Views: 222 Author: Robert Publish Time: 2026-01-17 Origin: Site

Content Menu

● Core Components Inside A Hydraulic Winch

>> Planetary Gearbox And Winch Drives

>> Brake System And Safety Functions

>> Drum, Clutch, And Support Structure

● Hydraulic Circuits In Winch Systems

● Advantages Of Hydraulic Winch Technology

● Industrial Applications Of Hydraulic Winches

>> Marine And Offshore Operations

>> Construction, Mining, And Infrastructure

>> Recovery, Utility, And Off‑Road Vehicles

>> Oil, Gas, And Energy Sectors

● Design Trends And Future Technologies

>> 1. What is a hydraulic winch?

>> 2. How does a hydraulic winch differ from an electric winch?

>> 3. Where are hydraulic winches commonly used?

>> 4. What maintenance does a hydraulic winch require?

>> 5. How do I size a hydraulic winch for my application?

Hydraulic winch technology combines fluid power, high‑torque hydraulic motors, planetary gearboxes, and robust brake systems to pull and lift very heavy loads with precise control. Compared with electric units, a hydraulic winch offers higher duty cycle, smoother operation under shock loads, and better reliability in harsh industrial and marine environments.

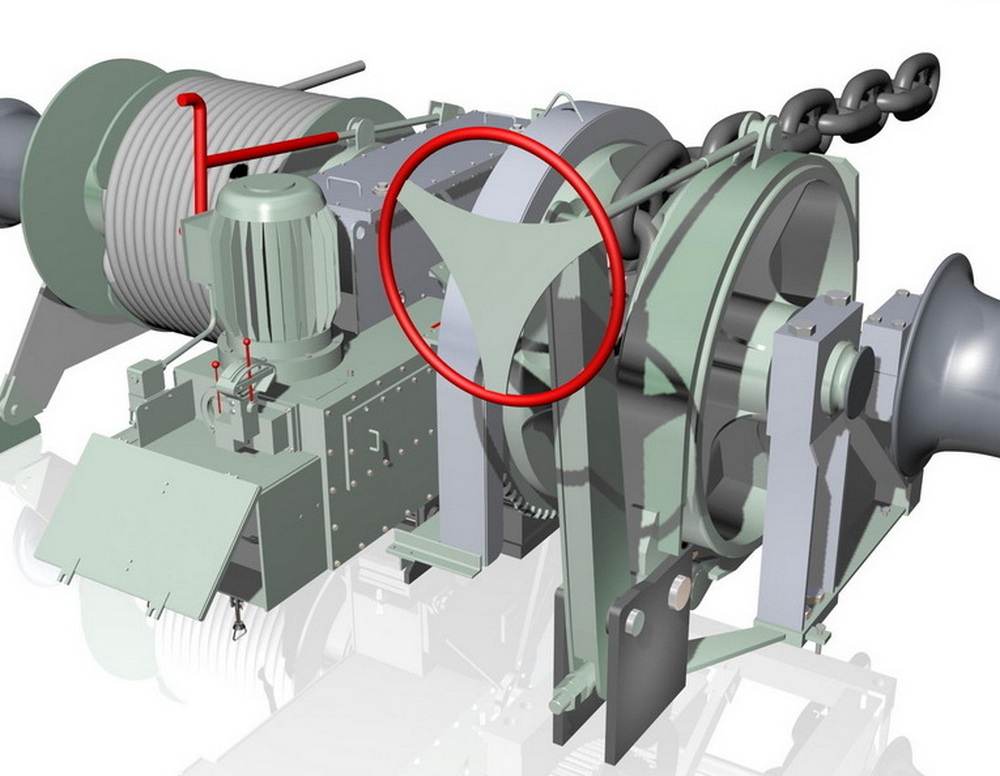

A hydraulic winch converts hydraulic energy into controlled rotational power at the winch drum, allowing rope or wire to be spooled in and out under high load. A typical hydraulic winch integrates a hydraulic pump, control valves, hydraulic motor, planetary gearbox, brake, clutch, support shaft, and drum into one compact, heavy‑duty package.

Hydraulic winch systems are based on classic fluid power principles, where pressure applied to a confined fluid is transmitted in all directions and transformed into powerful mechanical force at the motor and gears. In a hydraulic winch, this pressurized fluid is routed through hoses and valves to a hydraulic motor, which converts the fluid's energy into torque that spins the winch drum to move the load.

When the hydraulic pump is activated, it draws low‑pressure oil from a reservoir and increases its pressure using mechanical input from an engine, PTO, or power pack. Directional control valves then send this high‑pressure oil to either side of the hydraulic motor to rotate it in forward or reverse, enabling the hydraulic winch to pull in or pay out line as required.

To keep operation safe, the hydraulic circuit includes components such as pressure relief valves to prevent over‑pressurization and protect the hydraulic winch components. Return lines route oil back to the tank, creating a closed or semi‑closed loop that allows continuous duty for the hydraulic winch while managing heat more effectively than most electric systems.

For applications with variable load profiles, many hydraulic winch systems use a combination of fixed‑displacement and variable‑displacement pumps. This allows the hydraulic winch to deliver slow, high‑torque pull during heavy lifts and faster line speed under lighter loads, without changing the core mechanical design.

A modern hydraulic winch is an integrated mechanical‑hydraulic assembly in which each component is optimized for long service life, high load capacity, and safe operation. Understanding these components helps engineers, buyers, and operators specify and use the right hydraulic winch for demanding projects.

The hydraulic pump is the primary power source of the hydraulic winch, turning mechanical energy into pressurized fluid energy. In vehicle‑mounted hydraulic winches, the pump is often a power steering pump or dedicated hydraulic pump driven by the engine. In industrial or marine settings, pumps are usually driven by diesel engines or electric motors in central power packs.

Control valves regulate flow, pressure, and direction of the fluid to the hydraulic motor, directly setting the speed and direction of the hydraulic winch drum. Valve banks can include:

- Directional control valves for forward, neutral, and reverse.

- Flow control valves to limit or fine‑tune line speed.

- Pressure relief valves to protect against overload.

- Load‑holding or counterbalance valves to stabilize suspended loads.

These valves allow precise modulation of the hydraulic winch, so operators can feather the control lever, creep a load into place, or accelerate line speed when there is less tension.

The hydraulic motor is the heart of the hydraulic winch drive, converting fluid power into rotational torque. High‑torque, low‑speed motors are common, because they give the hydraulic winch strong starting torque and efficient pulling at low speeds without requiring oversized gear reductions.

By adjusting system pressure and flow, the hydraulic motor output can be tuned to deliver the required torque and drum speed. In many hydraulic winch designs, the motor shaft couples directly to the input of the planetary gearbox, ensuring smooth transfer of torque even under shock loads or near stall conditions.

For heavy‑duty applications, the hydraulic winch motor must withstand high internal pressures, repeated reversals, and continuous duty without overheating. Proper filtration and clean hydraulic fluid are critical to reduce wear on internal components such as gears, vanes, or pistons inside the motor.

Planetary gearboxes multiply the torque from the hydraulic motor while reducing speed, allowing a compact hydraulic winch to pull extremely heavy loads. Multi‑stage planetary designs (two‑stage or three‑stage) are common for industrial and marine winches, providing high gear ratios and smooth power transmission.

Planetary winch drives consist of a sun gear, planet gears, carrier, and ring gear, all enclosed in a robust housing. This configuration spreads torque across multiple gear meshes, increasing load‑carrying capacity and efficiency. Because of their compact form and excellent power density, planetary drives are widely used in:

- Construction and foundation rigs.

- Marine and offshore winch systems.

- Mining and energy sector hoisting equipment.

- Vehicle recovery and towing hydraulic winch systems.

Torque ratings for planetary winch drives can span from relatively small units for service vehicles to very large drives for offshore cranes and anchor handling systems. Matching the gearbox ratio to the available hydraulic power and desired line pull is a key step in hydraulic winch selection.

A hydraulic winch usually incorporates a multi‑disc brake system that is spring‑applied and hydraulically released. This fail‑safe design means that when hydraulic pressure is removed—due to shutdown, failure, or emergency stop—the springs clamp the brake, locking the winch drum and holding the load.

Brakes can be installed inside the drum, integrated into the planetary gearbox, or mounted on the motor shaft. Key characteristics of a robust hydraulic winch brake system include:

- High static holding capacity to secure maximum rated loads.

- Smooth engagement to avoid shock loading of the structure and wire rope.

- Resistance to overheating during controlled lowering operations.

Safety can be further enhanced with overload protection systems, load indicators, and monitoring electronics. These features allow operators to avoid over‑tensioning the rope and provide early warning of abnormal operating conditions in the hydraulic winch.

The drum of the hydraulic winch stores the rope or wire and transfers torque from the drivetrain into linear pulling force on the line. Drum diameter, length, and groove design determine rope capacity and how line pull changes as layers build up.

Many heavy‑duty hydraulic winches feature:

- Steel drums with welded or machined flanges.

- Grooved surfaces for improved spooling.

- High‑capacity bearings on the drum shaft.

- Rigid side frames to maintain alignment.

Optional clutches—such as mechanical, hydraulic, or air‑actuated types—allow the drum to be disengaged from the drive train for free spooling. This is particularly useful when the operator needs to rapidly pull out line by hand or by another vehicle before using powered retrieval with the hydraulic winch.

A rigid support structure is equally important. Bases, mounting plates, and connection points must be designed to withstand full rated load, side loads from misaligned pulls, and dynamic forces from starting and stopping the hydraulic winch.

The hydraulic circuit defines how power flows through the hydraulic winch system and greatly affects performance, response, and safety. A basic open‑center or closed‑center circuit typically includes:

- A reservoir or tank for hydraulic fluid.

- A suction line from the tank to the pump.

- A pump that pressurizes the fluid.

- A pressure line to the valve stack.

- Directional and flow control valves.

- A hydraulic motor driving the winch.

- Return lines back to the reservoir.

- Safety devices like relief and check valves.

When the operator actuates the control lever or remote, the directional valve ports high‑pressure oil to the appropriate side of the motor, spinning the drum in the required direction. Flow control devices can slow down the motor for precise positioning or allow higher flow for faster line speed when needed.

Counterbalance or brake valves hold loads in place even if a hose fails or the pump stops, preventing uncontrolled descent. In lifting or man‑riding applications, these components are critical to meet safety standards.

More advanced hydraulic winch systems use closed‑loop circuits in which the motor and pump form a dedicated loop, with only a small charge circuit connected to the tank. This arrangement improves efficiency, dynamic response, and control accuracy, particularly in high‑duty industrial or offshore winch applications.

Hydraulic winches are chosen over electric alternatives when reliability, power density, and continuous duty are essential. Key advantages include:

- High pulling capacity: Hydraulic systems can generate very high torque in a compact package, allowing a hydraulic winch to pull loads far beyond what similarly sized electric winches can handle.

- Continuous duty cycle: Hydraulic oil carries heat away from the motor and gearbox, so a hydraulic winch can run for long periods without overheating, ideal for heavy industrial tasks.

- Smooth, controllable torque: Hydraulic winches offer excellent low‑speed control and smooth acceleration, reducing shock loads on ropes, anchors, and structures.

- Durability in harsh environments: Sealed hydraulic components and robust housings make hydraulic winches better suited to wet, dirty, or corrosive conditions, such as offshore and mining environments.

- Integration with existing hydraulic systems: Many machines—excavators, cranes, trucks, and marine power packs—already have hydraulic power available, making it straightforward to add or upgrade to a hydraulic winch.

In addition, a hydraulic winch can be designed with customized line speeds, drum sizes, controls, and interfaces, allowing manufacturers to tailor solutions for very specific applications.

Because of these performance characteristics, hydraulic winches are used across a wide spectrum of industries and tasks.

In maritime environments, hydraulic winches are key elements of deck machinery. Typical uses include:

- Anchoring and mooring of vessels and offshore platforms.

- Towing operations for ships, barges, and offshore structures.

- Handling subsea equipment, ROVs, and cables.

- Positioning floating structures in rough seas.

Marine hydraulic winches often require corrosion‑resistant materials, marine‑grade coatings, and robust sealing to withstand saltwater, spray, and UV exposure. For hazardous zones on offshore platforms, explosion‑proof motors and components may be specified.

On construction sites, in open‑pit mines, and in infrastructure projects, hydraulic winches support many critical operations:

- Lifting and lowering heavy structural elements such as beams and precast panels.

- Pulling pipe strings, conveyors, or heavy machinery into place.

- Assisting piling rigs, drilling rigs, and foundation machines with hoisting duties.

In these sectors, planetary hydraulic winch drives with integrated brakes are popular due to their compact size and high torque capability. Mounting flexibility allows integration into cranes, truck bodies, drilling masts, and purpose‑built construction equipment.

Recovery trucks, utility service vehicles, and off‑road equipment frequently rely on hydraulic winches powered by onboard hydraulic systems. Common use cases include:

- Vehicle recovery and towing on highways and in off‑road conditions.

- Loading and unloading equipment onto flatbeds and trailers.

- Handling utility poles, transformers, and line tensioning hardware.

- Self‑recovery in extreme off‑road applications where electric winches might overheat or lack power.

Because they are powered by an engine‑driven pump rather than batteries, these vehicle‑mounted hydraulic winches can operate continuously as long as the engine is running, which is a major advantage in professional recovery and utility work.

Hydraulic winches play a vital role in oil and gas operations, as well as in wind, hydro, and other energy industries. They are used for:

- Lifting and moving heavy drilling equipment and tubulars.

- Pulling and laying pipelines or power cables.

- Anchoring and stabilizing rigs and platforms.

- Handling heavy tools for inspection and maintenance.

In these demanding environments, a hydraulic winch is valued for high lifting capacity, precise control, and reduced maintenance requirements. The ability to withstand extreme temperatures, hazardous atmospheres, and continuous operation cycles makes hydraulic winch systems especially attractive for energy projects.

Hydraulic winch technology is evolving, combining rugged mechanical systems with smart electronics and advanced materials.

Modern trends include:

- Integrated sensing and monitoring: Sensors for pressure, temperature, speed, and line tension can be integrated into the hydraulic winch, enabling predictive maintenance and remote diagnostics.

- Electronic control and automation: Electronic controllers can manage winch speed, torque limits, synchronized multi‑winch operation, and automatic positioning functions, improving both safety and productivity.

- Improved materials and coatings: Advanced surface treatments and corrosion‑resistant materials extend the life of drums, gears, and housings, particularly in marine and offshore environments.

- Environmentally friendly fluids: New hydraulic fluids with lower environmental impact and improved fire resistance are being adopted, helping hydraulic winch systems meet stricter environmental regulations.

These enhancements preserve the core strengths of the hydraulic winch—power, durability, and reliability—while adding digital intelligence and sustainability.

Hydraulic winch technology is a powerful blend of hydraulic, mechanical, and control engineering, transforming fluid pressure into precisely controlled, high‑torque drum rotation for heavy pulling and lifting tasks. By combining high‑torque hydraulic motors, efficient planetary gearboxes, fail‑safe multi‑disc brakes, and carefully designed hydraulic circuits, a hydraulic winch delivers the strength, safety, and reliability required in marine, construction, energy, and recovery applications.

From basic vehicle‑mounted units to sophisticated offshore and industrial systems, the hydraulic winch remains one of the most versatile and dependable tools for handling heavy loads. As sensing, control, and material technologies advance, hydraulic winches are becoming smarter and more efficient, while retaining the rugged characteristics that make them indispensable in the world's toughest working environments.

A hydraulic winch is a winching system powered by pressurized hydraulic fluid instead of electricity. It uses a hydraulic pump, motor, and control valves to drive a drum that winds or unwinds rope or cable. This configuration provides high pulling power, long duty cycles, and reliable performance in demanding conditions such as marine, construction, and recovery work.

An electric winch uses an electric motor powered by batteries or mains electricity, while a hydraulic winch uses hydraulic fluid pressurized by a pump driven by an engine or power pack. Hydraulic winches typically offer higher continuous pulling capacity, better resistance to overheating, and smoother low‑speed control, making them more suitable for heavy‑duty and long‑duration operations.

Hydraulic winches are widely used in marine and offshore operations for anchoring, towing, mooring, and handling subsea equipment. On land, they appear on cranes, drilling rigs, construction machinery, mining equipment, recovery trucks, utility vehicles, and specialized industrial systems wherever high pulling forces and continuous duty are required.

Routine maintenance for a hydraulic winch includes checking fluid levels and quality, inspecting hoses, fittings, and seals for leaks or damage, and confirming correct operation of valves and brakes. Periodic inspection of the drum, rope or cable, planetary gearbox, and mounting structure is also essential to ensure safe operation and extend service life under heavy loads and harsh conditions.

Sizing a hydraulic winch starts with defining required line pull, line speed, duty cycle, and safety factor for the job. You then match these requirements to available hydraulic power (pressure and flow), choose an appropriate planetary gearbox ratio, select a drum diameter and rope capacity, and verify that the winch meets relevant industry standards. Working with a specialized manufacturer or engineering team helps ensure that the hydraulic winch is correctly sized and configured for your specific project.

1. https://www.bloommfg.com/blog/post/everything-you-need-to-know-about-hydraulic-winches

2. https://www.bloommfg.com/blog/post/everything-you-need-to-know-about-marine-hydraulic-winches

3. https://www.bloommfg.com/blog/post/hydraulic-winches-power-and-efficiency-for-industrial-operations

4. https://www.bloommfg.com/blog/post/how-hydraulic-winches-enhance-efficiency-in-the-oil-gas-industry

5. https://landmarktools.com/blogs/guides/how-does-a-hydraulic-winch-work

6. https://www.tu.biz/video-blog/english/how-does-a-hydraulic-winch-work

7. https://www.ini-hydraulic.com/news/how-hydraulic-winches-work-and-their-applications

8. https://apollooffroad.com/blogs/default-blog/blog-how-does-a-hydraulic-winch-work

9. https://www.winchhire.co.uk/why-hydraulic-winches-are-imperative-for-industrial-projects/

10. https://zhihete.com/top-5-benefits-of-using-a-hydraulic-winch-for-your-projects/

11. https://miseamachinery.com/hydraulic-winch/

12. https://hydraulicwinchco.com/industry-uses/

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Armenia

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Iran

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Turkey

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Russia

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Indonesia

Top Heavy Equipment Undercarriage Manufacturers And Suppliers in Australia

Top Heavy Equipment Undercarriage Manufacturers and Suppliers in Brazil

Top VTS Track System Parts Manufacturers And Suppliers in Hungary

Top VTS Track System Parts Manufacturers And Suppliers in Greece

Top VTS Track System Parts Manufacturers And Suppliers in Luxembourg