Views: 222 Author: Robert Publish Time: 2026-01-16 Origin: Site

Content Menu

● Understanding Track Undercarriage Systems

● European and Luxembourg Market Context

● Core Components Provided by Track Undercarriage Manufacturers and Suppliers

● Kemer: Specialist Manufacturer for Crawler Undercarriages and Hydraulic Drives

● How Kemer Supports Luxembourg and the Benelux Region

● Criteria for Selecting Track Undercarriage Manufacturers and Suppliers in Luxembourg

>> Load capacity and duty cycle

>> Material quality and manufacturing processes

>> Logistics and delivery into Luxembourg

>> After‑sales service and parts support

● Importance of Hydraulic Drives, Winches, and Planetary Gearboxes

● Sustainability and Lifecycle Value in the European Context

● Practical Cooperation Models for Luxembourg Buyers

● FAQ

>> 3. Why is integration of hydraulic winches and planetary gearboxes important for tracked equipment?

>> 4. What maintenance practices can extend undercarriage life in European climates?

>> 5. How can Kemer cooperate with local Track Undercarriage Manufacturers and Suppliers in Luxembourg?

Luxembourg is a compact but strategically positioned market at the heart of Europe, surrounded by powerful industrial economies that heavily rely on tracked machinery and advanced crawler systems. As infrastructure, logistics, tunneling, and energy projects evolve, demand grows for reliable Track Undercarriage Manufacturers and Suppliers capable of supporting both original equipment manufacturers (OEMs) and specialist integrators.

This article explores how the European undercarriage ecosystem serves Luxembourg, what to look for in Track Undercarriage Manufacturers and Suppliers, and how Kemer can act as a key partner by offering integrated crawler undercarriages, hydraulic winches, planetary gearboxes, and related drive solutions.

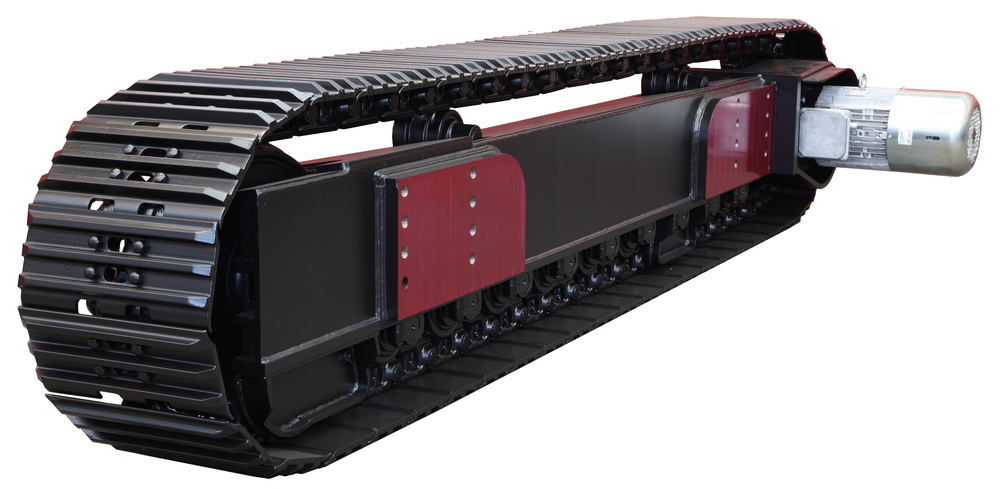

A track undercarriage is the structural and mechanical foundation that allows tracked machines such as excavators, bulldozers, drilling rigs, pavers, and special industrial platforms to move safely and efficiently over challenging ground conditions. It typically includes a welded or cast frame, track chains, rollers, idlers, sprockets, track shoes or rubber tracks, and tensioning mechanisms that keep the system aligned and under controlled preload.

Track Undercarriage Manufacturers and Suppliers design these assemblies to spread the machine's weight over a larger surface area than wheeled vehicles, reducing ground pressure and improving traction on soft, muddy, rocky, or uneven terrain. When correctly specified, the undercarriage helps stabilize the load, protect the superstructure, and maintain productivity over thousands of operating hours.

In practice, the undercarriage is one of the highest wear cost centers of a tracked machine. A well‑engineered system can significantly reduce total cost of ownership by extending component life, simplifying maintenance, and avoiding catastrophic failures that take a machine out of service unexpectedly. This is why end‑users in Luxembourg pay close attention to the capabilities of Track Undercarriage Manufacturers and Suppliers that support their fleets.

While Luxembourg itself has a smaller domestic manufacturing base for heavy equipment, it sits inside a dense industrial corridor that includes Germany, France, Belgium, and the Netherlands. These neighboring countries host major construction equipment OEMs, regional distributors, and aftermarket specialists that collectively act as the primary Track Undercarriage Manufacturers and Suppliers for the Benelux region.

Studies of the global and European undercarriage components and systems markets show steady growth driven by infrastructure modernization, road expansion, mining activity, and urban development across the continent. As tracked machinery remains critical for earthworks, foundations, tunneling, pipelines, renewable energy installations, and heavy logistics, the demand for chains, rollers, sprockets, shoes, and complete crawler bases continues to expand.

For buyers in Luxembourg, this means easy access to a wide pool of Track Undercarriage Manufacturers and Suppliers, including specialized Benelux distributors, pan‑European undercarriage brands, and global manufacturers exporting crawler frames and components into the region. Timely logistics, cross‑border service, and multilingual technical support are standard expectations.

Most Track Undercarriage Manufacturers and Suppliers active in Europe and serving Luxembourg offer a broad portfolio of parts and assemblies so that clients can source a complete undercarriage from a single partner. Typical categories include:

- Track chains and link assemblies

Hardened steel links with pins and bushings, available in sealed or sealed‑and‑lubricated (SALT) versions, designed for excavators, dozers, and other tracked machines. Correct chain pitch and bushing hardness are critical to resisting elongation and maintaining proper engagement with sprockets.

- Bottom rollers and carrier (top) rollers

These components support the weight of the machine and the track chain, absorbing impact and guiding the track path along the undercarriage frame. High‑quality rollers use optimized sealing systems and controlled surface hardening to resist wear and contamination.

- Idlers and tensioning systems

Front idlers help maintain track alignment and, together with recoil springs or hydraulic adjusters, keep the track properly tensioned. Well‑designed Track Undercarriage Manufacturers and Suppliers pay attention to idler profile, bearing life, and adjuster design to prevent derailment and uneven wear.

- Sprockets and segments

Sprockets transmit torque from the final drive or planetary gearbox to the chain. Precisely machined teeth and correct hardness profiles reduce wear and ensure smooth power transfer. Modular segments are often used for easier replacement in the field.

- Steel track shoes and rubber tracks

Steel shoes are used for heavy machines and tough conditions, available in different widths and grousers for multiple traction and flotation levels. Rubber tracks are common on compact track loaders, mini excavators, and light platforms where ground protection and low vibration are priorities.

Many advanced Track Undercarriage Manufacturers and Suppliers combine these mechanical elements with improved metallurgy, induction hardening, shot peening, and controlled heat treatment sequences. Some also experiment with smart features such as embedded wear indicators or telematics‑ready sensors that support predictive maintenance programs.

Ningbo Kemer Engineering Machinery Co., Ltd. is a specialized manufacturer that has positioned itself as a comprehensive supplier of crawler undercarriages and hydraulic drive components. Established in 2012 in China's Ningbo Economic & Technical Development Zone, Kemer focuses on research, manufacturing, and sales of steel and rubber tracked undercarriage assemblies and related transmission products.

Kemer's product range covers:

- Steel tracked undercarriages with load capacities roughly from a few tons up to tens of tons, suited for medium and heavy engineering machinery.

- Rubber tracked undercarriages for smaller loads, commonly deployed on compact, mobile or light‑duty applications where surface protection and low noise are important.

- Hydraulic winches that provide high pulling forces for drilling rigs, lifting systems, and recovery tasks.

- Planetary gearboxes, including travel drives, swing drives, and winch drives, offering compact yet high‑torque solutions for mobile machinery.

- Hydraulic motors and integrated drive units that interface directly with the undercarriage to deliver smooth travel and rotation control.

Kemer emphasizes flexible engineering and can tailor key parameters such as track shoe width, overall length and width of the undercarriage, mounting interfaces, reduction ratios, and torque outputs. This level of customization allows equipment manufacturers and system integrators to optimize machine stability, clearance, and manoeuvrability while using standardized Track Undercarriage Manufacturers and Suppliers components.

Even though Kemer's production facilities are in China, its crawler track undercarriages and hydraulic drive components are widely present in international markets through export‑oriented distribution and B2B platforms. European buyers, including those in Luxembourg and neighboring Benelux countries, can source Kemer products either directly or via regional partners who handle final integration, assembly, and service.

Kemer's undercarriage offerings are well suited to:

- Drilling and piling rigs used on construction and geotechnical projects.

- Concrete pumps and mobile industrial equipment that require stable tracked travel.

- Utility, maintenance, and inspection platforms operating on difficult terrain.

- Agricultural and forestry machinery that benefit from compact tracked solutions.

By selecting a Kemer crawler base and combining it with local structures, booms, masts, and control systems, engineers in Luxembourg can create machines that meet European standards while benefiting from competitive manufacturing costs. This hybrid approach allows local Track Undercarriage Manufacturers and Suppliers, integrators, and OEMs to focus on application‑specific design, while Kemer supplies the core traction and winch power modules.

When choosing Track Undercarriage Manufacturers and Suppliers to support projects in Luxembourg, buyers should evaluate both technical and commercial competencies. Some key criteria include:

The undercarriage must be sized for the machine's operating weight, attachments, and expected working conditions. For example, drilling rigs with heavy masts and variable loads require undercarriages that can manage both static and dynamic stresses without excessive deformation or premature wear. Clear communication of duty cycle, terrain type, and slope conditions is crucial.

Reputable Track Undercarriage Manufacturers and Suppliers use high‑strength steels, carefully controlled casting and forging operations, and repeatable welding procedures. They also apply advanced heat treatments to achieve the right combination of surface hardness and core toughness. ISO‑certified management systems and traceability of materials are strong indicators of quality.

Many projects in Luxembourg involve constrained urban sites, tunnels, industrial plants, or energy facilities where standard undercarriage dimensions may not fit. Strong partners can design non‑standard track gauges, frame shapes, bolt patterns, and drive configurations. Kemer is an example of a manufacturer that actively supports this type of custom engineering to meet specific working envelope requirements.

Despite Luxembourg's small size, its high project density and cross‑border mobility demand short lead times and reliable deliveries. Buyers should verify whether Track Undercarriage Manufacturers and Suppliers have regional warehouses, efficient shipping routes, or long‑term agreements with freight partners that can move heavy components quickly and economically throughout the Benelux corridor.

Even the best undercarriage will eventually wear. A structured spare‑parts strategy and responsive technical support are essential. Buyers should prioritize suppliers with:

- Stock of common wear parts (rollers, sprockets, chains, rubber tracks) in or near the Benelux region.

- Clear documentation of inspection intervals, torque specifications, and replacement procedures.

- Ability to provide failure analysis and improvement suggestions when abnormal wear is detected.

Modern tracked machines are not just about mechanical robustness; they also depend heavily on efficient hydraulic and mechanical power transmission. Travel drives, swing drives, and winch drives convert hydraulic energy into controlled movement of the undercarriage and attached equipment, making them an integral part of what Track Undercarriage Manufacturers and Suppliers ultimately deliver.

Kemer's range of hydraulic motors and planetary gearboxes is designed to integrate directly with crawler frames. By using compact planetary stages with high reduction ratios, Kemer's drives:

- Deliver high torque at low speeds, ideal for climbing slopes, working in confined spaces, or handling heavy pulling tasks.

- Maintain smooth movement and precise control, which is essential in applications like drilling, lifting, and precision positioning.

- Help minimize external piping and mounting complexity by offering integrated flanges, output shafts, and sealing arrangements matched to the undercarriage layout.

For winching operations, Kemer hydraulic winches combined with planetary gearboxes provide controlled pulling power for pipeline projects, slope stabilization, forestry operations, and rescue applications. When paired with robust crawler undercarriages, this creates a unified solution that Track Undercarriage Manufacturers and Suppliers can promote to high‑end customers in Luxembourg who require both mobility and controlled force.

Sustainability is gaining prominence in Europe's construction and industrial sectors, and undercarriage systems are part of this trend. European regulations and climate targets push companies to extend machine life, reduce material waste, and improve energy efficiency throughout the equipment lifecycle.

Track Undercarriage Manufacturers and Suppliers are responding with several strategies, including:

- Designing longer‑lasting components that reduce the frequency of replacements and the associated environmental impact.

- Exploring eco‑friendlier materials and surface treatments that offer high wear resistance while minimizing harmful substances.

- Supporting remanufacturing and refurbishment programs, where rollers, idlers, and tracks are rebuilt instead of scrapped.

- Optimizing undercarriage designs to reduce overall machine weight without compromising load capacity, which can contribute to fuel savings and lower emissions.

Luxembourg‑based users benefit from these innovations by accessing undercarriage solutions that not only reduce operating costs but also align with their clients' environmental expectations and ESG reporting requirements.

To maximize value when working with Track Undercarriage Manufacturers and Suppliers, organizations in Luxembourg can adopt collaborative cooperation models rather than purely transactional purchasing. Practical steps include:

- Early engineering involvement

Engage suppliers during the concept and design phase to leverage their experience with chain pitch, shoe selection, frame geometry, and drive sizing. This reduces the risk of costly redesigns later in the project.

- Shared digital models

Exchange 3D CAD models and detailed mounting interfaces so that crawler frames, drives, and support brackets align perfectly with the machine structure. This improves assembly efficiency and service access.

- Lifecycle cost analysis

Compare options not only on purchase price but also on estimated wear rates, maintenance intervals, and downtime risk. Advanced Track Undercarriage Manufacturers and Suppliers can provide data or examples that help quantify total cost of ownership.

- Local integration with global sourcing

Combine imported crawler bases and drive components from manufacturers such as Kemer with local fabrication, assembly, and control systems. This hybrid model leverages global cost advantages while supporting local jobs and fast service.

Track Undercarriage Manufacturers and Suppliers serving Luxembourg operate within a broader European ecosystem that emphasizes quality, durability, and lifecycle efficiency for tracked machinery. By providing carefully engineered chains, rollers, sprockets, shoes, and complete crawler frames, these suppliers underpin the performance of excavators, drilling rigs, industrial platforms, and many other machines used in construction, mining, logistics, and energy projects.

Kemer has emerged as a flexible global partner in this field, delivering crawler track undercarriages, hydraulic winches, planetary gearboxes, travel drives, swing drives, and hydraulic motors that can be customized to diverse applications. For buyers and equipment manufacturers in Luxembourg, collaborating closely with such Track Undercarriage Manufacturers and Suppliers, defining requirements clearly, and evaluating lifecycle value rather than only purchase price are key steps to building reliable, competitive machinery for demanding European environments.

Heavy‑duty crawler systems are usually defined by higher permissible load capacities, robust welded or cast frames, thicker track shoes, and upgraded rollers, idlers, and sprockets designed to withstand severe impact and abrasive conditions. They often incorporate improved sealing, higher hardness levels, and extended service intervals to cope with continuous or high‑load operation in mining, quarrying, demolition, or heavy civil engineering works.

Yes. Many Track Undercarriage Manufacturers and Suppliers, including Kemer, offer customized track gauges, overall frame lengths, mounting patterns, and shoe widths to match specific machine designs. By providing detailed load data, duty cycles, and dimensional requirements, Luxembourg‑based OEMs and integrators can work with these manufacturers to develop crawler systems that fit constrained job sites while still using standardized wear parts to simplify future maintenance.

Integrating hydraulic winches and planetary gearboxes into the undercarriage design allows machines to deliver high pulling forces and controlled travel speeds without requiring oversized engines or complex mechanical transmissions. Planetary gearboxes provide high torque in a compact envelope, while hydraulic winches enable secure lifting, holding, and pulling operations. When these elements are engineered together with the crawler frame, the result is a balanced, efficient system that improves operator control, safety, and productivity.

To extend undercarriage life in Luxembourg and across Europe, operators should regularly clean mud, snow, and stones from chains and rollers, keep track tension within the recommended range, and routinely inspect rollers, idlers, and sprockets for uneven wear. Replacing worn components in sets, monitoring bushing wear, and using OEM‑grade lubricants and seals will reduce the risk of sudden failures. Training machine operators to avoid unnecessary high‑speed turns or excessive side‑loading also contributes significantly to longer undercarriage service life.

Kemer can supply complete steel or rubber tracked undercarriages, hydraulic winches, travel drives, swing drives, and planetary gearboxes, while local partners in Luxembourg and the Benelux region provide structural fabrication, electrical systems, control integration, and on‑site service. This division of roles allows local Track Undercarriage Manufacturers and Suppliers to focus on application‑specific engineering, compliance with European standards, and quick response to customer needs, while leveraging Kemer's high‑volume manufacturing capacity and specialized know‑how in crawler and hydraulic drive technology.

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey