Views: 222 Author: Robert Publish Time: 2026-01-18 Origin: Site

Content Menu

● Why China Leads in Planetary Winches

● Key Selection Criteria for Planetary Winch Manufacturers

● Top 10 Planetary Winch Manufacturers in China

>> 1. Ningbo Kemer Engineering Machinery Co., Ltd.

>> 3. Sino Hydraulic Drives & Transmissions

>> 4. Intech – Planetary Gearbox Hydraulic Winch Supplier

>> 6. Shandong Daixin Intelligent Technology Co., Ltd.

>> 7. Ningbo Bonny Hydraulics Transmission Co., Ltd.

>> 8. Jiangyin Zhongxin Engineering Equipment Co., Ltd.

>> 9. Various Planetary Winch Suppliers on B2B Platforms

>> 10. Other Specialized Chinese Planetary Winch Manufacturers

● Benefits of Choosing Chinese Planetary Winch Manufacturers

● Application Scenarios for Planetary Winch Manufacturers

● Practical Sourcing Tips for Planetary Winch Buyers

● FAQ – Planetary Winch Manufacturers

>> 1. What are the main advantages of sourcing from Chinese Planetary Winch Manufacturers?

>> 2. How do Planetary Winch Manufacturers ensure safety and reliability?

>> 4. Can Planetary Winch Manufacturers provide complete systems, not just the winch?

>> 5. How does Kemer position itself among Planetary Winch Manufacturers in China?

China is one of the most dynamic sourcing bases for planetary winch systems, offering competitive solutions for cranes, construction machinery, marine equipment, mining, and special vehicles. Planetary Winch Manufacturers in China combine compact planetary gearboxes, high-torque hydraulic motors, and robust drums to deliver reliable hoisting and pulling performance for global OEMs and engineering projects.

Among these Planetary Winch Manufacturers, Kemer stands out as a specialized producer of tracked undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors, serving customers worldwide with integrated motion and transmission solutions.

China's Planetary Winch Manufacturers benefit from strong industrial clusters for gear machining, casting, heat treatment, and hydraulic components, which helps control cost while maintaining performance. Many Chinese planetary winch suppliers combine winches with planetary gear reducers, hydraulic motors, and complete power packs, simplifying system integration for overseas buyers.

For global OEMs, sourcing from Planetary Winch Manufacturers in China offers advantages such as flexible customization, modular design, and faster delivery cycles for both standard and special-purpose winches. This makes Chinese planetary winch solutions attractive for applications like truck cranes, drilling rigs, aerial platforms, marine winches, and mining equipment.

When evaluating Planetary Winch Manufacturers, buyers usually focus on several technical and commercial factors to ensure long-term performance and reliability. These factors directly affect total lifecycle cost, safety, and compatibility with the host machine.

- Rated line pull and safety factor range suitable for the application .

- Planetary gearbox design .

- Integration level: hydraulic motor, brake, valve block, rope guide, and drum design.

- Sealing, corrosion protection, and environmental suitability .

- Certification, testing capability, and track record with international OEMs.

- Lead time, MOQ, engineering support, and after-sales service responsiveness.

Below is an overview-style list of representative Planetary Winch Manufacturers in China, highlighting typical strengths relevant to global buyers. The emphasis is on suppliers capable of integrating planetary gearboxes, hydraulic winches, and related drive components.

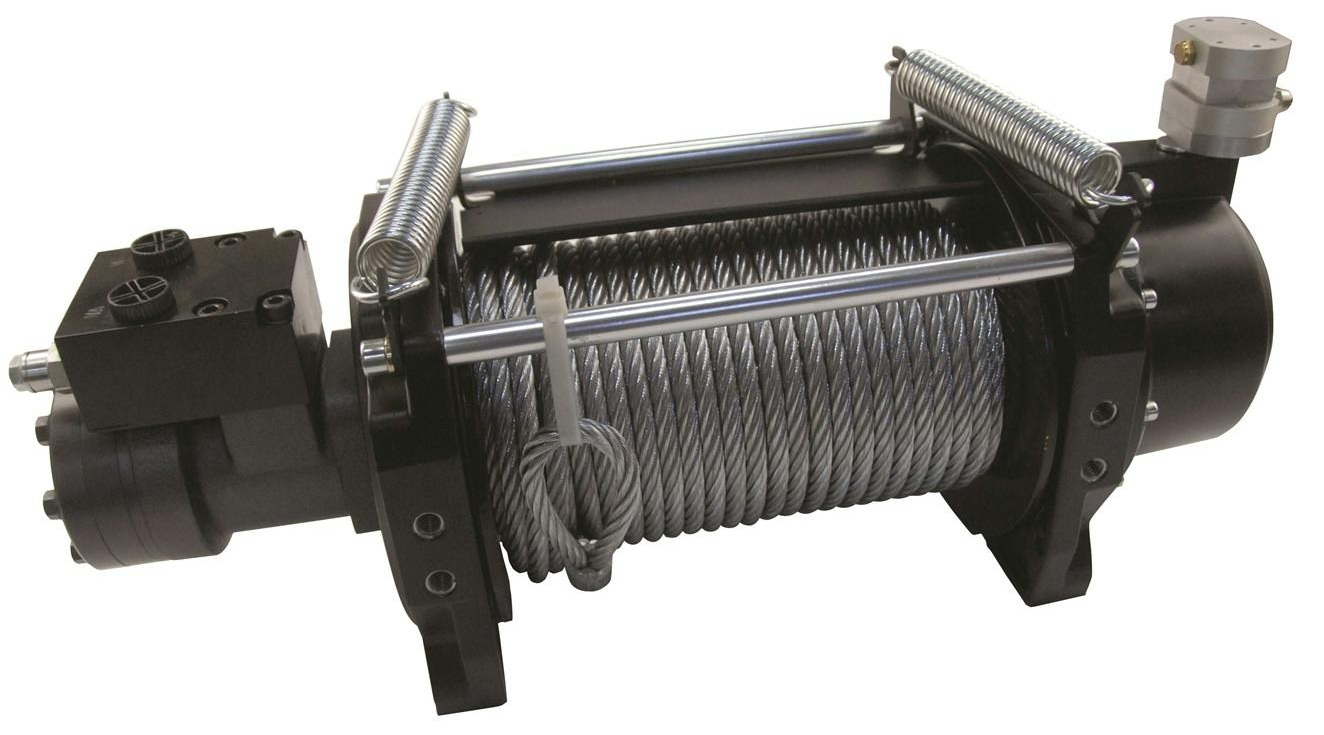

Ningbo Kemer is a dedicated manufacturer focusing on crawler track undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors for global customers, positioning itself as an integrated motion system provider. As one of the specialized Planetary Winch Manufacturers, Kemer offers high-speed hydraulic winches and windlasses built around planetary gear reducers, optimized for compact size, high torque density, and easy installation in mobile and marine equipment.

Kemer's planetary winch solutions can be engineered together with steel or rubber tracked undercarriages and travel drives, helping OEMs obtain a matched drive train from a single source and reduce engineering interfaces. The company's facility in Ningbo's Economic & Technical Development Zone supports large-volume production, with strict quality management aligned with ISO systems to ensure consistent planetary winch performance for international projects.

INI Hydraulic is one of the known Planetary Winch Manufacturers in China, supplying hydraulic winches, planetary gearboxes, and marine winches for deck machinery and offshore applications. The company offers series winches where hydraulic motors, multi-disc brakes, planetary gearsets, and optional valve blocks are tightly integrated into a compact package for cranes, hoists, and marine deck equipment.

INI Hydraulic emphasizes marine and offshore environments, providing planetary winch solutions that can be configured for anchor handling, towing, and handling boat equipment. Its portfolio of planetary gearboxes and marine winches allows system designers to match torque and speed requirements closely while retaining robust safety margins.

Sinohyd is listed among Chinese suppliers providing hydraulic winches, planetary winches, and hoisting winches used in cranes, aerial platforms, and process plants. As one of the Planetary Winch Manufacturers serving global projects, Sinohyd offers planetary winches in various line pulls and drum capacities, integrating hydraulic motors, multi-disc brakes, and planetary reducers to achieve compact and efficient lifting systems.

The company's winch lines are deployed worldwide in manufacturing plants and mobile equipment, indicating a mature design and application base. Sinohyd's focus on hydraulic transmission systems helps OEMs ensure that the planetary winch, hydraulic pumps, and control valves work together effectively.

Some Chinese Planetary Winch Manufacturers are strong in planetary gear technology, and Intech is an example focusing on planetary gearbox hydraulic winch combinations. Intech promotes hydraulic winch products integrated with planetary gearbox, drum, motor, and valve block, emphasizing compact structure, reduced weight, and high working pressure capability for crane and industrial applications.

Intech reports experience delivering planetary gearbox hydraulic winch solutions to multiple international markets, including Europe and the Americas, highlighting export experience and familiarity with overseas standards. Its ability to design planetary gear units for different torque and speed ranges helps buyers optimize planetary winch performance for each model.

Chongpeng Machinery, often promoted as CP Winch Group, is recognized as one of the notable winch manufacturers in China, involved in the formulation of winch production standards. While CP's portfolio includes electric winch, marine winch, mining winch, and construction winch, planetary-type winch drives are often part of its hoisting solutions for heavy-duty mining and industrial applications, placing it among broader Planetary Winch Manufacturers.

Being engaged in standard setting suggests a higher level of engineering capability and process control. CP Winch Group focuses on industrial and heavy-duty segments, where robust drum design, reliable braking, and strong planetary gearboxes are key decision factors for buyers.

Shandong Daixin appears in listings for planetary winches and planetary gear reducer winches, supplying hydraulic winches combined with planetary gear reducers for cranes and lifting equipment. Its product lines show hydraulic winch and planetary gear reducer solutions that can handle different tonnages, making it one of the Planetary Winch Manufacturers suitable for OEM cranes and construction machinery.

The company also engages in broader lifting equipment manufacturing, which suggests experience in matching planetary winch specifications to gantry cranes, overhead cranes, and similar machinery. Buyers who need both winches and crane structures often take advantage of this integrated supply capability.

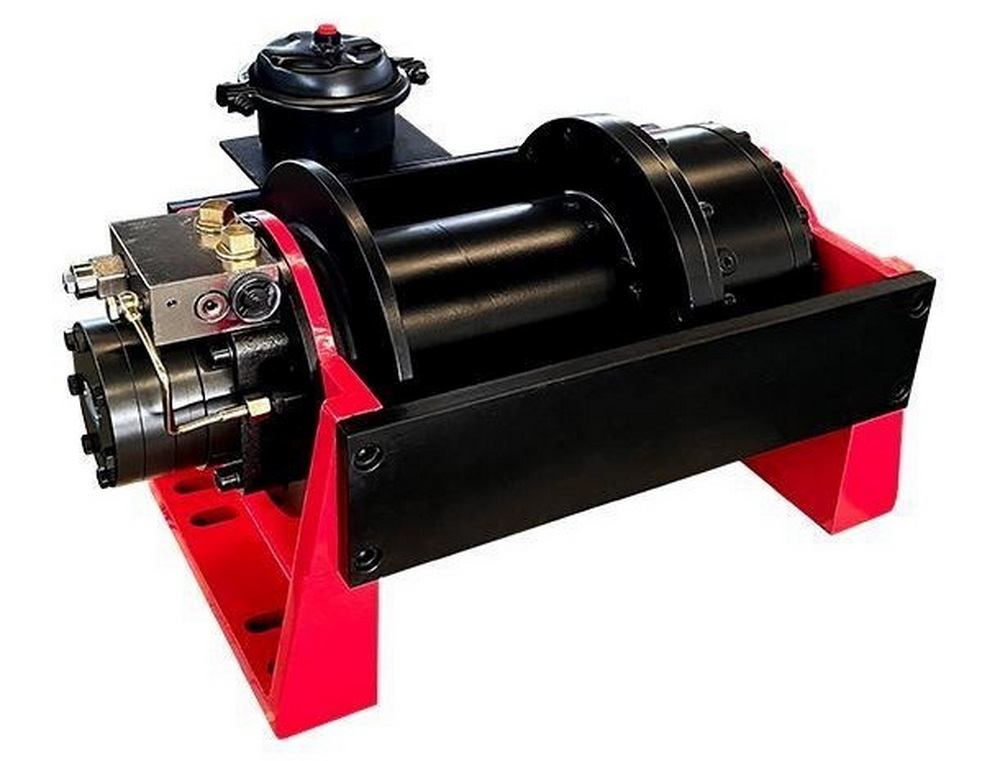

Ningbo Bonny is a manufacturer focusing on hydraulic motors, hydraulic winches, planetary gearboxes, and track undercarriages, which positions it among the integrated Planetary Winch Manufacturers in China. The combination of hydraulic motor, planetary gearbox, and tracked undercarriage is similar to Kemer's scope, making Bonny an alternative source for complete drive modules.

Its planetary winch and hydraulic motor product lines are often used in construction equipment, small cranes, and special vehicles. Having hydraulic motors and planetary winches from the same supplier can simplify warranty and spare parts management for OEM customers.

Jiangyin Zhongxin is listed as a manufacturer of hydraulic winches and other winch types, contributing to the group of Planetary Winch Manufacturers focusing on engineering equipment. Its hydraulic winches are used for construction hoisting, industrial pulling, and related engineering tasks that typically favor planetary gear drives for high torque in limited space.

The company carries multiple winch families, including electric and hydraulic variants, supporting end-users who want standardized winch interfaces but different power sources. For overseas buyers, this helps keep mounting and rope management consistent across machine upgrades.

Major B2B platforms list many Planetary Winch Manufacturers in China, offering hydraulic planetary winches, planetary gearboxes, and integrated winch drives for bulldozers, tractors, excavators, and trucks. These suppliers typically provide CE, ISO, or similar certifications and OEM/ODM support, enabling private-label planetary winch solutions for regional brands and equipment assemblers.

Such Planetary Winch Manufacturers often focus on flexible customization—adapting mounting flanges, drum length, rope capacity, and hydraulic motor displacement. This is especially useful for small or mid-size OEMs that need niche winch variants without building in‑house gearbox and motor expertise.

Beyond the named brands, there are further specialized Planetary Winch Manufacturers in China focusing on segments like marine capstan winches, deck winches, drilling winches, and vehicle recovery winches built around planetary gear drives. These manufacturers often emerge from marine equipment, gearbox, or hydraulic power pack backgrounds and progressively extend into planetary winch product lines for niche applications.

For buyers with very specific requirements—such as explosion‑proof environments, extreme temperatures, or offshore classification—these specialized Planetary Winch Manufacturers can be valuable partners, provided there is clear technical communication and validation testing. Close cooperation on design verification, FEA, and prototype testing is common for such high-spec projects.

Planetary winches rely on a planetary gearbox where a central sun gear drives multiple planet gears, which rotate within a ring gear to amplify torque in a compact structure. Among Planetary Winch Manufacturers, this design is popular because it delivers high torque density, smooth load sharing, and good efficiency for both continuous and intermittent duty cycles.

In a typical hydraulic planetary winch, a hydraulic motor drives the sun gear, the planetary carrier connects to the drum, and a multi-disc brake ensures safe load holding. Planetary Winch Manufacturers tune gear ratios, motor displacement, and brake capacity so the winch can start heavy loads smoothly, resist shock loads, and maintain stable speed under varying pressures.

Planetary Winch Manufacturers in China provide several advantages that are attractive to overseas OEMs, integrators, and distributors. These benefits extend beyond pricing and include technology, flexibility, and supply chain strengths.

- Wide product range from compact vehicle winches to heavy industrial and marine planetary winches.

- Strong capability to combine planetary gearboxes, hydraulic motors, and undercarriage or drive systems into complete packages.

- Competitive lead times thanks to industrial clusters and integrated machining and assembly lines.

- Customization options for mounting, rope capacity, braking, and control valves to match host equipment.

- Export experience and familiarity with global standards for documentation, labeling, and inspection.

Planetary Winch Manufacturers support a wide range of application scenarios where compactness, high torque, and controllable speed are essential. This versatility explains why planetary winch solutions appear in many sectors.

- Construction and lifting: truck cranes, crawler cranes, concrete pump trucks, aerial work platforms, and drilling rigs.

- Marine and offshore: anchor winches, mooring winches, towing winches, deck machinery, and capstan winches.

- Industrial and process plants: hoisting winches, conveyor take‑up winches, and maintenance lifting systems.

- Mining and tunneling: pulling winches, rail and belt system tensioning, and equipment recovery.

- Special vehicles: recovery trucks, logging vehicles, and defense or rescue applications.

When working with Planetary Winch Manufacturers in China, buyers can improve project outcomes by following structured sourcing practices. Clear technical communication and qualification of suppliers are especially important for critical lifting equipment.

- Define performance requirements precisely: rated pull, first-layer line speed, duty cycle, rope capacity, and mounting constraints.

- Ask Planetary Winch Manufacturers for drawings, performance curves, and detailed BOM to evaluate suitability.

- Verify testing and inspection procedures, including pressure tests, load tests, and brake holding tests.

- Review reference projects, especially with similar applications or in similar environments.

- Consider long-term support: spare parts lead times, documentation, and technical assistance availability.

Planetary Winch Manufacturers in China now offer a mature ecosystem of hydraulic and electric planetary winches, planetary gearboxes, and complete motion systems that can support demanding construction, marine, mining, and industrial applications. From integrated system specialists such as Kemer—combining tracked undercarriages, planetary winches, planetary gearboxes, travel drives, swing drives, and hydraulic motors—to marine-focused companies and heavy industrial winch producers, overseas buyers can match almost any line pull and duty cycle requirement with a suitable Chinese planetary winch solution.

For global OEMs and project contractors, the key to leveraging Planetary Winch Manufacturers in China is structured supplier evaluation, clear technical specifications, and close engineering collaboration during design and prototype stages. With these practices in place, planetary winch systems sourced from China can deliver high torque density, reliability, and cost-effectiveness across a wide variety of projects.

Chinese Planetary Winch Manufacturers provide a broad product range, integrating winches, planetary gearboxes, hydraulic motors, and related drivetrain components for many applications at competitive prices. Buyers also benefit from flexible customization, relatively short lead times, and accumulated export experience that simplifies documentation and logistics for overseas deliveries.

Planetary Winch Manufacturers typically design planetary gear stages with generous safety factors, use multi-disc brakes for secure load holding, and conduct pressure and load tests on each winch model. Many suppliers operate under ISO‑based quality systems and can provide material certificates, test reports, and inspection records for critical projects.

To obtain accurate proposals, buyers should specify required line pull, rope speed, rope capacity, drum dimensions, mounting interface, duty cycle, working environment, and hydraulic or electrical interface data. Planetary Winch Manufacturers will then select suitable gear ratios, motors, and brake sizes and return drawings, performance curves, and pricing for evaluation.

Many Planetary Winch Manufacturers in China can deliver complete systems, including winches, planetary gearboxes, hydraulic motors, power packs, and even undercarriages or other drivetrain components. This system-level capability allows OEMs to reduce engineering work, ensure mechanical compatibility, and consolidate after‑sales service with a smaller number of suppliers.

Kemer positions itself as a specialized manufacturer of tracked undercarriages, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors, serving global customers with integrated solutions. By focusing on planetary winch and drivetrain combinations, Kemer aims to help OEMs build compact, high-torque equipment with coordinated mechanical and hydraulic performance across the entire machine.