Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● Understanding a Laird Mixer Planetary Gearbox

● Key Components Inside the Planetary Gearbox

● Safety Precautions Before Disassembly

● Tools and Workspace Preparation

● Step‑by‑Step Planetary Gearbox Disassembly

>> Disconnect Power and Remove External Components

>> Drain Oil from the Planetary Gearbox

>> Remove the Mixer Planetary Gearbox from the Machine

>> Open the Planetary Gearbox Housing

>> Remove Ring Gear and Planet Carriers

>> Disassemble Individual Planetary Gear Sets

>> Inspect Bearings, Seals, and Output Shaft

● Cleaning and Documentation During Disassembly

● Measurement and Wear Evaluation

● Reassembly Considerations After Taking Apart the Gearbox

● Ideas for Visual Aids and Training Media

● Why Choose a Robust Planetary Gearbox for Mixers?

● Best Practices for Planetary Gearbox Maintenance

● Common Mistakes When Taking Apart a Mixer Planetary Gearbox

● Working With OEM and Aftermarket Support

● FAQ

>> 1. How often should a Laird mixer planetary gearbox be taken apart?

>> 2. Can a planetary gearbox on a mixer be disassembled without removing it from the machine?

>> 3. What type of lubricant is recommended for a mixer planetary gearbox?

>> 4. How can wear inside a planetary gearbox be detected early?

>> 5. Do all Laird mixers use the same planetary gearbox design?

A Laird mixer planetary gearbox is a compact, high‑torque transmission used to drive vertical and horizontal feed mixers in demanding agricultural and industrial environments, including truck‑mounted and trailer‑mounted mixers. Properly taking apart a Laird mixer planetary gearbox is essential for safe inspection, cleaning, and repair, and it must always be done following structured steps and strict safety rules.[1][2][3][4]

A Laird mixer planetary gearbox usually combines a radial piston or bent‑axis hydraulic motor with a multi‑stage planetary gear train to deliver high torque at low speed to the mixer augers. In this planetary gearbox, power flows from the motor shaft into a sun gear, which drives multiple planet gears within a ring gear to spread the load and increase torque while keeping the overall unit compact.[4][5][1]

Laird mixer planetary gearbox designs are built for continuous duty, so the housing, bearings, and gears are heavily loaded and require periodic inspection and maintenance. When disassembling a planetary gearbox on a mixer, the goal is to safely access these internal components for cleaning, wear inspection, and replacement before reassembling the drive in the original orientation.[6][1][4]

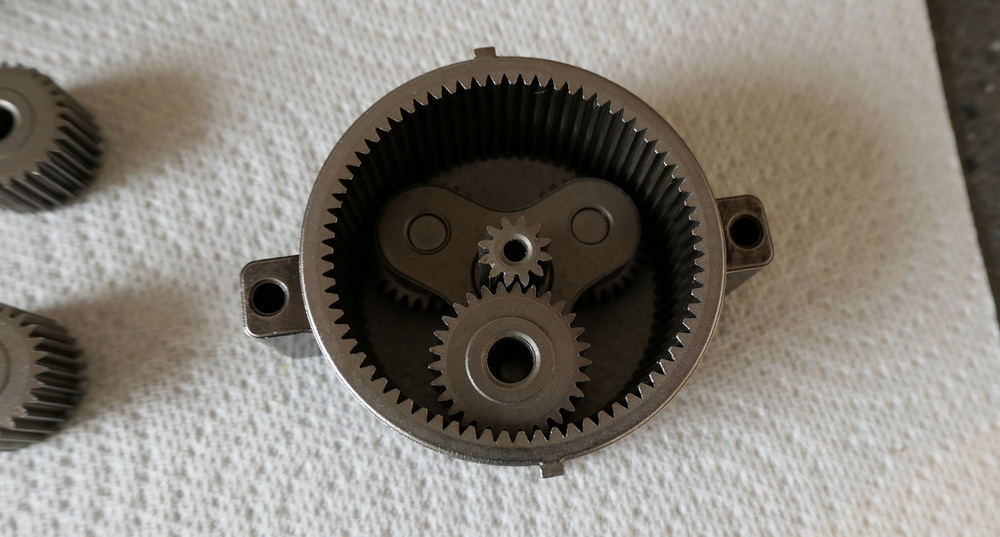

Inside a typical mixer planetary gearbox, the sun gear sits on the input shaft and is surrounded by three or more planet gears that rotate on pins mounted in a carrier. These planet gears mesh with an internal ring gear fixed to the housing, which enables high torque transfer within a relatively small planetary gearbox envelope.[1][4][6]

The carrier of the planetary gearbox is usually connected to the output flange or shaft that drives the mixer screw or auger, while bearings and seals support the rotating assemblies and retain the gear oil. Thrust washers, shims, and spacers inside the planetary gearbox help control axial clearances and load sharing between gears, which is critical for long life under shock loads.[7][4][6]

Before touching any planetary gearbox on a Laird mixer, the machine must be parked securely, engine or motor power must be shut off, and all stored energy in the hydraulic and mechanical drive system must be released. The mixer manufacturer's manual explicitly warns that improper disassembly of the gearbox or operation with open covers can cause serious injury, so lockout‑tagout procedures and support stands are mandatory.[2][8]

The planetary gearbox can be extremely heavy, and service manuals for similar gear drives require the use of hoists, slings, and safe lifting procedures to prevent dropping the unit during removal. Technicians must also wear appropriate PPE such as safety glasses, gloves, and steel‑toe footwear because draining hot oil, handling sharp gear teeth, and operating pullers can all present hazards.[8][4][6]

Service literature for multi‑stage planetary gear drives recommends assembling a full kit of tools before disassembly, including socket sets, hex keys, screwdrivers, soft‑face hammers, retaining ring pliers, pullers, and a suitable oil drain pan. For a Laird mixer planetary gearbox, additional equipment like lifting eyes, chains or slings, and an overhead hoist or jack is often needed because the gearbox may be mounted high on a vertical mixer.[4][6][1]

The work area around the mixer and planetary gearbox should be cleaned so dirt does not fall into the open housing, and a clean bench or table should be prepared with trays to keep fasteners and planetary gearbox components organized. Manuals for planetary gearbox drives also suggest scribing alignment marks across the housing split line before opening the unit to ensure correct rotational orientation when reassembling.[9][6][4]

A Laird mixer planetary gearbox disassembly process is similar to the procedures described for other industrial planetary gear drives and mixer planetary drives. The exact order can vary by model, but the following structured steps provide a typical workflow for safely taking apart a planetary gearbox on a mixer drive.[3][6][4]

First, isolate the mixer from any power source by shutting off the tractor PTO, engine, or electric motor and locking the controls so the mixer cannot start. Then the operator disconnects the hydraulic hoses or mechanical drive connection to the planetary gearbox, capping or plugging the ports to keep oil and contamination under control.[2][8][1]

Similar to other mixer planetary drive service procedures, any guards, covers, or shields around the planetary gearbox must be unbolted and set aside to expose the gearbox mounting bolts and shaft connections. If the planetary gearbox output shaft drives a mixer auger or vertical screw directly, the coupling or flange is typically loosened and removed to free the gearbox before lifting.[6][9][1][4]

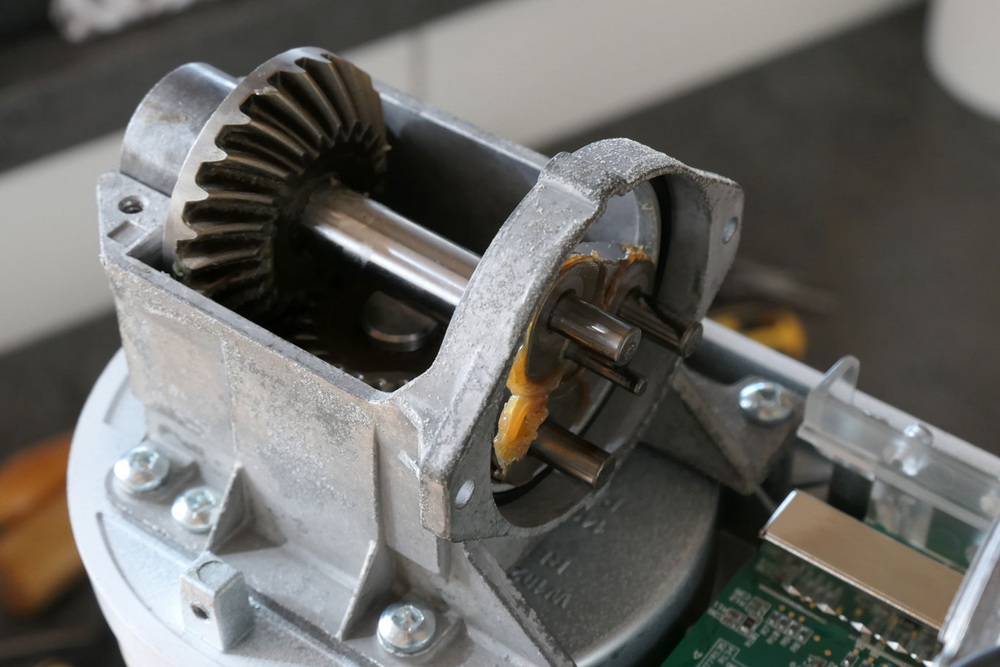

Before opening the housing of a planetary gearbox, service manuals instruct that the oil be drained by removing the drain plug or magnetic plug from the lower part of the case. The oil should drain into a suitable container and be inspected for metal particles or discoloration, which indicate wear inside the planetary gearbox.[7][4][6]

Industrial planetary gearbox manuals often call for replacing O‑rings or seals on drain plugs once the unit is reassembled, so these sealing components should be checked and discarded if damaged. After draining, the planetary gearbox exterior can be wiped down to remove dirt and oil so that bolts, alignment marks, and part numbers are easy to see.[9][4][6]

Once the oil is drained, the mounting hardware that secures the planetary gearbox to the mixer frame or mounting plate can be removed in a cross pattern to avoid binding. Service manuals for planetary gearbox spindle drives stress the need for safe lifting, so a hoist or jack is used to support the planetary gearbox weight as the last bolts are loosened.[1][4][6]

When the planetary gearbox is detached, it is carefully lowered to a workbench or stand, keeping the orientation consistent with reference marks so it can be reinstalled without confusion. On some mixer designs, the motor and planetary gearbox are integrated, so both assemblies are removed together and later separated as part of the disassembly process.[4][6][9][1]

Before splitting the housing, many planetary gearbox manuals recommend scribing a diagonal line across the cover and base to preserve alignment for reassembly. Then the perimeter bolts that clamp the planetary gearbox housing together are removed in stages, usually in a crisscross pattern to relieve stress evenly.[8][6][4]

With the bolts removed, the cover of the planetary gearbox can be lifted straight up using threaded lifting holes or pry points provided by the manufacturer, taking care not to damage the machined surfaces. Gasket material or O‑rings between the cover and base should be inspected as the housing opens because these seals will typically be replaced after the planetary gearbox is serviced.[6][7][4]

Inside a multi‑stage planetary gearbox, service manuals describe a sequence that starts by lifting out the upper planet carrier assembly as a complete unit, including the carrier, planet gears, shafts, washers, and bearings. After removing the carrier, the ring gear is taken out, and technicians inspect O‑rings on the outer perimeter and thrust washers supporting the carrier.[4][6]

The process repeats for lower stages of the planetary gearbox, where the secondary planet carrier assembly and secondary ring gear are removed in order, creating groups of parts that correspond to separate gear stages. Throughout this process, the sun gear and output shaft may remain in the base until the final stage is disassembled, depending on the particular planetary gearbox layout.[7][6][4]

With the carrier assemblies out of the planetary gearbox housing, the next step is to disassemble the planet gears from the carriers for detailed inspection. Manuals instruct technicians to drive roll pins into the planet shafts, press or drive the shafts out of the carrier, and then remove the planet gears, washers, and roller bearings.[6][4]

Each planet gear in the planetary gearbox is checked for abnormal wear patterns, pitting, scoring, or bearing failure, and the corresponding planet shafts are inspected for wear and deformation. If bearings or gears show damage, the manual typically recommends replacement, followed by careful reassembly of the planet gear, washers, and bearings into the carrier using the reverse sequence.[7][4][6]

After the planet carriers and gears are removed, attention turns to the bearings and seals that support the output shaft and intermediate elements of the planetary gearbox. Service manuals explain how to remove lock rings, split rings, and shims that hold the bearings in place, followed by pressing the bearings off the shaft and inspecting them for wear or damage.[4][6][7]

The shaft seal surfaces inside the planetary gearbox are also checked for scoring or corrosion, and any lip seals or O‑rings on the output shaft area are replaced as part of standard service. Proper inspection and replacement of these components are critical to keeping oil inside the planetary gearbox and preventing contamination from entering.[8][4]

Disassembly instructions for mixer planetary drives emphasize cleaning each component with suitable solvents and drying them thoroughly before measurement and reassembly. Components such as gears, carriers, and housings from the planetary gearbox should be kept free of lint and dirt, particularly in bearing bores and sealing surfaces.[6][4]

It is also important to document the planetary gearbox disassembly with notes, tags, or photos showing the order of parts and their original orientation, especially when similar carriers and ring gears are stacked in multiple stages. Clear documentation reduces the risk of mis‑stacking parts and ensures that the Laird mixer planetary gearbox operates as designed once reassembled.[3][4][6]

Professional planetary gearbox service procedures include measuring critical dimensions such as gear tooth thickness, bearing internal clearance, and shaft runout using calipers or micrometers. By comparing these measurements with allowable limits in the planetary gearbox service manual, technicians can decide whether parts must be reused, repaired, or replaced.[7][4][6]

Backlash in a planetary gearbox is another important parameter, and excessive backlash can indicate worn sun gears, planet gears, or ring gear teeth in mixer drives. Keeping the planetary gearbox within the recommended tolerances helps reduce noise, shock loads, and uneven torque distribution in the mixer application.[4][6][7]

Even though the focus is on how to take apart a Laird mixer planetary gearbox, reassembly must be planned from the start. Service manuals for planetary gearbox drives show that carriers, ring gears, and sun gears must be reinstalled in a specific sequence with correct torque settings and shim adjustments.[6][7][4]

Fresh lubricant of the specified grade and viscosity must be added to the planetary gearbox after reassembly, and oil levels are checked according to the mixer manufacturer's instructions. After the planetary gearbox is mounted back on the mixer and connected to the drive, the machine is test‑run under light load to verify proper operation, noise level, and oil tightness.[2][1][8]

Because planetary gearbox disassembly involves many small parts and stages, visual references greatly improve understanding and reduce mistakes. Many maintenance teams create illustrated step‑by‑step guides for their own Laird mixer planetary gearbox models based on the official service procedure, showing each carrier, ring gear, and bearing group.[5][3][9][4]

Online, several high‑rigidity planetary gearbox disassembly demonstrations and mixer planetary drive service walkthroughs are available as streaming clips or short training media. These clips typically show the complete process of removing the planetary gearbox, opening the housing, extracting carriers, and inspecting gears, which can be used as training material for technicians.[10][11][5]

Laird mixer systems and similar vertical mixers rely on heavy‑duty planetary gearbox designs because they deliver high torque density, compact size, and robust reliability in dusty, high‑shock environments. The planetary gearbox architecture, with multiple planet gears sharing the load inside a ring gear, allows the mixer to handle challenging rations without over‑stressing a single gear mesh.[5][1][4]

Manufacturers of planetary gearbox drives for mixers often highlight long service intervals, low operating temperatures, and simplified maintenance as key advantages for feedlot and agricultural operators. When combined with quality hydraulic motors or PTO drives, a well‑maintained planetary gearbox gives the mixer a long, cost‑effective service life.[1][4][6]

To avoid unplanned disassembly, operators are advised to follow the lubrication intervals and oil level checks recommended in the mixer and planetary gearbox manuals. Regular inspection of seals, breather caps, and temperature behavior can reveal early signs of planetary gearbox problems such as overheating, oil leaks, or contamination.[2][8][4][6]

For heavy‑duty use, some planetary gearbox service manuals recommend periodic partial disassembly to inspect critical gears and bearings at defined hour intervals. If abnormal wear, pitting, or spalling is discovered, early corrective action can be taken before catastrophic failure occurs inside the planetary gearbox.[7][4][6]

Service documents for planetary gearbox drives frequently warn against prying directly on bearing cages or sealing surfaces, which can cause damage and lead to premature failures. Another common error is mixing parts from different planetary gearbox stages or failing to mark the orientation of carriers and ring gears, which can introduce misalignment or assembly errors.[4][6][7]

Technicians may also underestimate the lifting requirements of a large mixer planetary gearbox, attempting to remove the casing without adequate hoisting equipment. This not only increases the risk of personal injury but can also distort or crack the planetary gearbox housing if it is allowed to fall or hang unevenly.[8][6][4]

When planning to take apart a Laird mixer planetary gearbox, it is wise to obtain the correct OEM service manual or exploded view drawing for the specific mixer model. These documents show part numbers, torque values, shim stacks, and specific disassembly instructions that might differ slightly from generic planetary gearbox procedures.[1][6][4]

In addition, many gearbox and mixer manufacturers offer technical support, training, and original replacement parts kits that include seals, bearings, and hardware matched to the planetary gearbox. Using factory‑approved components helps preserve the designed performance, durability, and warranty status of the planetary gearbox on the mixer.[2][1][4]

Taking apart a Laird mixer planetary gearbox is a structured, multi‑stage process that begins with strict safety precautions and careful removal of the unit from the mixer. Once the planetary gearbox is drained and opened, technicians remove ring gears, carriers, and planet gears in sequence, documenting orientation and inspecting every part for wear before reassembly.[3][2][6][4]

A planetary gearbox offers compact, high‑torque performance for demanding mixer applications, but it must be disassembled, cleaned, and inspected according to professional service procedures to maintain reliability. By following manufacturer guidelines, using proper lifting equipment, and paying attention to details such as seals, bearings, and alignment marks, operators can service their planetary gearbox safely and extend the life of their Laird mixer drive system.[1][4]

Service intervals for a Laird mixer planetary gearbox depend on operating hours, load, and environmental conditions, but many planetary gearbox service manuals suggest inspection at defined hour thresholds such as 1,000 hours for heavy‑duty drives. Operators should also refer to the mixer manufacturer's maintenance schedule, which specifies lubrication and inspection intervals for the planetary gearbox based on typical feedlot use.[2][1][6][4]

For smaller units, some partial service operations such as oil changes or seal replacement can sometimes be performed with the planetary gearbox still mounted, but full disassembly generally requires removal to a bench. Laird mixer systems use heavy planetary gearbox assemblies that are easier and safer to open, clean, and reassemble when they are properly supported off the machine.[1][6][4]

Lubricant selection for a mixer planetary gearbox is specified by the equipment manufacturer and usually involves high‑quality gear oil of a particular viscosity and performance grade suitable for heavy loads. Using the wrong oil in a planetary gearbox can lead to overheating, inadequate film strength, or foaming, so operators should follow the exact recommendation in the Laird mixer documentation.[8][2][1]

Early signs of wear inside a planetary gearbox include increased noise, vibration, temperature rise, and metallic particles in the drained oil captured on magnetic plugs. Routine oil analysis and regular visual inspection of seals and housings for leaks help detect problems in the planetary gearbox before major failure occurs.[6][7][4]

Laird offers multiple mixer series, and the drive system specification, including the planetary gearbox size and configuration, can vary with capacity and application. While the general planetary gearbox principles of sun gear, planet gears, and ring gear remain consistent, each mixer model may have specific mounting, lubrication, and service details that are outlined in the corresponding manual.[1][4]

[1](https://lairdmanufacturing.com/equipment-overview/vt-series/)

[2](https://morline.com/wp-content/uploads/2020/08/VR-Vertical-Traile-2-SPD.pdf)

[3](https://manufacturer.hzpt.com/how-to-take-apart-a-laird-mixer-planetary-gearbox-16/)

[4](https://www.eskridgeinc.com/wp-content/uploads/2018/07/440-Gear-Drive-Service-Manual.pdf)

[5](https://www.youtube.com/watch?v=PCeF2ir31BA)

[6](https://www.gsglobalresources.com/uploads/Eskridge_252_SpindleDrive_ServiceManual.pdf)

[7](https://eskridgeinc.net/wp-content/uploads/2018/08/252L-Spindle-Gear-Drive-Service-Manual.pdf)

[8](https://download.sew-eurodrive.com/download/pdf/27805379.pdf)

[9](https://www.ifixit.com/Guide/How+to+service+the+planetary+drive+in+your+mixer/198644)

[10](https://www.youtube.com/watch?v=GWWU9OlCVQY)

[11](https://www.tiktok.com/@huatao_gearbox_official/video/7503912261723966766)