Views: 222 Author: Robert Publish Time: 2026-01-19 Origin: Site

Content Menu

● Why Rubber Track Undercarriage Matters in Kazakhstan

● Overview of Rubber Track Undercarriage Supply in Kazakhstan

● Kemer as a Leading Rubber Track Undercarriage Partner

● Kemer's Product Portfolio for Kazakhstan

>> Rubber Track Undercarriage Systems

>> Steel Track Undercarriage for Heavy Duty

>> Hydraulic Winches and Winch Drives

>> Planetary Gearboxes, Travel Drives, and Swing Drives

● Key Advantages of Kemer for Kazakh Buyers

>> Custom Engineering and Flexible Design

>> Integrated Crawler and Hydraulic Systems

>> Durability in Harsh Environments

>> Global Experience with Local Relevance

● How to Choose Rubber Track Undercarriage Manufacturers and Suppliers in Kazakhstan

>> Assessing Technical Fit and Performance

>> Evaluating Product Range and System Integration

>> Considering Service, Lead Time, and Lifecycle Cost

>> Checking Certifications and Quality Assurance

● Typical Applications of Rubber Track Undercarriage in Kazakhstan

● Best Practices for Operating and Maintaining Rubber Track Undercarriage

● Why Kemer Stands Out Among Rubber Track Undercarriage Manufacturers and Suppliers

● FAQ on Rubber Track Undercarriage Manufacturers and Suppliers in Kazakhstan

>> 1. Why choose rubber track undercarriage instead of steel for some Kazakh projects?

>> 2. What makes Kemer different from other Rubber Track Undercarriage Manufacturers and Suppliers?

>> 3. Can Kemer customize rubber track undercarriage solutions for local Kazakh applications?

>> 4. How should Kazakh buyers evaluate Rubber Track Undercarriage Manufacturers and Suppliers?

>> 5. Which industries in Kazakhstan benefit most from Kemer's rubber track undercarriage systems?

Kazakhstan's fast‑growing construction, mining, energy, and infrastructure sectors rely heavily on tracked machinery, which makes the choice of reliable Rubber Track Undercarriage Manufacturers and Suppliers a strategic decision for contractors and equipment OEMs in the region. As project owners push into tougher terrain and more remote areas, they increasingly need durable, low‑maintenance rubber track undercarriage solutions that combine long service life with low ground pressure and good operator comfort.

Kazakhstan has become an attractive market for global and regional undercarriage specialists, including Kemer, that provide integrated crawler systems, hydraulic drives, and winch solutions for a wide range of mobile equipment. By working with experienced Rubber Track Undercarriage Manufacturers and Suppliers, local companies can improve machine uptime, reduce operating costs, and safely tackle more demanding jobs year‑round.

Rubber tracks play a critical role in how modern machinery interacts with Kazakhstan's varied ground conditions. Compared with traditional steel tracks, rubber track undercarriage systems significantly reduce ground pressure, protect sensitive surfaces, and lower noise and vibration levels. This makes them particularly valuable for work in city centers, residential areas, industrial facilities, and agricultural land where surface damage and environmental disturbance must be minimized.

At the same time, high‑quality rubber track undercarriage systems are engineered to withstand the country's harsh seasonal climate, including hot summers, freezing winters, and abrasive soils. When sourced from experienced Rubber Track Undercarriage Manufacturers and Suppliers, these systems provide the traction, stability, and durability needed on construction sites, mine access roads, pipeline corridors, wind farm locations, and other remote projects.

The rubber track undercarriage market in Kazakhstan is supported by a combination of OEM dealers, independent distributors, and specialist international manufacturers. Official dealers of global brands supply complete machines and genuine undercarriage components for large fleets, while regional distributors import aftermarket tracks, chains, rollers, idlers, sprockets, and segments for replacement and upgrade purposes.

Alongside these, specialist Rubber Track Undercarriage Manufacturers and Suppliers—primarily from China and Europe—ship complete crawler assemblies and custom undercarriage packages into Kazakhstan. Many of these packages include integrated travel drives, planetary gearboxes, and hydraulic motors, enabling equipment builders and retrofitting companies in Kazakhstan to install turnkey crawler solutions tailored to local performance requirements.

This multi‑layered network gives Kazakh buyers the flexibility to choose between genuine OEM parts, cost‑effective aftermarket options, and fully customized rubber track undercarriage systems depending on project type, budget, and lifecycle priorities.

Kemer is a specialized engineering manufacturer focusing on crawler systems and hydraulic transmission solutions for global OEMs and project contractors. As one of the dedicated Rubber Track Undercarriage Manufacturers and Suppliers serving Kazakhstan and other international markets, Kemer offers a broad range of products that cover both the mechanical and hydraulic sides of tracked machinery.

The company designs and manufactures steel tracked undercarriage and rubber track undercarriage platforms that can carry loads from small compact machines up to heavy industrial equipment. These crawler systems are complemented by travel drives, swing drives, winch drives, planetary gearboxes, and hydraulic motors, allowing Kemer to deliver fully matched driveline solutions rather than isolated parts.

For Kazakhstan, this combination of crawler undercarriage expertise and transmission technology is particularly valuable, because machine builders and retrofitters can rely on a single partner for undercarriage frames, tracks, and drive components that are engineered to work together.

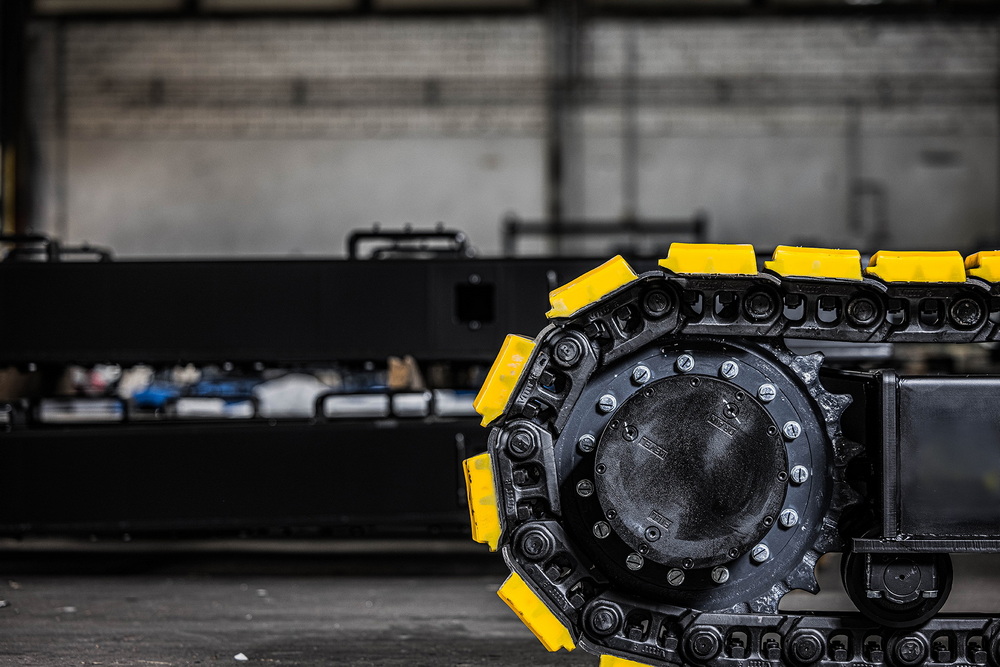

Kemer produces complete rubber track undercarriage systems for compact and mid‑sized machinery, typically covering load capacities from around 1 ton up to approximately 10 tons, depending on configuration. These systems are suitable for mini‑excavators, small drilling rigs, aerial work platforms, agricultural machines, utility equipment, and a variety of special‑purpose vehicles.

The rubber track undercarriage designs emphasize wear resistance, tear resistance, and oil resistance while providing low ground pressure and reduced surface damage on asphalt, concrete, and landscaped areas. By working closely with customers, Kemer can adjust frame length, overall width, track width, roller arrangement, and mounting interfaces so that each rubber track undercarriage fits the machine layout and the terrain conditions encountered in Kazakh projects.

Thanks to this customization capability, Kemer has become a preferred partner among Rubber Track Undercarriage Manufacturers and Suppliers for OEMs and contractors who require application‑specific crawler solutions rather than generic or one‑size‑fits‑all systems.

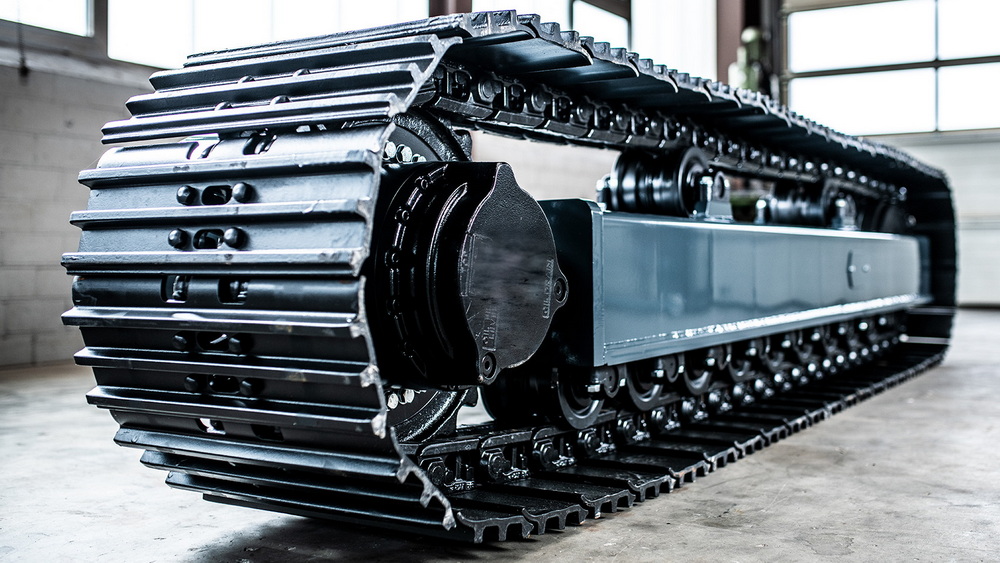

In addition to rubber products, Kemer manufactures steel tracked undercarriages with load capacities that can span from roughly 2 tons to around 60 tons depending on the model and configuration. These heavy‑duty crawler frames are commonly used for full‑size excavators, crawler cranes, large drilling rigs, crushers, foundation equipment, and other heavy industrial machinery.

On many large projects in Kazakhstan, steel undercarriage machines handle the heaviest duties, while lighter equipment uses rubber track undercarriage systems on more sensitive or finished surfaces. By supplying both types from one source, Kemer enables fleet owners to standardize on a single group of Rubber Track Undercarriage Manufacturers and Suppliers for the majority of their tracked equipment, simplifying spare parts management and technical support.

Kemer develops hydraulic winches and winch drives used for lifting, pulling, anchoring, and tensioning tasks in construction, drilling, marine, and industrial applications. The product range covers different pull capacities and drum configurations designed to integrate with mobile machinery such as drilling rigs, service cranes, pipe layers, and recovery vehicles.

These winches are engineered together with Kemer's planetary gearboxes and hydraulic motors to provide compact, high‑torque solutions that match the performance of the tracked carriers they are mounted on. For customers in Kazakhstan, this means they can combine rubber track undercarriage platforms and hydraulic winch systems from a single engineering supplier, ensuring proper torque, speed, and safety characteristics for demanding field operations.

Kemer's planetary gearboxes cover a wide range of applications, including final drives for track crawlers, wheel drives, winch drives, swing drives, and other mobile machinery functions. The gearboxes are designed for high torque density, compact size, and efficient power transmission, which are critical features when installing them into rubber track undercarriage frames with limited space.

By integrating planetary gearboxes with hydraulic motors, Kemer provides travel drives that can be configured in single‑speed or two‑speed versions to meet different speed and torque requirements. These travel drives are commonly mounted inside or alongside the undercarriage structure to protect them from mechanical damage and environmental exposure. Swing drives and winch drives built on similar planetary technology allow Kemer to offer a consistent, modular driveline architecture that simplifies design and maintenance for OEM customers.

A major advantage of working with Kemer compared with many other Rubber Track Undercarriage Manufacturers and Suppliers is the company's willingness and capability to provide custom engineering. Kemer can tailor undercarriage dimensions, mounting plates, track widths, and roller configurations in line with customer drawings and performance targets.

For machine builders in Kazakhstan, this is particularly important when designing or upgrading equipment for local ground conditions, such as soft soils, mixed gravel, or partially frozen surfaces. Custom rubber track undercarriage design allows them to optimize stability, traction, and ground pressure while fitting within the structural constraints and weight distribution of the base machine.

Kemer's integrated approach means customers can source crawler frames, rubber and steel tracks, hydraulic motors, planetary gearboxes, winch drives, travel drives, and swing drives from one coordinated supplier. This reduces the engineering complexity that often arises when components are purchased from multiple vendors and then combined into a single machine.

