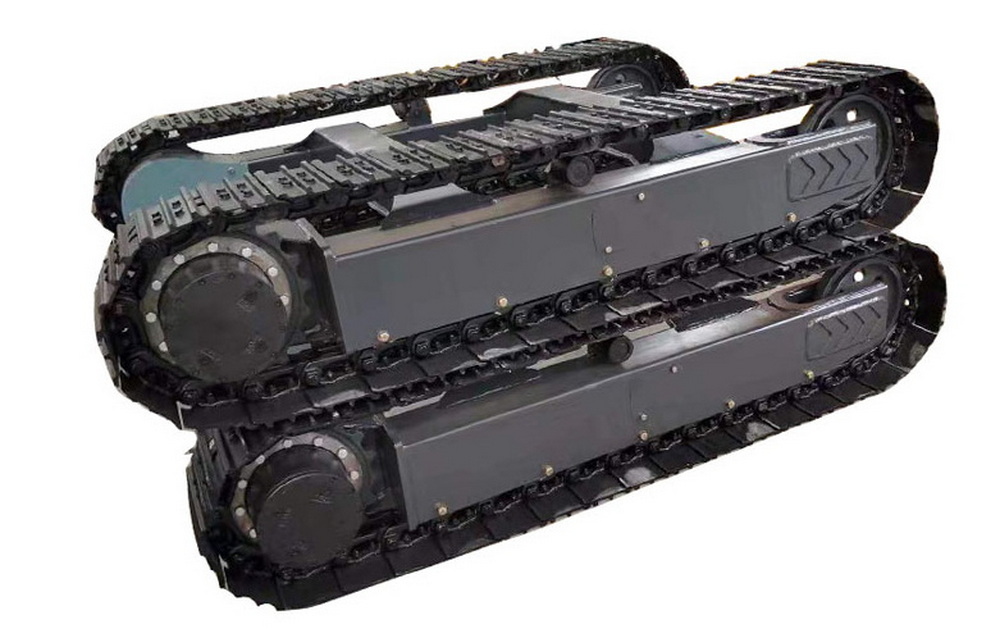

Rubber Track Undercarriage Manufacturers and Suppliers that serve Thailand generally offer a portfolio including rubber tracks, track frames, bottom and top rollers, drive sprockets, idlers, and track tensioning components. Many also stock undercarriage parts for multiple OEM brands to support mixed fleets of excavators, compact track loaders, and harvesters.

Some global Rubber Track Undercarriage Manufacturers and Suppliers provide complete bolt-on undercarriage modules that can be used by equipment builders and integrators to develop new tracked machines quickly. Kemer's capability to combine rubber track undercarriage systems with hydraulic winches, swing drives, and travel drives is particularly valuable for OEMs who want a single partner for the entire crawler and transmission package.

In urban construction, rubber track undercarriage systems are used on compact excavators, track loaders, and small drilling rigs working on tight or sensitive job sites with concrete and asphalt surfaces. These machines benefit from low ground disturbance and low vibration, which protects pavements and reduces complaints from nearby residents. As Thailand continues to develop its urban infrastructure, including projects like the Suvarnabhumi Airport expansion, demand for low-impact tracked equipment will continue growing.

In agriculture, rubber track undercarriage solutions are critical for rice harvesters, paddy tractors, and sugarcane or plantation equipment that must operate in wet, soft, or uneven fields. Rubber Track Undercarriage Manufacturers and Suppliers help Thai farmers increase productivity by offering tracks that maintain traction in muddy conditions while limiting soil compaction that can damage crops. The rising adoption of automated and semi-automated fertilization and planting equipment is also fueling the demand for advanced machinery equipped with rubber track undercarriage systems.

Buyers in Thailand evaluating Rubber Track Undercarriage Manufacturers and Suppliers should consider quality certifications, production experience, and track design features such as carcass reinforcement, steel cord design, and tread pattern. Suppliers with proven performance in construction and agriculture tend to provide longer wear life, fewer de-tracking issues, and better resistance to cuts and tearing.

Availability of local inventory and after-sales service is another critical factor when choosing Rubber Track Undercarriage Manufacturers and Suppliers. Thai wholesalers with large warehouses and technical teams can help customers quickly replace worn tracks and diagnose undercarriage problems, while international partners like Kemer back them up with engineering support and OEM-level documentation.

Additionally, buyers should evaluate whether suppliers can provide integrated solutions that combine rubber tracks with travel drives, swing drives, and planetary gearboxes. This integrated approach simplifies procurement, ensures component compatibility, and provides a single point of contact for technical support throughout the equipment lifecycle.

Kemer specializes in crawler undercarriage systems, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors that are well suited to the needs of Thai construction and agricultural equipment manufacturers. By working with local Rubber Track Undercarriage Manufacturers and Suppliers and distributors, Kemer can deliver complete undercarriage packages that integrate rubber tracks, steel frames, and drive components.

For Thailand-focused OEMs and system integrators, partnering with Kemer allows them to shorten development cycles for new tracked machinery and ensure that each rubber track undercarriage system is correctly sized for load, speed, and duty cycle. At the same time, Kemer's global experience in challenging environments helps Thai fleets improve reliability and reduce lifecycle costs across their tracked equipment.

As construction equipment manufacturers increasingly launch battery-powered equipment in the Southeast Asian market including Thailand, Kemer can support this transition by providing undercarriage and drive systems compatible with electric and hybrid power sources. In line with initiatives like Thailand 4.0, construction contractors are actively seeking alternatives to conventional diesel-powered construction machinery, creating opportunities for forward-thinking Rubber Track Undercarriage Manufacturers and Suppliers.

Rubber tracks cause less environmental damage compared to steel tracks, aligning with global sustainability goals that are increasingly important to Thai contractors and equipment buyers. The lower ground pressure provided by rubber track undercarriage systems reduces soil compaction in agricultural applications, helping maintain soil health and productivity over time.

In urban environments, rubber tracks minimize pavement damage and reduce the noise pollution associated with construction activities. As Thailand's cities continue to grow and construction projects increasingly take place in populated areas, these environmental benefits make Rubber Track Undercarriage Manufacturers and Suppliers essential partners for sustainable development.

To maximize the value of investments in Rubber Track Undercarriage Manufacturers and Suppliers, Thai operators should follow best practices for track and undercarriage maintenance. This includes maintaining correct track tension, regularly cleaning mud and debris from roller and sprocket areas, and inspecting for cuts, exposed cords, or abnormal wear patterns.

Working with reputable Rubber Track Undercarriage Manufacturers and Suppliers also ensures access to technical guidance about alignment, roller replacement intervals, and operating limitations such as maximum travel speed and turning on abrasive surfaces. Kemer's experience with travel drives, swing drives, and undercarriage structures enables it to advise Thai customers on how to match hydraulic performance with rubber track characteristics for longer service life.

Standard rubber tracks may last between 1,200 and 1,600 hours with standard use, making it cost-effective to maintain relationships with reliable Rubber Track Undercarriage Manufacturers and Suppliers who can provide timely replacements when needed.

Analysts expect the rubber track market to keep expanding as more compact equipment and agricultural machines adopt rubber track undercarriage systems worldwide, especially in Asia Pacific. Thailand's continued infrastructure spending, urban development, and agricultural modernization will therefore sustain demand for professional Rubber Track Undercarriage Manufacturers and Suppliers over the coming decade.

Technological improvements, including stronger rubber compounds, more advanced tread designs, and better bonding between rubber and steel reinforcement, will further enhance the performance of rubber track undercarriage systems. The government's focus on strategies to double agricultural export volumes and revenues by 2030 will positively affect industry demand for mechanized farming equipment, including harvesters and tractors with rubber track undercarriage systems.

Global companies like Kemer can leverage these advances to supply Thailand with robust, integrated crawler solutions that cover undercarriage structures, drives, and hydraulic systems. As the construction and agricultural machinery markets continue to mature, Rubber Track Undercarriage Manufacturers and Suppliers that offer comprehensive product lines, technical expertise, and reliable local support will be best positioned to capture growth in the Thai market.

Thailand's expanding construction and agricultural sectors make it a strategic market for Rubber Track Undercarriage Manufacturers and Suppliers. With the construction equipment market projected to reach 19,420 units by 2030 and the agricultural machinery sector continuing to modernize, demand for rubber track undercarriage systems will remain strong. Local wholesalers, regional distributors, and global undercarriage specialists all play complementary roles in supplying rubber tracks, undercarriage parts, and complete crawler modules that keep Thai fleets productive.

By partnering with qualified Rubber Track Undercarriage Manufacturers and Suppliers and working with integrated solution providers like Kemer, Thai OEMs, contractors, and farmers can deploy machines that offer excellent traction, low ground pressure, and long service life in demanding conditions. As technology advances and demand rises, Thailand will continue to rely on Rubber Track Undercarriage Manufacturers and Suppliers that combine strong product engineering, consistent quality, and responsive local service.

Rubber Track Undercarriage Manufacturers and Suppliers provide rubber tracks, undercarriage components such as rollers, idlers, and sprockets, and sometimes complete rubber track undercarriage modules for excavators, loaders, and harvesters. In Thailand, these suppliers serve both OEM machinery builders and the replacement market through wholesalers and distributors. They may also offer engineering support for custom applications and integrated drive systems.

Rubber track undercarriage systems are popular in Thailand because they reduce ground damage, improve traction on soft or wet soil, and lower vibration and noise on urban construction sites. These benefits are especially important for rice paddies, plantation farming, and city infrastructure projects where conventional steel tracks can cause excessive disturbance. Additionally, rubber tracks provide greater flotation during Thailand's monsoon season, allowing work to continue in less than ideal weather conditions.

Kemer can support Thai Rubber Track Undercarriage Manufacturers and Suppliers by providing integrated crawler modules that combine rubber tracks, undercarriage frames, planetary gearboxes, travel drives, and hydraulic motors. Working alongside local distributors, Kemer helps Thai OEMs and fleets obtain engineered undercarriage solutions that balance durability, cost, and performance. Kemer's expertise in tracked chassis and drive systems allows it to serve as a single-source partner for complete crawler system requirements.

Buyers should evaluate Rubber Track Undercarriage Manufacturers and Suppliers based on quality standards, track design features, proven performance in similar applications, and the availability of local stock and technical support. Key track design factors include carcass reinforcement, tread pattern, and steel cord construction. Suppliers with strong engineering capabilities and established service networks in Thailand can help minimize downtime and ensure compatibility with OEM equipment.

The market for Rubber Track Undercarriage Manufacturers and Suppliers is forecast to grow steadily as global rubber track demand increases, particularly in Asia Pacific. The global rubber track market is projected to reach $1.63 billion by 2032, growing at a CAGR of 6.6%. With ongoing infrastructure and agricultural investments, Thailand will remain an attractive destination for Rubber Track Undercarriage Manufacturers and Suppliers that can offer high-quality products and reliable distribution.

1. https://market.us/report/global-rubber-track-market/

2. https://www.marketsandmarkets.com/Market-Reports/rubber-track-market-236156766.html

3. https://www.thongchai-equip.com/en/

4. https://www.trackequipment.co.th/home-EN

5. https://www.itrworld.com/rubber-tracks/

6. https://www.vematrack.com/en/product-groups/complete-undercarriages/

7. https://www.crawlerundercarriage.com/rubber-track-undercarriage-manufacturers/

8. https://www.polarismarketresearch.com/industry-analysis/undercarriage-components-market

9. https://www.globalinsightservices.com/insight/top-10-companies-in-the-rubber-track-market/

10. https://www.researchandmarkets.com/reports/5549997/thailand-construction-equipment-market-research

11. https://finance.yahoo.com/news/thailand-construction-industry-report-2025-130500932.html

12. https://www.gmiresearch.com/report/thailand-agricultural-machinery-market/

13. https://www.krungsri.com/en/research/industry/industry-outlook/agriculture/agricultural-machinery/io/agriculture-machinery-2024-2026

14. https://www.arizton.com/market-reports/thailand-tractors-market

15. https://www.accio.com/business/trend-of-rubber-tracks

16. https://www.forconstructionpros.com/equipment/fleet-maintenance/undercarriage/article/22872250/heavy-equipment-undercarriages-tracks-advancements

17. https://industrialtire.org/the-rise-of-rubber-tracks-in-material-handling-and-construction-equipment-trends-and-innovations/

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey