Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

>> Typical Applications of a Hydraulic Winch

● Key Components of a Hydraulic Winch

>> Control and Safety Elements

● Safety Preparations Before Using a Hydraulic Winch

>> Pre‑Use Inspection Checklist

>> Worksite and Operator Safety

● Step‑by‑Step Operation of a Hydraulic Winch

>> 2. Paying Out Rope (Line‑Out)

>> 3. Rigging and Attaching the Load

>> 4. Pulling the Load (Line‑In)

>> 5. Controlling Speed and Tension

>> 6. Stopping and Securing the Load

● Advanced Operating Tips for a Hydraulic Winch

>> Managing Long or Steep Pulls

>> Using a Hydraulic Winch in Marine Conditions

● Maintenance Best Practices for a Hydraulic Winch

>> Periodic Overhaul and Testing

● Training and Best Practices for Hydraulic Winch Operators

>> Operator Skills and Certification

● FAQ About Operating a Hydraulic Winch

>> Q1. What is the main advantage of a hydraulic winch over an electric winch?

>> Q2. How do I know if my load is too heavy for the hydraulic winch?

>> Q3. How often should I replace the rope on a hydraulic winch?

>> Q4. Can a hydraulic winch operate underwater or in marine environments?

>> Q5. What should I do if the hydraulic winch makes unusual noises during operation?

>> Q6. Is it safe to guide the rope by hand on a hydraulic winch?

>> Q7. How many wraps must remain on the drum of a hydraulic winch?

>> Q8. Can I use any hydraulic oil in my hydraulic winch system?

>> Q9. What environmental conditions affect hydraulic winch performance?

>> Q10. Do I need formal training to operate a hydraulic winch?

Operating a hydraulic winch correctly ensures safe, controlled handling of heavy loads in industrial, mobile, construction, towing, and marine applications. With proper procedures, a hydraulic winch offers powerful, continuous duty performance and long service life.[1][2]

A hydraulic winch is a pulling device driven by pressurized hydraulic oil rather than electric power, making it ideal for sustained, high‑torque work. Because hydraulic power is taken from an engine or central power pack, a hydraulic winch can run for long periods without overheating like some electric systems.[3][4][1]

A well‑designed hydraulic winch is widely used across different industries where reliable pulling and lifting are essential.[5][1]

- Vehicle recovery and towing operations that demand constant heavy pulling with a hydraulic winch.[6][1]

- Construction and foundation projects where a hydraulic winch handles formwork, pipes, or structural components.[2][3]

- Marine and offshore platforms using a hydraulic winch for mooring, anchoring, and deck handling tasks.[2][5]

- Forestry and agriculture equipment relying on a hydraulic winch for skidding logs or moving implements on steep terrain.[7][2]

Understanding the main parts helps operators use and maintain any hydraulic winch more effectively. Each element has a specific function in transmitting power and controlling load movement in the hydraulic winch system.[8][1][3][2]

These components convert hydraulic energy into pulling force for the hydraulic winch.[1][3]

- Hydraulic pump: Draws oil from the reservoir, pressurizes it, and supplies fluid power to the hydraulic winch motor.[3][1]

- Hydraulic motor: Converts pressure and flow into torque and rotation, driving the drum of the hydraulic winch.[1][3]

- Planetary gearbox or reducer: Increases torque and reduces speed so the hydraulic winch can pull heavy loads smoothly without stalling.[8][3]

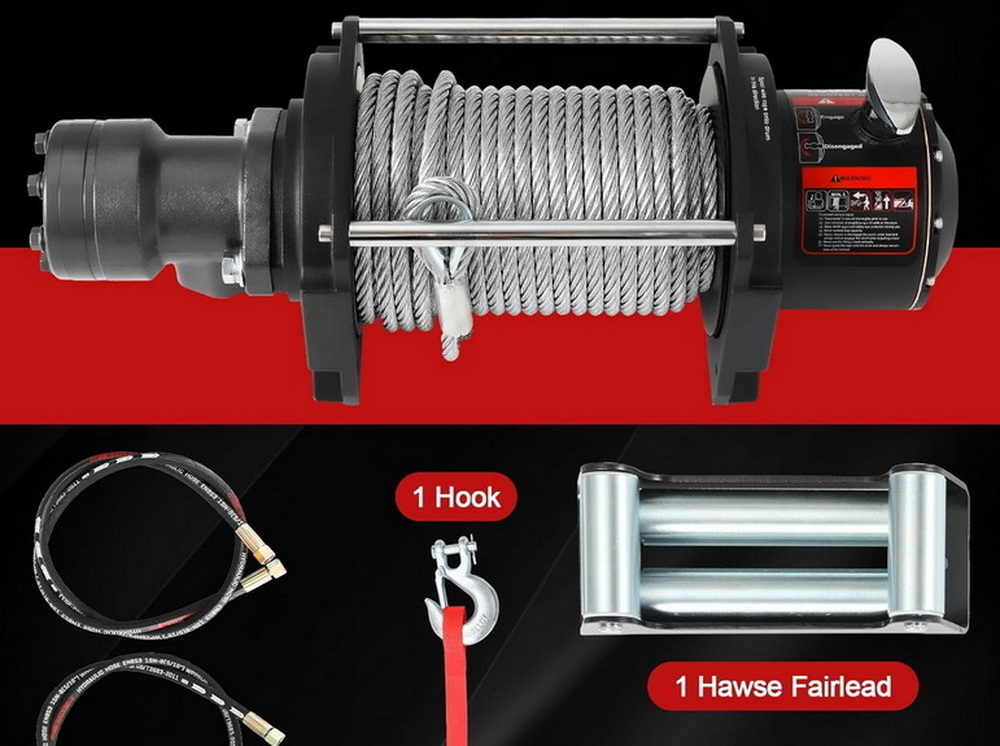

The visible working end of any hydraulic winch is the drum and the rope it carries.[9][8]

- Drum: Cylindrical shell that winds and unwinds rope while the hydraulic winch motor turns it through the gearbox.[3][8]

- Wire or synthetic rope: Transmits pulling force from the hydraulic winch drum to the load; selected and sized based on rated line pull.[10][9]

- Brake system: Automatically holds the drum when the control is neutral, preventing unintended load movement on the hydraulic winch.[2][8]

Control components allow operators to modulate force, direction, and speed on the hydraulic winch.[8][2]

- Control valve and levers: Direct oil flow for line‑in, line‑out, or neutral positions of the hydraulic winch.[1][8]

- Relief valves: Limit system pressure to protect hoses, pump, and hydraulic winch motor from overload.[11][9]

- Hoses, fittings, and reservoir: Form the closed loop that delivers, returns, and cools hydraulic oil for the winch system.[3][1]

- Mounting frame and structure: Secure the hydraulic winch to a chassis, deck, or base frame to safely transfer pulling forces.[4][9]

A hydraulic winch works by channeling pressurized oil to a motor that rotates the drum through a reduction gearbox. By adjusting flow and pressure, the operator can regulate drum speed and pulling force of the hydraulic winch.[2][1][3]

Although configurations vary, most hydraulic winch systems follow a similar principle.[1][3]

- The pump sends pressurized oil to the control valve whenever the engine or power pack runs.[3][1]

- The operator moves the valve handle to direct oil into one side of the motor for line‑in or the opposite side for line‑out on the hydraulic winch.[8][1]

- The hydraulic motor drives the gearbox and drum, winding or unwinding rope from the hydraulic winch.[8][3]

- When the control returns to neutral, oil flow stops and the brake holds the drum, keeping the hydraulic winch and load still.[2][8]

Safe hydraulic winch operation begins long before the drum moves. Proper inspections and worksite setup dramatically reduce risk.[6][9][10]

A fast but thorough inspection should precede every hydraulic winch job.[9][2]

- Examine the hydraulic winch frame, drum, and mounting for cracks, rust, and loose bolts.[6][9]

- Check hydraulic hoses for leaks, bulges, rubbing, or twisted routing around the hydraulic winch.[9][6]

- Verify oil level, cleanliness, and specified viscosity for the hydraulic winch system.[2][3]

- Inspect rope for broken strands, corrosion, flat spots, and kinks, especially near terminations on the drum of the hydraulic winch.[10][9]

- Confirm labels and safety decals for capacity, pressure, and rotation directions on the hydraulic winch are readable.[4][9]

Even a perfectly maintained hydraulic winch can be dangerous if the worksite is not controlled.[10][9]

- Establish an exclusion zone where no one stands in line with the rope or under suspended loads from the hydraulic winch.[9][10]

- Remove trip hazards and sharp edges that might cut the rope driven by the hydraulic winch.[11][9]

- Agree on radio or hand signals before starting; confusion around a hydraulic winch can cause serious accidents.[5][9]

- Wear gloves, helmet, eye protection, and sturdy footwear whenever working near the hydraulic winch.[10][9]

The following procedure shows a typical way to operate a hydraulic winch safely and efficiently. Always adapt steps to the individual machine's manual and local regulations.[4][8][2]

The goal of startup is to energize the hydraulic winch without unintended drum rotation.[1][2]

- Start the engine or power pack that supplies hydraulic power and let it reach operating temperature.[3][2]

- Engage the PTO or open the supply valve that connects pump flow to the hydraulic winch circuit.[8][2]

- Keep the winch control in neutral while monitoring pressure gauges to confirm normal operating pressure.[2][8]

Controlled payout keeps the hydraulic winch rope neat and prevents damage.[9][8]

- Move the control to the line‑out position to unwind rope from the hydraulic winch slowly.[8][2]

- Maintain light tension so coils do not loosen or tangle on the hydraulic winch drum.[9][8]

- Avoid pulling rope by hand while the hydraulic winch is powered; let the drum and controls do the work.[10][9]

Good rigging practice is essential no matter how strong a hydraulic winch may be.[11][9]

- Use shackles, hooks, and slings rated equal to or above the hydraulic winch line pull.[4][11]

- Anchor to stable points like towing eyes, structural beams, or ground anchors suited to the hydraulic winch load.[5][2]

- Keep the rope as straight as possible so the hydraulic winch does not experience extreme side pull.[5][8]

During line‑in, operators must continuously monitor the hydraulic winch, rope, and surroundings.[2][8]

- Move the control smoothly to line‑in and start at a low speed while the hydraulic winch takes up slack.[8][2]

- Increase speed gradually while ensuring the load moves predictably and the rope winds in tight, even layers on the hydraulic winch drum.[9][2]

- Stop immediately if the hydraulic winch stalls, jerks violently, or causes the rope to crush or cross‑wrap.[6][9]

Efficient hydraulic winch use is about control, not maximum speed.[9][2]

- Use proportional control (if equipped) to fine‑tune drum speed on the hydraulic winch based on operator input.[1][2]

- Keep the line as straight as possible; side‑loading increases tension and wear on the hydraulic winch drum flanges.[2][8]

- Avoid sudden reversals between line‑in and line‑out with the hydraulic winch, which can shock gears and mounting points.[11][9]

Safe stopping prevents creep or unintended motion after hydraulic winch use.[8][2]

- Return the control handle to neutral so the hydraulic winch stops and the brake engages.[2][8]

- Ensure the load is supported by ground, chocks, or structural supports before approaching the hydraulic winch or rigging.[10][9]

- Only remove hooks, shackles, or chokers once the rope from the hydraulic winch is completely slack.[11][9]

Proper shutdown protects the hydraulic winch and hydraulic circuit for future work.[9][2]

- Place all controls in neutral and confirm the drum on the hydraulic winch is fully stopped.[8][2]

- Disengage PTO or close the hydraulic supply valve leading to the hydraulic winch.[2][8]

- Let the engine idle briefly to equalize temperatures, then shut down and perform a quick post‑use check on the hydraulic winch.[3][2]

Once basic skills are in place, operators can refine technique to maximize productivity with a hydraulic winch.[4][2]

Demanding terrain and long cable lengths require extra care with a hydraulic winch.[5][1]

- Use snatch blocks to change direction and effectively multiply pulling capacity of the hydraulic winch when needed.[11][9]

- Allow cooling pauses during very long pulls so oil temperature around the hydraulic winch remains within the recommended range.[3][2]

- Re‑spool rope neatly after each long pull to maintain safe layering on the hydraulic winch drum.[9][8]

Marine environments expose a hydraulic winch to salt, spray, and constant moisture.[5][2]

- Choose corrosion‑resistant materials, coatings, and ropes specified for marine hydraulic winch applications.[5][2]

- Rinse the hydraulic winch with fresh water after saltwater exposure and follow aggressive anti‑corrosion maintenance schedules.[5][2]

- Regularly inspect seals and bearings because water ingress can quickly damage a marine hydraulic winch.[3][2]

Preventive maintenance is the most cost‑effective way to keep a hydraulic winch safe and reliable.[3][2]

Short, frequent checks help detect problems early on any hydraulic winch.[4][2]

- Verify oil level and check for discoloration or foaming that might indicate contamination in the hydraulic winch system.[3][2]

- Inspect hoses, fittings, and seals on and around the hydraulic winch for fresh leaks after each shift.[6][9]

- Look at rope condition and drum spooling every day, especially when the hydraulic winch has been used near its capacity.[10][9]

Over time, wear accumulates even on robust hydraulic winch systems.[2][3]

- Perform scheduled flow and pressure tests to confirm the pump, valves, and motor still meet design performance for the hydraulic winch.[3][2]

- Replace high‑wear components like seals, bearings, and hoses before failure, based on service hours of the hydraulic winch.[6][9]

- Record all repairs and measurements in maintenance logs tied to the serial number of the hydraulic winch.[4][2]

Training is just as critical as hardware quality in any hydraulic winch application.[10][9]

Proper training ensures that each hydraulic winch is used within its design limits.[10][9]

- Ensure operators can read load charts and understand line pull ratings for each hydraulic winch in the fleet.[4][9]

- Provide hands‑on instruction in rigging, signaling, and emergency stop procedures involving the hydraulic winch.[10][9]

- Refresh training regularly, particularly when procedures or hydraulic winch models change.[11][9]

Every crew needs clear responses to unexpected events involving a hydraulic winch.[9][10]

- Establish a simple command to stop the hydraulic winch immediately if anyone notices a hazard.[10][9]

- Teach personnel to recognize early warning signs, such as rope damage, overheating, or unusual vibration of the hydraulic winch.[6][2]

- Make sure emergency isolation valves and controls for the hydraulic winch are clearly marked and unobstructed.[6][9]

A well‑operated hydraulic winch is a powerful, reliable tool for demanding lifting and pulling work in industrial, mobile, and marine environments. By understanding components, following structured operating steps, applying strong safety discipline, and performing consistent maintenance, operators can maximize performance and extend the life of every hydraulic winch in their fleet.[1][5][9][2]

The primary advantage is continuous duty performance: a hydraulic winch can run longer under heavy load without overheating, as engine‑driven hydraulic power is more tolerant of sustained use. This makes a hydraulic winch ideal for towing, construction, and marine tasks where pulls are long and frequent.[1][4][3]

Check the rated line pull on the nameplate or in the manual and compare it with your calculated load, including angles and friction. If the hydraulic winch slows dramatically, stalls, or causes system pressure to spike near the relief setting, the load is likely excessive and the setup must be changed.[4][9][2]

Rope on a hydraulic winch should be replaced whenever inspection shows broken wires, severe corrosion, kinks, or damage beyond allowable limits in the applicable standard or manual. High‑use or harsh‑environment hydraulic winch systems may require more frequent replacement intervals than light‑duty units.[9][10]

Many models are specifically designed for marine conditions, with sealed motors, special coatings, and corrosion‑resistant materials throughout the hydraulic winch assembly. Always confirm that the specific hydraulic winch is rated for submerged or splash‑zone operation before deploying it offshore or onboard a vessel.[5][1][2]

Unusual grinding, knocking, or whining sounds from a hydraulic winch may indicate cavitation, bearing damage, or gearbox issues. Stop operation, isolate power, and have a qualified technician inspect the hydraulic winch and hydraulic circuit before using it again.[6][2][9]

Guiding rope by hand near the drum or fairlead of a hydraulic winch is unsafe because fingers, clothing, or tools can be pulled into rotating parts. Use approved guiding tools or mechanical fairlead systems and always keep hands well clear of the hydraulic winch under load.[10][9]

Most manuals require at least five full wraps of rope to stay on the hydraulic winch drum at maximum extension to maintain safe anchorage. Operating a hydraulic winch with too few wraps can cause rope slippage or separation from the drum under high tension.[12][8][2]

Using the wrong oil grade can cause overheating, sluggish response, or wear in the hydraulic winch motor and valves. Always use the viscosity and specification recommended by the manufacturer for that particular hydraulic winch and its climate range.[4][2][3]

Extreme heat, cold, moisture, dust, and corrosive atmospheres all influence oil viscosity, seal life, and corrosion on a hydraulic winch. Selecting suitable materials, filters, and service intervals helps keep the hydraulic winch reliable in harsh field conditions.[5][2][3]

Formal instruction is strongly recommended because misuse of a hydraulic winch can cause severe injury or equipment damage. Many companies and manufacturers offer structured training, which covers controls, rigging, and emergency procedures specific to each hydraulic winch model.[11][9][10]

[1](https://garlway.com/faqs/how-does-a-hydraulic-winch-operate)

[2](https://chiefengineerlog.com/2023/09/02/marine-hydraulic-winches-operation-maintenance-and-troubleshooting/)

[3](https://www.ini-hydraulic.com/news/how-hydraulic-winches-work-and-their-applications)

[4](https://pennyengineering.com/wp-content/uploads/2021/02/PH-Winch-Guide.pdf%3Fsrsltid=AfmBOoo0FSpNnCBvOX7r3AcPdvGtB3enIT4_G5LaABTE3iA1jlYDVdvW)

[5](https://www.zavamarine.com/key-considerations-of-operating-a-marine-hydraulic-winch/)

[6](https://legendhire.com.au/are-winches-dangerous/)

[7](https://www.youtube.com/watch%3Fv=MAjqWKS1Ku4)

[8](https://www.alliedsystems.com/pdf/Winch/Manuals/599043W.pdf)

[9](https://www.heswinches.com.au/pub/media/winches/brochures/Winch_Safety_Guide_Rev-1.2.pdf)

[10](https://www.winchhire.co.uk/the-ultimate-guide-to-the-dos-and-donts-of-winch-safety/)

[11](https://saivs-industrial.com/blog/Hydraulic-Winch-FAQs-for-Safe-and-Secure-Operation/)

[12](https://toracompany.com/wp-content/uploads/2023/03/hydraulic-Winch-User-manual.pdf)

Top Rubber Track Undercarriage Manufacturers And Suppliers in Russia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Indonesia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Australia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Brazil

Top Track Undercarriage Manufacturers And Suppliers in Hungary

Top Track Undercarriage Manufacturers And Suppliers in Greece

Top Track Undercarriage Manufacturers And Suppliers in Luxembourg

Top Track Undercarriage Manufacturers And Suppliers in Lithuania