Views: 222 Author: Amanda Publish Time: 2026-01-08 Origin: Site

Content Menu

● Understanding Hydraulic Winch Basics

● PTO Winch vs Hydraulic Winch

● Key Components Needed for Conversion

>> Hydraulic Motor and Winch Interface

>> Reservoir, Filtration, and Cooling

>> Control Valves and Safety Devices

>> Hoses, Fittings, and Structural Supports

● Design Considerations Before Conversion

>> PTO and Engine Capabilities

● Step‑by‑Step Conversion Process

>> Step 1: Document the Existing PTO Winch Setup

>> Step 2: Remove the Mechanical Driveline

>> Step 3: Install the PTO‑Driven Pump

>> Step 4: Mount the Hydraulic Motor on the Winch

>> Step 5: Install Reservoir, Filters, and Return Lines

>> Step 6: Add the Control Valve and Safety Elements

>> Step 7: Connect and Route Hoses

>> Step 8: Fill, Bleed, and Test the Hydraulic Winch

● Performance Optimization and Maintenance

>> Routine Inspection and Service

● FAQ

>> 1. What are the main benefits of converting to a hydraulic winch?

>> 2. Can my existing PTO handle a hydraulic winch system?

>> 3. How do I choose the right pump and motor for a hydraulic winch?

>> 4. Do I need extra cooling for my hydraulic winch system?

>> 5. Is a hydraulic winch safe for use on slopes and in lifting applications?

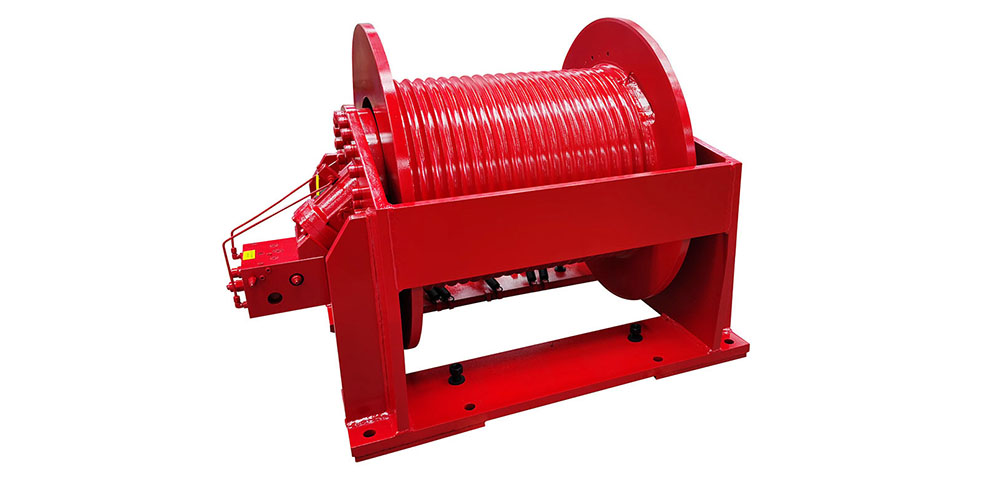

Converting a traditional PTO winch into a Hydraulic Winch system is one of the most effective upgrades for improving control, safety, and duty cycle in demanding applications such as recovery, forestry, construction, and industrial hauling. A properly designed hydraulic winch uses a PTO‑driven pump, hydraulic motor, reservoir, and valves to replace the original mechanical driveline while retaining or even increasing pulling capacity and line speed flexibility.[1][2]

A hydraulic winch converts hydraulic energy into mechanical rotation by feeding pressurized oil from a pump into a hydraulic motor connected to the winch drum or gearbox. The hydraulic fluid flows through hoses and valves between the pump, motor, and reservoir, creating a closed‑loop or open‑loop circuit that can be finely controlled.[2][3][4]

Key elements in any hydraulic winch setup include:[3][2]

- Hydraulic pump (often driven directly from the PTO)

- Hydraulic motor sized for desired torque and speed

- Gearbox (planetary or worm gear) integrated with the winch

- Directional control valve (forward/neutral/reverse)

- Reservoir, filter, breather, and cooling arrangements

- Safety devices such as relief valves, brake valves, and load‑holding brakes

Compared with mechanical PTO winches, a hydraulic winch offers smoother modulation at very low speeds, excellent stall characteristics, and the ability to run for long periods without overheating.[5][3]

PTO winches and hydraulic winches both harness engine power, but they use fundamentally different transmission methods. Understanding these differences helps in planning the conversion.[6][1]

- A PTO winch is driven mechanically through shafts, U‑joints, and gears that connect the transmission PTO output directly to the winch input.[7][8]

- A hydraulic winch uses the PTO to spin a hydraulic pump, which produces oil flow and pressure that drive a hydraulic motor attached to the winch drum or gearbox.[9][2]

Mechanical PTO systems can be efficient but tend to be less flexible for remote control, and they expose rotating shafts that need guarding. Hydraulic winch systems replace those shafts with hoses, allow more flexible winch placement, and enable the use of remote or proportional controls to manage pulling operations.[10][11][2][7]

From a duty cycle perspective, a hydraulic winch can work for longer periods than electric winches and avoids the shock loading that mechanical PTO shafts can transmit during sudden starts or stops.[3][5]

Converting from a PTO winch to a hydraulic winch drive involves adding or modifying several major components.[1][9]

The pump is the heart of the system because it converts mechanical power from the PTO into hydraulic power.[4][9]

- The pump displacement (cc/rev) and maximum pressure rating must match the required flow and pressure for the hydraulic winch motor.[4][9]

- A correctly matched pump will deliver enough flow at typical engine speeds to reach the desired line speed, without overloading the PTO or gearbox.[8][10]

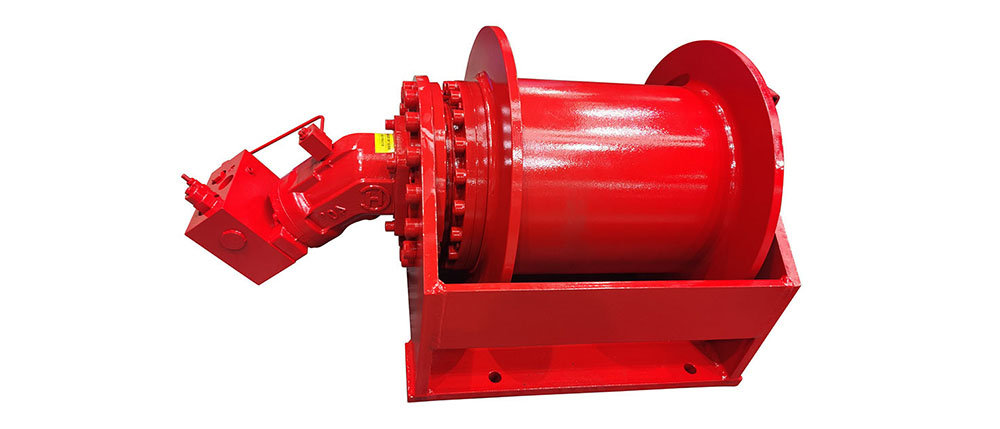

The hydraulic motor replaces the mechanical shaft as the direct driver of the winch.[10][1]

- High‑torque low‑speed motors or radial piston motors are often used for heavy‑duty hydraulic winch applications due to their ability to deliver large torque at modest speeds.[12][3]

- The motor must be mounted securely on a bracket or adapter that aligns its shaft with the winch input, using a coupler or gear interface designed for the maximum torque.[1][3]

A properly sized reservoir and filtration system maintain oil quality and temperature.[11][2]

- The tank volume is often chosen as a multiple of pump flow per minute, allowing oil to dwell long enough for air release and cooling.[2][11]

- Return‑line filters, suction strainers where appropriate, and breathers are required to keep the hydraulic winch oil clean and free from contaminants that can damage pumps and motors.[11][3]

Control valves regulate the direction, speed, and pressure of the hydraulic winch circuit.[9][2]

- A directional control valve provides forward‑neutral‑reverse functions and can integrate pressure relief, load check, and optional flow control.[4][9]

- Relief valves protect against over‑pressure, while counterbalance or brake valves help hold loads safely and prevent uncontrolled drum rotation.[11][4]

Hoses and hardware must match the pressure, flow, and environmental conditions of the hydraulic winch system.[2][9]

- Use hoses rated well above maximum working pressure, with robust abrasion‑resistant outer covers and high‑quality crimped fittings.[9][2]

- Structural supports and guards protect the hydraulic pump, motor, and hoses from impact, debris, and heat sources in real‑world industrial and off‑road applications.[10][1]

Planning is essential before removing the mechanical driveline and committing to a full hydraulic winch conversion.[13][1]

Start by clarifying the loads and operating conditions your hydraulic winch must handle.[3][9]

- Maximum line pull required and typical working load.

- Desired line speed at those loads and during free‑spooling or low‑speed positioning.

- Expected duty cycle, such as intermittent logging pulls or near‑continuous industrial use.

These parameters will drive the selection of the pump displacement, system pressure, and motor size to achieve the right balance of speed and torque.[4][9]

The PTO and engine must be able to support the power demand of the hydraulic winch system.[8][10]

- Confirm the PTO's maximum torque and allowable continuous power rating.

- Check engine operating ranges where the hydraulic winch will work most often, ensuring that pump flow remains adequate at idle or moderate RPM when precise control is required.

Oversizing the hydraulic winch components can overload the PTO or engine; undersizing them can result in slow, weak pulling performance.[9][4]

The physical integration of a hydraulic winch system can be more flexible than a purely mechanical PTO shaft, but it still requires careful layout.[1][10]

- Identify space for the pump, reservoir, and valve block that allows safe service access and adequate airflow.

- Plan hose routing to avoid pinch points, sharp bends, exhaust heat, and potential impact zones.

Using compact, integrated hydraulic winch units with built‑in motors and brakes can simplify mounting on crowded chassis or tracked undercarriage systems.[13][3]

The following workflow outlines how to convert a PTO winch into a hydraulic winch system while retaining as much of the existing structure as practical.[10][1]

Before disassembly, note how the current PTO winch is installed.[8][10]

- Record shaft lengths, support bearings, and mounting points.

- Measure winch drum dimensions and gear ratios if available, as they influence torque requirements and line speed.

This information will help you design a hydraulic winch drive that matches or improves on the original performance.[4][9]

Once planning is complete, carefully remove the mechanical PTO driveline.[1][10]

- Remove PTO shafts, couplings, guards, and intermediate supports between the PTO and the winch.

- Inspect the winch input for compatibility with a hydraulic motor coupling, and check the internal gearbox and drum for wear or damage.

Retaining a sound winch gearbox can reduce cost, since the hydraulic motor can drive this input directly.[3][8]

The pump is mounted directly or via an adapter to the PTO output.[9][4]

- Use the correct PTO pump mount, including a suitable flange and alignment hardware.

- Connect a short, large‑diameter suction hose from the pump inlet to the reservoir, and ensure the oil level is above the pump inlet to avoid air entrainment.

The pressure outlet of the pump is then routed towards the control valve for the hydraulic winch.[2][11]

Mounting the motor correctly is critical for reliable hydraulic winch operation.[10][1]

- Fabricate or purchase a motor bracket that locates the motor precisely relative to the winch input shaft.

- Use a coupler that can handle peak torque and slight misalignment while protecting bearings on both the motor and winch.

Careful alignment reduces vibration and increases the life of both hydraulic winch components and mechanical gears.[3][1]

With the pump and motor in place, integrate the fluid management hardware.[11][2]

- Mount the reservoir in a protected but accessible area, leaving room above it for filling and breather service.

- Connect return lines from the control valve and hydraulic winch motor back to the reservoir through the return‑line filter.

If the motor requires a separate case drain, route this line directly back to the tank at a point below the oil level to minimize aeration.[2][11]

The control valve will become the operator's main interface with the hydraulic winch.[2][9]

- Install a directional control valve with suitable flow capacity and an ergonomic lever or remote control option.

- Ensure that pressure relief settings are appropriate for the motor and winch structure, and consider using a counterbalance valve for load‑holding on slopes.

By tuning these settings, operators can achieve very smooth and predictable hydraulic winch behavior.[4][9]

Connect all plumbing between the pump, valve, motor, and reservoir with high‑quality hoses and fittings.[9][2]

- Use clamps and protective sleeves where hoses pass close to edges or moving components.

- Provide enough slack for chassis flex and suspension movement without allowing hoses to sag into danger zones.

Good hose routing greatly improves the long‑term reliability of a hydraulic winch system.[11][2]

After assembly, the hydraulic winch system must be filled and tested.[11][2]

- Fill the reservoir with the recommended hydraulic oil and check all connections.

