Views: 222 Author: Robert Publish Time: 2026-01-18 Origin: Site

Content Menu

● What Is a Bonfiglioli Manufacturer in China?

● How Bonfiglioli Products Are Used

● 2. Kemer – Integrated Track and Drive Systems

● 3. Elephant Fluid Power Co., Ltd.

● 4. Shanghai SGR Heavy Industry Machinery Co., Ltd.

● 5. Foshan Dakota Hydraulic Co., Ltd.

● 6. Ningbo Victory Machinery Ltd.

● 7. Suzhou Dawang Transmission Equipment Co., Ltd.

● 8. Qingdao Elite Hydraulic Co., Ltd.

● 9. Qingdao LKC Hydraulic Machinery Co., Ltd.

● 10. Other Emerging Bonfiglioli‑Style Manufacturers

● Key Features of Bonfiglioli‑Style Planetary Gearboxes

● How to Select Bonfiglioli Manufacturers in China

● Benefits of Working with Chinese Bonfiglioli Manufacturers

● FAQ

>> 1. What products do Bonfiglioli Manufacturers in China mainly offer?

>> 2. How do official Bonfiglioli Manufacturers differ from compatible Chinese suppliers?

>> 3. Can Chinese Bonfiglioli Manufacturers customize gearboxes for special projects?

>> 4. What industries benefit most from working with Bonfiglioli Manufacturers in China?

Bonfiglioli is a global leader in planetary gearboxes, industrial gearmotors, winch drives, and complete drive systems used in construction, mining, marine, wind, and material handling industries. As demand for high‑torque, compact transmissions continues to rise, China has become a key base not only for Bonfiglioli's own operations but also for a network of Bonfiglioli Manufacturers and Bonfiglioli‑style drivetrain specialists serving OEMs worldwide.

This article introduces the Top 10 Bonfiglioli Manufacturers in China, including Bonfiglioli's official Chinese subsidiary, integrated system suppliers like Kemer, and several specialized planetary gearbox and winch drive factories that support similar applications. It explains what characterizes Bonfiglioli Manufacturers, where they are most competitive, how to evaluate them, and how global buyers can work with Chinese partners to create efficient, reliable drive solutions for mobile and industrial machinery.

In practical sourcing terms, “Bonfiglioli Manufacturers” in China can be divided into two main groups: official Bonfiglioli facilities operating under the Bonfiglioli brand, and independent Chinese factories producing planetary gearboxes, winch drives, travel drives, and gearmotors engineered for similar duty profiles as Bonfiglioli units. Both groups play important roles in global supply chains, but they differ in branding, certification, and typical application focus.

Official Bonfiglioli Manufacturers in China supply original Bonfiglioli products—the same planetary drives, industrial gearmotors, and winch gearboxes found in European and American markets—through localized assembly and support. Independent Bonfiglioli Manufacturers, by contrast, often design their planetary gearboxes and winch drives to be dimensionally or functionally close to Bonfiglioli products while offering additional flexibility in cost, customization, or lead time for certain projects.

Bonfiglioli planetary gearboxes and gearmotors are prominent in both mobile and industrial sectors, and Chinese Bonfiglioli Manufacturers typically mirror this application landscape. Understanding these uses helps buyers specify the right product families and identify which Bonfiglioli Manufacturers are best suited for each project.

- Mobile planetary drives

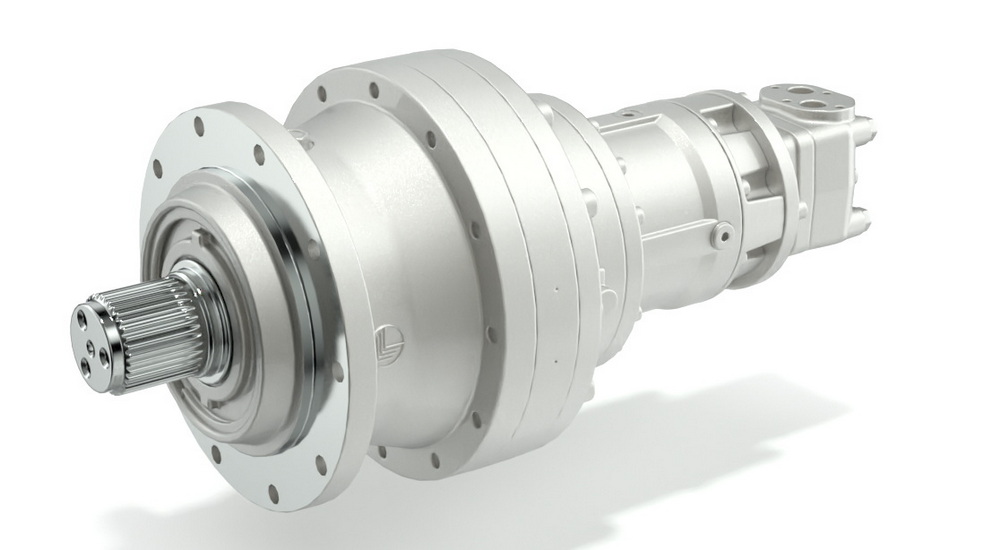

Bonfiglioli's 300 Series planetary drives are widely used in tracked undercarriages, drilling rigs, cranes, and mobile equipment where compact, high‑torque transmissions are required to withstand shocks and heavy loads. Chinese Bonfiglioli Manufacturers often target similar applications with travel drives, swing drives, and wheel drives inspired by these configurations.

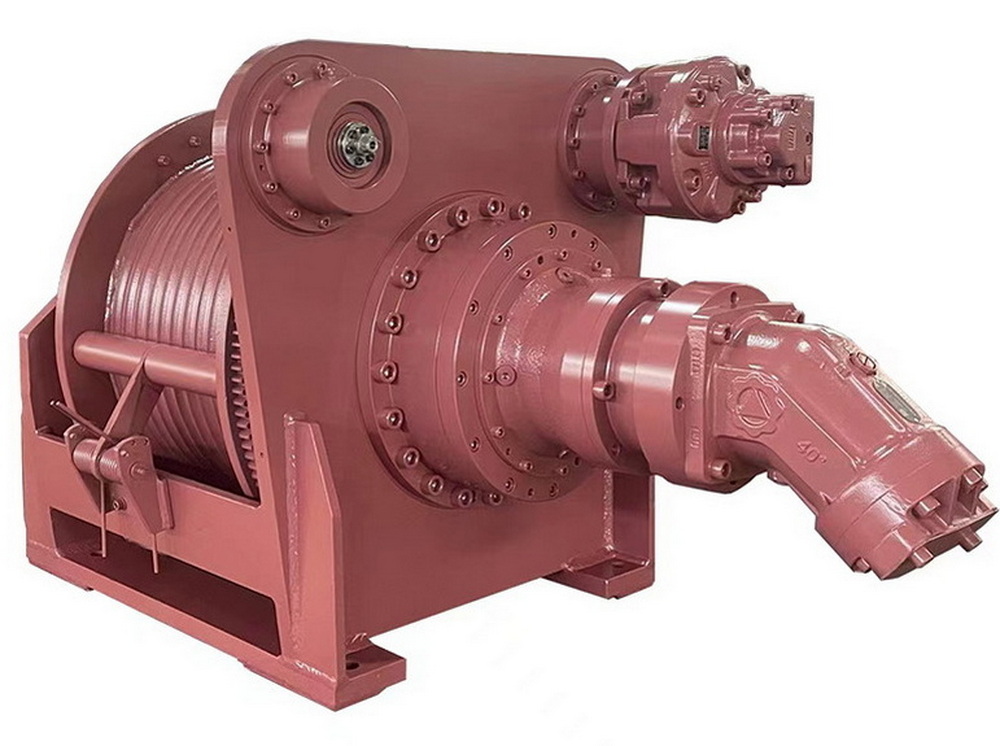

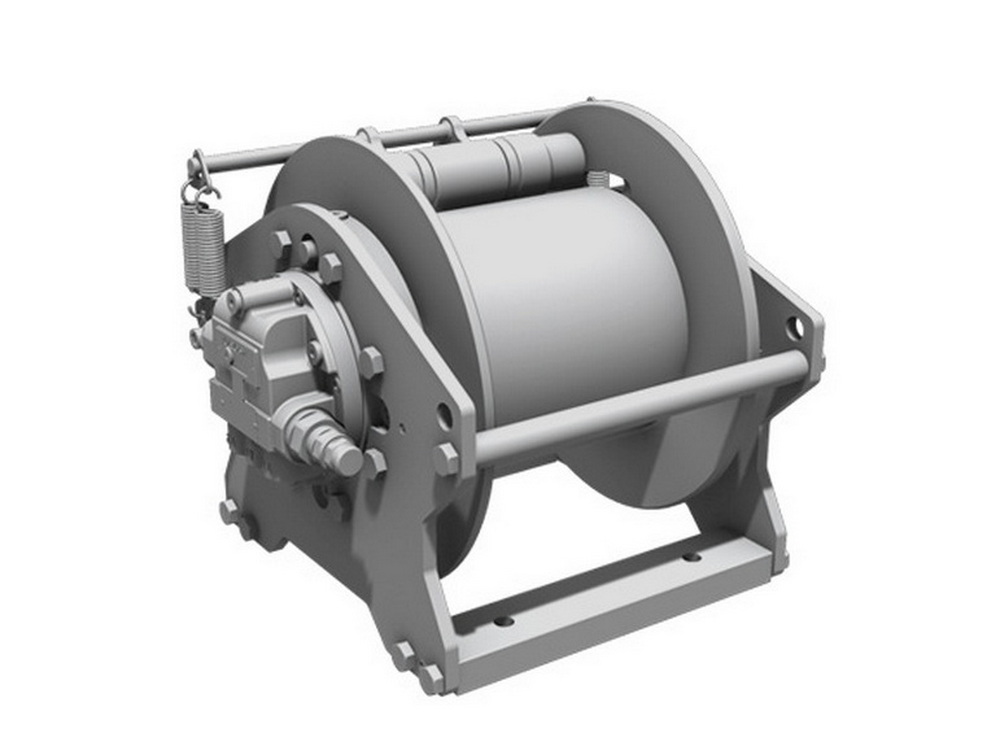

- Winch drives for marine and lifting

The Bonfiglioli FW Series planetary winch gearboxes are designed for marine cranes, offshore platforms, and deck machinery where high torque, integrated brakes, and robust bearings are critical. Chinese Bonfiglioli Manufacturers developing winch drives typically focus on similar FEM‑rated, heavy‑duty performance, producing winch gearboxes for construction hoists, ship cranes, and offshore handling systems.

- Industrial gearmotors and precision drives

Bonfiglioli's industrial portfolio covers helical, bevel‑helical, and planetary gearmotors, as well as precision planetary gearboxes for automation and motion control. Many Chinese Bonfiglioli Manufacturers support this segment by offering industrial planetary gearboxes and gearmotors suitable for conveyors, mixers, packaging lines, and storage systems.

Bonfiglioli entered China with a dedicated subsidiary in Shanghai, now operating under Bonfiglioli Transmission Equipment Co., Ltd., to provide local assembly, sales, and after‑sales service for the full range of Bonfiglioli products. Over the years, this facility has expanded to include modern assembly lines, testing equipment, and logistics operations that align with Bonfiglioli's global quality standards.

As one of the core official Bonfiglioli Manufacturers worldwide, Bonfiglioli China supplies mobile planetary gearboxes, wheel drives, winch drives, industrial gearmotors, and precision planetary units directly to OEMs and distributors in China and abroad. With direct access to Bonfiglioli's engineering teams and product portfolio, this subsidiary is the first choice for buyers seeking genuine Bonfiglioli components with local technical and commercial support.

Kemer is a Chinese manufacturer focused on tracked undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors for construction, mining, drilling, and special machinery. As an integrated system supplier, Kemer positions itself among Bonfiglioli Manufacturers that support complete drive solutions rather than just standalone planetary gearboxes.

By combining crawler chassis with planetary travel drives and hydraulic motors, Kemer helps OEMs shorten development cycles and align mechanical and hydraulic performance across the entire machine in a way comparable to integrated solutions from major Bonfiglioli Manufacturers. This makes Kemer especially attractive to international buyers who want Bonfiglioli‑style drive architectures with added flexibility for customized undercarriages, mounting interfaces, and winch configurations.

Elephant Fluid Power is often listed on industrial platforms as a supplier of planetary gear reducers and hydraulic components marketed as compatible with major brands, including Bonfiglioli. As one of the Bonfiglioli Manufacturers style companies, Elephant Fluid Power offers planetary gearboxes, travel drives, and replacement‑type gear units for cranes, excavators, and mobile equipment.

These products typically specify torque ranges, gear ratios, and input options similar to those of Bonfiglioli planetary drives, enabling OEMs and rebuilders to consider them as alternatives or complements to original units in certain applications. For buyers focused on value and flexibility, Elephant Fluid Power represents one of the more accessible Bonfiglioli Manufacturers in China.

Shanghai SGR Heavy Industry Machinery supplies a broad range of heavy‑duty gearboxes, including planetary gear units for cranes, construction equipment, and industrial machinery. As a supplier aligned with the typical product scope of Bonfiglioli Manufacturers, SGR offers heavy‑duty reducers designed for mixers, conveyors, and lifting equipment where compact planetary stages are essential.

Buyers sourcing from SGR often compare its planetary gearbox data—torque, ratio, input options, and mounting styles—with Bonfiglioli catalogs to evaluate functional equivalence or near‑equivalence. When supported by proper engineering review and testing, SGR's products can serve as competitive options alongside official Bonfiglioli Manufacturers for certain industrial and mobile applications.

Foshan Dakota Hydraulic focuses on hydraulic components and power transmission solutions, including hydraulic motors and valves used with planetary gearboxes in mobile machinery and winch systems. While not an official Bonfiglioli factory, Dakota acts as a complementary supplier among Bonfiglioli Manufacturers by providing hydraulic parts that interface smoothly with Bonfiglioli‑style planetary drives and winch gearboxes.

For OEMs designing complete hydraulic winch or travel drive systems, sourcing both the planetary gearbox and the hydraulic motor from compatible Bonfiglioli Manufacturers in China can significantly reduce integration effort. Dakota's experience in tailoring hydraulic configurations helps ensure that system efficiency and control behavior match the mechanical characteristics of the gearbox.

Ningbo Victory Machinery, located in Zhejiang province, appears in lists of Chinese suppliers offering gear reducers and planetary gearboxes in the same general market space as Bonfiglioli Manufacturers. The company focuses on gear units for cranes, hoists, and industrial machinery, where high torque density and compact layouts are critical.

Positioned within the broader Ningbo mechanical industry cluster, Victory can coordinate with multiple upstream and downstream partners, making it convenient for buyers who wish to assemble a regional supply chain of Bonfiglioli Manufacturers for winch drives, travel drives, and undercarriage components. Proximity to seaports also supports efficient export logistics.

Suzhou Dawang Transmission Equipment produces gearboxes and gearmotors that cover a range of helical and planetary designs compatible with many industrial applications. As one of the Bonfiglioli Manufacturers style competitors in East China, Dawang targets conveyor lines, mixers, and general process equipment that commonly use planetary or combined planetary/helical gearmotors.

From a sourcing standpoint, Dawang is often evaluated alongside Bonfiglioli industrial gearmotors and planetary units, with customers comparing efficiency, noise levels, torque density, and lifecycle cost. For certain non‑critical or cost‑sensitive installations, its products can provide a practical alternative to official Bonfiglioli Manufacturers.

Qingdao Elite Hydraulic supplies planetary winch drives and hydraulic motors for cranes, drilling rigs, and other equipment requiring high‑torque winches. Many of its products are marketed as Bonfiglioli‑type planetary gearboxes with similar mounting configurations and performance envelopes, making Elite a notable name among specialized Bonfiglioli Manufacturers in China.

Typical Elite winch drives indicate maximum output torque, ratio ranges up to high reduction values, dynamic and static factors, and brake integration details comparable to FW‑style planetary winch gearboxes. This positions Elite as a valuable partner for buyers needing Bonfiglioli Manufacturers experienced specifically in winch and hoisting technologies.

Qingdao LKC Hydraulic Machinery is widely recognized for track drives, swing drives, and hydraulic motors used in excavators and tracked machinery. While LKC operates under its own brand, its planetary travel and swing drives address many of the same mobile applications that official Bonfiglioli Manufacturers serve, such as excavators, drilling rigs, and crawler cranes.

International OEMs and replacement parts distributors often consider LKC alongside Bonfiglioli Manufacturers because of its focus on compact drives with high torque density, robust seals, and integration with standard undercarriage interfaces. Its product range supports a wide spectrum of tonnage classes and machine layouts.

Beyond these better‑known factories, numerous emerging Bonfiglioli Manufacturers in China specialize in niche segments such as wind turbine yaw and pitch drives, slewing gearboxes for cranes, or customized winch drives for offshore handling. These companies often combine planetary gear trains with special housings, tailored coatings, or integrated sensor options to meet demanding environmental and control requirements.

When considering such emerging Bonfiglioli Manufacturers, buyers should pay particular attention to reference projects, engineering capability, and quality assurance systems because production volumes may be lower and designs more customized. Comprehensive testing, joint development projects, and clear technical documentation help reduce risk when introducing specialized planetary gearboxes into mission‑critical applications.

Bonfiglioli planetary gearboxes and those produced by leading Bonfiglioli Manufacturers in China share several core design principles that make them suitable for severe‑duty mobile and industrial applications. Understanding these features helps engineers compare options and evaluate whether a given supplier truly operates at a Bonfiglioli‑level standard.

- High torque density and compact design

Planetary gear trains distribute load across multiple planets, allowing Bonfiglioli Manufacturers to deliver high output torque in relatively small housings. This compactness is crucial in tracked undercarriages, winch drums, and wheel drives where available space is limited.

- Flexible input and output configurations

Bonfiglioli planetary drives support hydraulic motors, IEC/NEMA electric motor adapters, solid shafts, splined shafts, and hollow shaft versions; many Chinese Bonfiglioli Manufacturers replicate this flexibility. This makes it easier to integrate gearboxes into both new designs and retrofit projects.

- Integrated brakes and bearings

Winch gearboxes such as the FW Series employ integrated disc brakes and robust taper roller bearings to handle cable pull and radial loads. Chinese Bonfiglioli Manufacturers focusing on winch drives typically incorporate similar brake and bearing concepts to achieve safe and long‑lasting operation.

- Wide ratio and frame size ranges

Bonfiglioli mobile planetary drives are produced in many frame sizes and reduction ratios, covering torque ranges from relatively small machines to heavy mining and construction equipment. Bonfiglioli Manufacturers in China often mirror this approach, offering finely spaced series so that OEMs can choose the most efficient size for each application.

Choosing the right Bonfiglioli Manufacturers in China involves more than comparing prices; technical compatibility, quality systems, and after‑sales service are equally important. The following points provide a structured approach for evaluating potential partners.

- Clarify whether you need official or compatible products

If your project requires certified original Bonfiglioli components, then an official facility such as Bonfiglioli China is the appropriate partner. If you are open to equivalent or Bonfiglioli‑style solutions, a wider range of Bonfiglioli Manufacturers, including Kemer and other Chinese factories, can be considered.

- Match technical specifications carefully

Request detailed datasheets showing torque ratings, ratios, thermal limits, input speeds, and mounting dimensions for planetary gearboxes and winch drives. Compare these values directly with Bonfiglioli documentation to confirm that the Bonfiglioli Manufacturers you choose can meet or exceed your application demands.

- Review quality management and testing

Visit or audit the factory when possible to confirm machining quality, assembly cleanliness, and test procedures for gearboxes, brakes, and bearings. Bonfiglioli Manufacturers with structured testing—such as load tests, noise measurement, and oil analysis—are better positioned to deliver consistent performance.

- Evaluate engineering support and customization

Strong Bonfiglioli Manufacturers provide application engineering, CAD models, and customization options for flanges, shafts, and auxiliary components. This support is especially important when integrating planetary gearboxes into complex tracked machines, cranes, or automated production lines.

- Consider logistics, service, and lifecycle cost

Lead time, spare parts availability, and local service partners strongly influence the total cost of working with Bonfiglioli Manufacturers. Buyers should balance initial price with long‑term support to avoid unnecessary downtime and maintenance headaches.

Chinese Bonfiglioli Manufacturers combine competitive pricing with broad technical capabilities and growing experience in global projects. When selected carefully, they can significantly enhance the value and performance of mobile and industrial machinery.

- Cost‑effectiveness and scalability

Localized assembly of Bonfiglioli products and the strong manufacturing base of compatible suppliers allow Chinese Bonfiglioli Manufacturers to offer attractive cost structures for small and large batches. This is especially valuable for OEMs aiming to remain competitive in price‑sensitive markets without sacrificing performance.

- Broad product coverage

Between official Bonfiglioli factories and compatible Bonfiglioli Manufacturers, global buyers can find planetary gearboxes, winch drives, wheel drives, gearmotors, and precision planetary units covering almost every major application segment. This broad coverage simplifies supplier management and technical coordination.

- Integrated systems and engineering collaboration

System‑oriented suppliers such as Kemer offer complete crawler undercarriage and drive modules, while other Bonfiglioli Manufacturers integrate hydraulic motors, electric motors, and controls into their gearbox offerings. This collaborative engineering approach allows OEMs to focus on machine architecture and performance rather than low‑level drivetrain integration details.

China has become a strategic hub for Bonfiglioli's global expansion and for the growth of complementary Bonfiglioli Manufacturers supplying planetary gearboxes, winch drives, and integrated drivetrain systems for demanding applications. From Bonfiglioli's own Shanghai subsidiary to integrated undercarriage specialists like Kemer and specialized factories in Shanghai, Ningbo, Suzhou, Foshan, and Qingdao, buyers can choose from a wide network of partners aligned with Bonfiglioli‑style technologies.

Selecting the right Bonfiglioli Manufacturers in China requires attention to technical details, quality systems, engineering support, and after‑sales infrastructure to ensure long‑term reliability and performance. When these factors are properly managed, cooperation with Chinese Bonfiglioli Manufacturers enables OEMs and project contractors to develop more compact, efficient, and competitive machines for the global market.

Bonfiglioli Manufacturers in China mainly provide planetary gearboxes, travel drives, swing drives, wheel drives, winch drives, and industrial gearmotors for mobile and industrial applications. Many also supply precision planetary gearboxes and complete drive packages combining gearboxes with electric or hydraulic motors and control solutions.

Official Bonfiglioli Manufacturers, such as Bonfiglioli China, produce and assemble genuine Bonfiglioli products under the company's global quality and branding standards. Compatible Chinese Bonfiglioli Manufacturers design their own planetary gearboxes and winch drives to match similar duty cycles and interfaces but operate under independent brands and specifications.

Yes, many Bonfiglioli Manufacturers in China offer customization options, including special ratios, unique flanges, shaft designs, seal configurations, and brake arrangements tailored to specific machinery. System‑oriented suppliers can also integrate the planetary gearbox with motors, undercarriages, and controls to form complete drive modules.

Industries that benefit strongly include construction machinery, mining and quarrying, marine and offshore, wind energy, and industrial processing and automation that all rely on compact, high‑torque planetary drives and gearmotors. Bonfiglioli Manufacturers in China support these sectors with solutions ranging from travel drives and winch gearboxes to precision planetary units for automated equipment.

International buyers should request detailed technical documentation, conduct factory audits when possible, and use sample testing or pilot orders to verify performance before large‑scale procurement. Engaging third‑party inspection agencies and monitoring field performance over time also helps ensure that chosen Bonfiglioli Manufacturers consistently meet project requirements.