Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

● What Rebuilding a Hydraulic Winch Means

● Safety Preparation Before Rebuild

● Tools, Manuals, and Technical Data

● Step 1 – External Inspection and Diagnosis

● Step 2 – Cleaning the Hydraulic Winch

● Step 3 – Disconnecting the Hydraulic Winch

● Step 4 – Disassembling the Hydraulic Winch

● Step 5 – Inspecting Components for Wear and Damage

● Step 6 – Replacing Seals, Bearings, and Worn Parts

● Step 7 – Cleaning and Lubricating Internal Parts

● Step 8 – Reassembling the Hydraulic Winch

● Step 9 – Reinstalling the Hydraulic Winch on the Machine

● Step 10 – Filling, Bleeding, and Commissioning

● Common Problems After a Hydraulic Winch Rebuild

● Maintenance Tips to Extend Hydraulic Winch Life

● Why Work With a Specialist Manufacturer

● FAQ

>> 1. How often should a hydraulic winch be rebuilt?

>> 2. What are the signs that a hydraulic winch needs rebuilding?

>> 3. Can a hydraulic winch be rebuilt in the field, or must it go to a workshop?

>> 4. Do I always need to replace the hydraulic motor during a rebuild?

>> 5. How can I make a rebuilt hydraulic winch last longer?

Rebuilding a hydraulic winch restores power, reliability, and safety so the unit can continue handling demanding lifting and pulling work for many years. A structured hydraulic winch rebuild covers inspection, cleaning, disassembly, component replacement, reassembly, and final testing to near‑factory standards.[1][2]

A hydraulic winch rebuild is a controlled overhaul in which major components are opened, inspected, and renewed, not just patched with minor repairs. During a rebuild, the hydraulic winch drum, brake, hydraulic motor, planetary gearbox, bearings, and seals are evaluated and replaced where necessary so the hydraulic winch can safely deliver its rated line pull again.[3][1]

A properly rebuilt hydraulic winch will:

- Recover lost line pull and improve line speed consistency.

- Reduce hydraulic leaks, overheating, and noise from the hydraulic winch drivetrain.

- Lower the risk of rope failure, uncontrolled load movement, and unplanned downtime on critical jobs.[4][5]

Before any work begins, the hydraulic winch and surrounding machine must be placed in a safe, de‑energized condition. Failing to isolate a hydraulic winch can lead to sudden drum rotation or pressurized oil release, which are serious hazards.[2][4]

Essential safety steps for a hydraulic winch rebuild:

- Depressurize the hydraulic system by shutting down the power source, returning valves to neutral, and bleeding residual pressure.[2][4]

- Lock out and tag out engine, electric motor, or power pack controls so no one can start the hydraulic winch circuit accidentally.

- Secure the hydraulic winch drum mechanically to prevent rotation and ensure the rope or cable is fully unwound or safely anchored.

- Use slings, hoists, and supports rated for more than the hydraulic winch weight and the heaviest subassembly you will remove.[1][2]

Accurate information is the foundation of a safe hydraulic winch rebuild. OEM manuals, exploded views, and torque charts guide every step of the process and ensure the hydraulic winch is rebuilt to specification.[6][7]

Helpful resources for a hydraulic winch overhaul:

- OEM user, service, and maintenance manuals with torque specs, hydraulic diagrams, and parts lists.[7][8]

- Exploded diagrams showing the hydraulic winch drum, planetary gearbox, brake pack, hydraulic motor, and mounting frame.[3][6]

- Line pull rating charts and hydraulic system data (pressure and flow) for the specific hydraulic winch installation.

- Training videos that show real‑world winch disassembly and reassembly to visualize each stage of a hydraulic winch rebuild.[9][10]

Before opening the hydraulic winch, perform a detailed external inspection and collect operational symptoms from operators or maintenance logs. This helps you understand whether the hydraulic winch is suffering from low power, slipping brake, structural damage, or hydraulic problems upstream.[11][1]

Focus points during hydraulic winch diagnosis:

- Look for external oil leaks from the hydraulic motor shaft seal, brake cover, gearbox housing, and hydraulic ports.

- Check for uneven rope spooling that might indicate a bent drum, misaligned hydraulic winch frame, or worn bearings.

- Note any abnormal noise such as grinding, whining, or clunking during hydraulic winch operation, which can indicate gear or bearing damage.

- Evaluate line pull weakness, jerky motion, or slow speed, which may point to internal wear, brake drag, or hydraulic supply issues.[12][4]

Cleanliness is critical because dirt and abrasive particles can damage internal surfaces once the hydraulic winch is opened. The goal is to prevent external contamination from entering the hydraulic winch while you work.[5][2]

Best practices when cleaning a hydraulic winch:

- Remove mud, sand, rust flakes, and old grease from around covers, bolts, and joints with brushes and suitable cleaning agents.[5][12]

- Pay attention to the areas where the hydraulic winch motor, brake, and gearbox meet the frame, because dirt easily falls inside when these parts are removed.

- Plug or cap nearby hydraulic lines to keep contamination out of the rest of the hydraulic system during the rebuild.[2][3]

Once the area is clean and safe, isolate the hydraulic winch from the machine so you can remove it or open it in place. Proper disconnection preserves the hydraulic system integrity and makes reinstallation much easier.[8][2]

Typical disconnection tasks for a hydraulic winch:

- Label and disconnect pressure, return, and case drain hoses from the hydraulic winch motor valve block, capturing any oil that drains out.

- Remove electrical connections to solenoid valves, sensors, or limit switches associated with the hydraulic winch controls.

- Loosen and remove the mounting bolts or pins that fasten the hydraulic winch frame to the carrier structure, using supports to carry the weight.

- If rebuilding on the machine, ensure the hydraulic winch is adequately supported before removing any fasteners that bear its weight.[12][2]

Disassembly exposes the internal components of the hydraulic winch so they can be inspected, cleaned, and renewed. Work methodically, keep parts organized, and document every stage so the hydraulic winch goes back together correctly.[1][3]

Typical hydraulic winch disassembly sequence:

- Remove the rope or cable from the hydraulic winch drum and protect it from damage if it will be reused.

- Take off external guards, covers, and the brake housing to gain access to the hydraulic winch brake pack and drum.

- Separate the hydraulic motor from the brake or gearbox flange, noting shaft key positions and spline conditions.

- Open the planetary gearbox and remove gear stages, carriers, and bearings in order, keeping components laid out as they were installed.

- Slide the drum off its bearings if required, marking orientation to simplify reassembly of the hydraulic winch.[3][12]

Inspection is the heart of a hydraulic winch rebuild because it determines which components must be replaced and which can be reused. The goal is to identify early damage in the hydraulic winch before it leads to catastrophic failure in service.[5][1]

Key inspection points in a hydraulic winch:

- Planetary gears and sun gears: look for pitting, scoring, chipped teeth, and excessive backlash.

- Bearings and races: check for roughness, discoloration from overheating, and looseness on shafts or in housings.

- Brake discs and friction plates: measure thickness, inspect for glazing, warping, or oil contamination that will cause slip.

- Drum and frame: examine the cable groove surface for grooving and the flanges for cracks or distortion.

- Hydraulic motor: inspect the shaft, seals, and mounting face; internal wear is often checked by specialist shops using flow and leakage tests.[11][5]

Rebuild kits for a hydraulic winch usually include seals, gaskets, O‑rings, and sometimes bearings and friction discs. Replacing these wear items is essential to restore the hydraulic winch to reliable condition and prevent leaks.[8][2]

Typical replacements during a hydraulic winch rebuild:

- All shaft seals, O‑rings, and gaskets in the brake housing, gearbox, and motor interface.

- Bearings supporting the drum, planetary gear carriers, and input shafts, especially if there is any sign of wear or noise.

- Brake friction plates and steel plates if they are worn beyond limits or contaminated with oil.

- Damaged gears, carriers, or shafts that fail inspection or exceed allowable wear tolerances.[7][3]

Before reassembly, every hydraulic winch component should be cleaned and prepared to prevent contamination and premature wear. Cleanliness at this stage determines how long the rebuilt hydraulic winch will run without problems.[2][5]

Good practices for hydraulic winch internal cleaning:

- Wash metal parts with suitable solvents or cleaning fluids and dry them thoroughly to remove sludge, varnish, and metal particles.

- Clean out oil passages, housings, and gear cavities so fresh lubricant and hydraulic oil can circulate freely in the hydraulic winch.

- Apply the correct assembly lubricants to bearings, gear teeth, and brake plates following the OEM recommendations.[8][5]

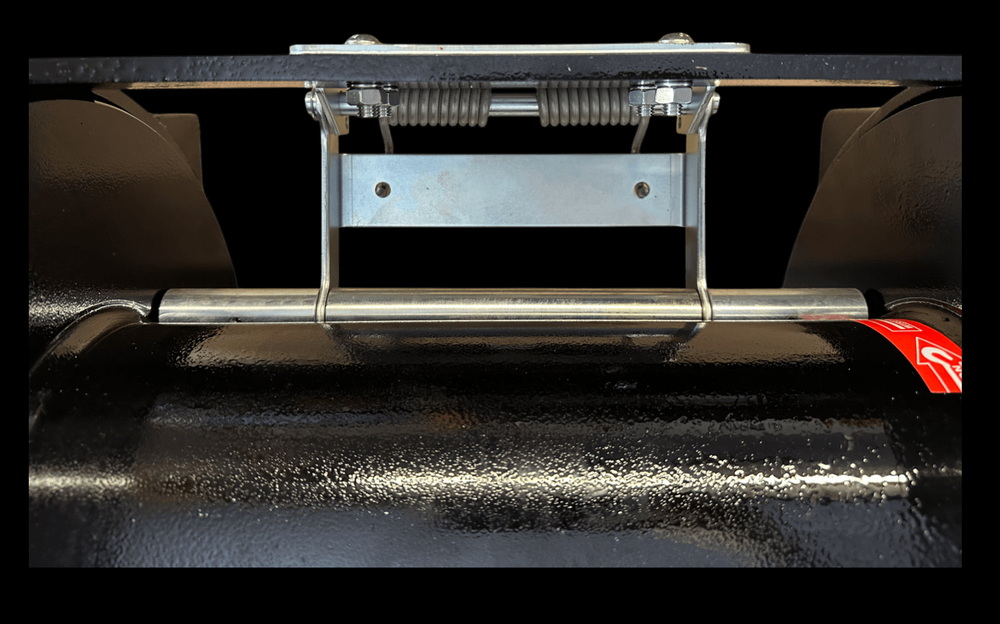

Reassembly reverses the disassembly steps but demands careful attention to orientation, clearances, and torque values. Accurate reassembly ensures the hydraulic winch operates smoothly and maintains internal alignment.[7][3]

Important points during hydraulic winch reassembly:

- Install bearings and seals using appropriate drivers so they seat squarely without damage.

- Rebuild the planetary gearbox in the exact sequence shown in the manual, confirming gear mesh and backlash.

- Stack brake discs and plates in the specified order, checking clearances and spring forces according to the hydraulic winch brake design.

- Align the hydraulic motor shaft with the gearbox or brake spline carefully to avoid seal damage and misalignment.

- Tighten all hydraulic winch fasteners to specified torque using calibrated tools.[6][7]

Once rebuilt, the hydraulic winch must be securely mounted and precisely aligned with the carrier structure or chassis. Poor mounting can cause vibration, misalignment, and early failure of the hydraulic winch.[12][2]

Key steps when installing a rebuilt hydraulic winch:

- Clean the mounting surfaces and check for distortion or damage that could twist the hydraulic winch frame.

- Position the hydraulic winch using lifting equipment and fasten it with the correct grade and size of bolts or pins.

- Reconnect hydraulic hoses and fittings to the winch motor, brake valves, and any auxiliary circuits, using new seals or washers.

- Verify hose routing so lines are protected from pinch points, sharp edges, and excessive heat around the hydraulic winch.[8][2]

The final stage of a hydraulic winch rebuild is filling, bleeding, and controlled testing under load. This step confirms that the hydraulic winch operates safely and that the rebuild has resolved previous problems.[12][2]

Commissioning a rebuilt hydraulic winch includes:

- Filling the gearbox or brake cavity with the specified oil and confirming levels with sight glasses or plugs.

- Bleeding air from the hydraulic winch motor circuit if required, following OEM procedures to avoid cavitation.

- Performing low‑speed function tests in both directions with no load to check for leaks, abnormal noises, or overheating.

- Gradually increasing load toward the rated line pull while monitoring pressure, speed, and brake performance of the hydraulic winch.[1][2]

Even after a careful rebuild, some hydraulic winch issues may appear during initial operation. Early troubleshooting prevents damage and helps fine‑tune the rebuilt hydraulic winch.[13][11]

Typical post‑rebuild issues in a hydraulic winch:

- Slow or weak pulling: may indicate insufficient system pressure or flow, incorrect motor connection, or brake drag.

- Excessive noise or vibration: can be caused by misaligned gears, damaged bearings, or incorrect mounting of the hydraulic winch.

- Overheating of oil or gearbox: often linked to improper lubrication, excessive slip in the brake, or overloaded duty cycles.

- External leaks around covers and ports: usually result from mis‑seated seals, damaged O‑rings, or incorrect torque.[11][5]

A good rebuild is only the starting point; ongoing maintenance keeps the hydraulic winch in top condition. Regular checks and preventive actions significantly extend the service life of a hydraulic winch used in harsh environments.[5][12]

Useful maintenance habits for a hydraulic winch:

- Inspect the hydraulic winch regularly for leaks, loose fasteners, and abnormal noise during operation.

- Keep the rope, drum, and surrounding structure clean to prevent corrosion and contamination of the hydraulic winch components.

- Follow OEM schedules for gearbox oil changes, brake inspections, and hydraulic filter replacements.

- Monitor hydraulic oil cleanliness and temperature, because contaminated or overheated oil quickly damages the hydraulic winch motor and valves.[2][5]

Rebuilding a hydraulic winch can be done in‑house for simpler units, but complex or high‑capacity models benefit from the expertise of a specialist manufacturer. A manufacturer focused on hydraulic winch systems, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors can provide matched components and engineering support for demanding rebuilds.[1][5]

Partnering with a hydraulic winch expert helps you:

- Diagnose root causes behind repeated failures instead of replacing parts blindly.

- Upgrade older hydraulic winch designs with improved brakes, seals, and efficiency‑optimized components.

- Source complete hydraulic winch assemblies, repair kits, and custom solutions that fit your application and duty cycle.[8][1]

Rebuilding a hydraulic winch is a strategic investment that restores pulling performance, reduces downtime, and improves safety in heavy‑duty applications. By following structured steps—inspection, cleaning, disassembly, component renewal, reassembly, installation, and commissioning—you can return a hydraulic winch to reliable service and prolong its useful life. Pairing disciplined rebuild practices with ongoing preventive maintenance and, when needed, support from a dedicated hydraulic winch manufacturer ensures consistent, safe operation for demanding lifting and pulling tasks.[5][1]

The rebuild interval for a hydraulic winch depends on operating hours, load severity, environment, and maintenance quality. In heavy industrial or marine use, many operators schedule major hydraulic winch overhauls every few years or at fixed hour thresholds, while lighter applications may only need a rebuild when performance noticeably declines or inspections reveal serious wear.[4][5]

Common warning signs include reduced line pull, slower line speed, unusual noise, frequent overheating, and increasing hydraulic oil leaks around the hydraulic winch motor, gearbox, or brake housing. Visible damage to the rope or drum, repeated brake slippage, and metal contamination in drained oil samples are also strong indicators that a hydraulic winch requires a full rebuild rather than minor repairs.[11][1]

Some hydraulic winch rebuild tasks, such as seal replacement or minor brake service, can be performed on the machine if space, tools, and lifting equipment are available. However, full hydraulic winch overhauls that involve opening the gearbox, replacing bearings, or testing the hydraulic motor are often better done in a controlled workshop with access to presses, precision measuring tools, and dedicated test stands.[3][1]

A hydraulic winch rebuild does not automatically require a new motor, but the motor should be thoroughly inspected and tested. If flow tests show internal leakage, if the shaft is worn, or if seals repeatedly fail, then replacing or professionally remanufacturing the hydraulic winch motor is recommended to ensure the rebuilt winch can deliver full performance and efficiency.[2][5]

To extend the life of a rebuilt hydraulic winch, follow a structured maintenance plan with regular inspections, oil changes, and filter replacements as specified by the manufacturer. Keep the hydraulic winch clean, avoid overloading beyond rated line pull, monitor hydraulic oil cleanliness and temperature, and address small leaks or unusual noises immediately so minor issues do not escalate into major failures.[12][5]

[1](https://txfluidpower.com/hydraulic-winch-repair/)

[2](https://detailk2.com/media/pdf/20JP-manual.pdf)

[3](https://www.scribd.com/document/519622412/599028W-WINCHE)

[4](https://chiefengineerlog.com/2023/09/02/marine-hydraulic-winches-operation-maintenance-and-troubleshooting/)

[5](https://www.ini-hydraulic.com/news/hydraulic-winch-secrets-5-expert-backed-maintenance-tips-to-extend-lifespan)

[6](https://www.omfb.com/media/ARXIVAR_WEB/99713700110.pdf)

[7](https://www.cowdinsa.com/wp-content/uploads/2017/05/RPH35-2.pdf)

[8](https://toracompany.com/wp-content/uploads/2023/03/hydraulic-Winch-User-manual.pdf)

[9](https://www.youtube.com/watch?v=SNaPRVt9rus)

[10](https://www.youtube.com/watch?v=aG4ZhhrmaDw)

[11](https://www.str-subsea.com/2023/10/11/6-common-problems-associated-with-hydraulic-winches-and-how-to-overcome-them/)

[12](https://www.piercearrowinc.com/pages/winch-maintenance-how-to)

[13](https://www.winchhire.co.uk/common-problems-with-winches-troubleshooting-and-solutions/)