- Start the engine, engage the PTO at low RPM, and slowly operate the control valve to purge air from the motor and lines.

Once the system is responsive and quiet, gradually increase load on the hydraulic winch while monitoring pressure, temperature, and any signs of leakage or vibration.[3][11]

A hydraulic winch conversion is most effective when the system is optimized and maintained over time.[5][13]

Fine‑tuning may be required to balance speed and pulling force.[4][9]

- Adjust flow control or engine RPM to set comfortable winch speeds for spooling, recovery, and precision positioning.

- Verify maximum pulling capacity with calibrated loads and ensure relief valve settings keep stresses within design limits.

If the hydraulic winch proves too slow or too fast for the application, motor displacement or pump size can be revisited.[9][4]

Regular maintenance increases the life of both the hydraulic winch and the host vehicle.[2][11]

- Check oil level and cleanliness, changing the fluid and filters at intervals recommended for similar hydraulic winch systems.

- Inspect hoses, fittings, and structural mounts for wear, corrosion, and fatigue, particularly after heavy use or accidental overloads.

Addressing small leaks and performance changes early prevents major failures in the hydraulic winch drive.[3][11]

Converting a mechanical PTO winch to a hydraulic winch system transforms a conventional driveline into a versatile, high‑performance pulling solution suitable for modern industrial, off‑road, and recovery operations. By carefully selecting a PTO‑driven pump, hydraulic motor, reservoir, controls, and safety devices, and by integrating them correctly with the existing winch hardware, operators can achieve smoother control, higher duty cycles, and better protection for both equipment and personnel. With proper design, installation, and maintenance, a hydraulic winch upgrade delivers long‑term value, reliability, and performance that far surpass traditional mechanical PTO drives.[5][13][1][2][3][9]

A hydraulic winch provides smoother low‑speed control, higher continuous duty capability, and easier remote operation compared to a purely mechanical PTO winch. It also allows more flexible mounting options and can protect the drivetrain from shock loads through properly set relief valves.[5][2][3][9]

Most factory PTO units can drive a hydraulic pump for a hydraulic winch, provided their power and torque ratings are not exceeded. Always compare the anticipated hydraulic pump demand with the PTO manufacturer's specifications and leave safety margins for continuous operation.[8][10][9]

Pump and motor selection for a hydraulic winch depends on desired line speed, pulling force, available engine power, and system pressure. Manufacturers usually provide charts or tools that correlate motor displacement, flow, and pressure with line pull and drum speed, helping to size components accurately.[3][4][9]

Many light and medium‑duty hydraulic winch systems rely on the reservoir for cooling, but heavy, continuous duty applications may require an oil cooler. Monitoring fluid temperature during long pulls will indicate whether additional cooling is necessary to protect pump and motor life.[11][2][3]

When paired with appropriate brake valves, drum brakes, and correctly set relief valves, a hydraulic winch provides excellent load control on slopes and during vertical lifts. Proper system design, including load‑holding valves and adherence to rated capacities, is essential for safe operation in these demanding conditions.[2][4][11][3]

[1](https://www.steelsoldiers.com/threads/hydraulic-conversion-of-pto-winch.78933/)

[2](https://landmarktools.com/blogs/guides/how-does-a-hydraulic-winch-work)

[3](https://www.bloommfg.com/blog/post/everything-you-need-to-know-about-hydraulic-winches)

[4](https://crossmfg.com/resources/technical-and-terminology/hydraulics-systems-diagrams-and-formulas)

[5](https://www.orangetractortalks.com/forums/threads/winch-hydraulic-vs-pto.46872/)

[6](https://www.tractorbynet.com/forums/threads/winch-hydraulic-vs-pto.428436/)

[7](https://forum.expeditionportal.com/threads/pto-winch.233596/)

[8](https://www.thetruckersreport.com/truckingindustryforum/threads/setting-up-a-30-ton-mechanical-winch.1454136/)

[9](https://winchesinc.com/hydraulic-system-design/)

[10](https://www.steelsoldiers.com/threads/how-to-add-a-winch.86292/)

[11](https://www.metalforms.com/videosConcreteForms/HydraulicVideo)

[12](https://arbtalk.co.uk/forums/topic/95659-pto-winch-to-hydraulic/)

[13](https://www.steelsoldiers.com/threads/converting-pto-driven-equipment-to-hydraulic-and-the-decent-into-madness.194095/)