By handling both mechanical and hydraulic design, Kemer improves the likelihood that the rubber track undercarriage, travel drives, and winches will deliver smooth startup, controlled acceleration, appropriate braking, and efficient power usage under real‑world operating conditions. For Kazakh customers, this translates into improved reliability, easier troubleshooting, and streamlined procurement.

Kazakhstan's operating environments can be extremely demanding, with wide temperature swings, dust, mud, and abrasive materials present on many sites. Kemer's focus on heavy‑duty construction, protective shielding for hydraulic components, and durable rubber compounds helps ensure that its rubber track undercarriage systems and steel crawler frames can cope with these conditions.

Using undercarriage solutions that are designed for harsh environments reduces unplanned downtime, prevents premature wear, and minimizes the risk of catastrophic component failures. For contractors and owners who operate far from major service centers, this level of durability is essential when selecting Rubber Track Undercarriage Manufacturers and Suppliers.

Kemer's experience with international OEMs and project owners enables it to apply proven crawler designs and driveline solutions to Kazakhstan's market while still adapting to local needs. The company's track record in supporting different sectors—such as construction, mining, tunneling, energy, and agriculture—gives Kazakh customers confidence that the rubber track undercarriage systems have been tested in comparable conditions elsewhere.

At the same time, cooperation with regional distributors and service providers helps Kemer ensure that its products can be supplied, installed, and maintained efficiently within Kazakhstan, reducing lead times and improving after‑sales support.

When evaluating Rubber Track Undercarriage Manufacturers and Suppliers, the first priority should be technical suitability. Buyers need to confirm that the supplier can provide undercarriage systems with the required load capacity, track width, roller arrangement, and travel speed, while also considering ground pressure and stability.

In Kazakhstan, it is especially important to check how the rubber track undercarriage will perform across seasonal changes and challenging terrains. This means asking for detailed technical data, design drawings, and, where possible, reference projects in similar operating conditions. Suppliers like Kemer that offer custom engineering can fine‑tune the design to match real‑world duty cycles and ground conditions, which helps maximize service life and performance.

Another key factor is the breadth of the supplier's product range. It is advantageous to work with Rubber Track Undercarriage Manufacturers and Suppliers that can provide both steel and rubber track undercarriage options, as well as complementary components such as travel drives, swing drives, and hydraulic winches.

A broad, integrated product portfolio reduces the need to coordinate multiple manufacturers and ensures that mechanical and hydraulic components are compatible. Kemer's ability to supply crawler frames, rubber tracks, planetary gearboxes, hydraulic motors, and winches from a single source is a strong example of how system integration can create value for OEMs and fleet operators.

Price is only one part of the decision when choosing Rubber Track Undercarriage Manufacturers and Suppliers in Kazakhstan. Buyers must also consider lead times, availability of spare parts, local service networks, and the overall lifecycle cost of the undercarriage systems.

A slightly higher initial investment can be justified if the supplier offers faster delivery, better technical support, and more durable products that lower repair and replacement costs over time. Working with a partner like Kemer that cooperates with regional distributors and maintains consistent quality standards helps minimize machine downtime and improves total cost of ownership.

Quality assurance practices and certifications provide additional confidence for customers who depend on their undercarriage systems for critical operations. Buyers should review whether their preferred Rubber Track Undercarriage Manufacturers and Suppliers operate under recognized quality management systems and maintain strict inspection and testing routines for components such as tracks, rollers, sprockets, gearboxes, and hydraulic motors.

By verifying these aspects during supplier evaluation, contractors and OEMs in Kazakhstan can reduce risk and ensure that their rubber track undercarriage investments meet required safety and performance standards.

Rubber track undercarriage systems are used in a wide variety of machines throughout Kazakhstan. Common applications include compact and mini‑excavators working in cities and industrial facilities, where reduced noise and surface protection are important. Rubber tracks are also widely used on compact loaders, small dumpers, and utility equipment operating on mixed surfaces.

In agriculture, rubber track undercarriage platforms support small tractors, sprayers, and special‑purpose machines that must travel over fields without compacting soil excessively. In energy, they are used for small drilling rigs, inspection platforms, and mobile equipment deployed around oil, gas, and renewable energy installations. The versatility of rubber track undercarriage solutions enables Kazakhstan's contractors to deploy equipment efficiently across different sectors without constantly switching machines or transport methods.

To get the most out of rubber track undercarriage systems from any of the leading Rubber Track Undercarriage Manufacturers and Suppliers, Kazakh users should follow some basic operating and maintenance practices. Regular inspection of track tension, roller condition, and sprocket wear is essential. Under‑tensioned tracks can derail, while over‑tensioned tracks increase wear and strain on the undercarriage structure.

Operators should avoid aggressive steering on abrasive surfaces whenever possible and clean the undercarriage regularly to remove built‑up mud, stones, and debris that can accelerate wear. For equipment operating under particularly harsh conditions, periodic technical inspections and preventive replacement of critical components can help prevent unexpected failures. Suppliers such as Kemer can provide guidelines and training materials tailored to the specific rubber track undercarriage models in use.

Kemer distinguishes itself through the combination of custom undercarriage design capabilities, integrated hydraulic drive solutions, and a strong focus on demanding applications. The company's product mix of rubber track undercarriage systems, steel crawlers, travel drives, swing drives, planetary gearboxes, and hydraulic winches allows it to function as a complete drive system provider for tracked machinery.

For Kazakhstan's market, this means that OEMs, retrofitting specialists, and large contractors can build long‑term cooperation with a single partner capable of supporting both existing machines and new equipment designs. With flexible engineering services, competitive load ranges, and a commitment to quality, Kemer has positioned itself as one of the most capable Rubber Track Undercarriage Manufacturers and Suppliers serving Central Asia and global customers.

Kazakhstan's construction, mining, energy, and agricultural industries depend on reliable crawler systems to keep projects on schedule and within budget. Choosing the right Rubber Track Undercarriage Manufacturers and Suppliers is therefore a key strategic decision that directly affects machine uptime, safety, and lifecycle cost. High‑quality rubber track undercarriage solutions help protect ground surfaces, reduce noise, and provide stable traction across the country's diverse terrains and extreme seasonal conditions.

With an extensive range of rubber and steel track undercarriage systems, planetary gearboxes, hydraulic motors, winch drives, travel drives, and swing drives, Kemer offers a comprehensive portfolio tailored to the needs of OEMs and contractors in Kazakhstan. By providing custom engineering, integrated mechanical and hydraulic solutions, and strong support for harsh environments, Kemer stands out as a trusted long‑term partner among global Rubber Track Undercarriage Manufacturers and Suppliers.

Rubber track undercarriage systems are ideal for projects where surface protection, reduced noise, and operator comfort are priorities. They exert lower ground pressure than steel tracks, which helps prevent damage to asphalt, concrete, and landscaped areas in cities and industrial zones. Rubber tracks also tend to generate less vibration, which reduces fatigue for operators and helps extend the life of machine components and nearby structures. For many light‑ and medium‑duty machines in Kazakhstan, this combination of advantages outweighs the higher peak durability of steel tracks.

Kemer stands out because it offers both crawler undercarriage structures and key hydraulic and mechanical drive components as a system, including planetary gearboxes, hydraulic motors, travel drives, swing drives, and winch drives. Instead of buyers having to coordinate multiple suppliers, Kemer provides integrated design support so that the rubber track undercarriage, steel crawler frames, and driveline components are matched from the start. This reduces engineering complexity, shortens development time, and improves reliability for equipment builders and end users in Kazakhstan.

Yes. Kemer can adapt frame length and width, track width, roller layout, mounting interfaces, and even certain drive parameters to match local application requirements. OEMs and contractors can provide technical data such as machine weight, center of gravity, expected travel speed, and typical ground conditions, and Kemer's engineering team will design a rubber track undercarriage configuration to fit. This custom approach ensures that equipment used in Kazakhstan operates efficiently on local soil types, slopes, and climate conditions rather than relying on generic designs.

Kazakh buyers should start by reviewing the technical specifications of the undercarriage solutions, verifying that the supplier can support required loads, track dimensions, speeds, and expected duty cycles. They should also consider whether the supplier offers both rubber and steel track options and provides integrated components such as travel drives and winches. Additional evaluation criteria include quality certifications, experience in similar industries, availability of spare parts, responsiveness of technical support, and lead times. Selecting suppliers with strong references and integrated product lines, such as Kemer, generally leads to better long‑term results.

Kemer's rubber track undercarriage solutions are particularly beneficial in industries where machines must work on mixed or delicate surfaces with frequent relocation. These include urban construction, industrial facility maintenance, utilities, agriculture, landscaping, and light drilling and geotechnical work. In these sectors, the combination of low ground pressure, reduced noise, and good mobility is especially valuable. For heavy construction, mining, and large energy projects, Kemer's steel crawlers and integrated transmission systems complement its rubber track offerings, enabling comprehensive support across a wide range of tracked equipment.

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey