Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is a Planetary Gearbox?

● Core Advantages of a Planetary Gearbox

>> High efficiency and low backlash

>> Flexible ratios and multi-stage options

● When to Use a Planetary Gearbox?

>> Space and weight are limited

>> High torque and high reduction ratio are needed

>> Loads are heavy, shock-prone, or intermittent

>> Precision and stiffness are important

>> Coaxial layout and flexible mounting are required

● Typical Applications of a Planetary Gearbox

>> Mobile machinery and tracked equipment

>> Industrial automation and robotics

>> Renewable energy and power transmission

>> Medical, aerospace, and precision devices

● Planetary Gearbox vs Helical Gearbox

● Selection Considerations for a Planetary Gearbox

>> Torque, speed, and duty cycle

● When a Planetary Gearbox Is Not the Best Choice

● Summary of When to Use a Planetary Gearbox

● FAQ About When to Use a Planetary Gearbox

>> FAQ 1: When is a planetary gearbox better than a helical gearbox?

>> FAQ 2: Can a planetary gearbox handle shock loads and heavy-duty cycles?

>> FAQ 3: Is a planetary gearbox suitable for precision servo and robotics applications?

>> FAQ 4: When should I choose a multi-stage planetary gearbox?

>> FAQ 5: How do environmental conditions affect planetary gearbox selection?

A planetary gearbox is the right choice whenever a machine needs very high torque, compact dimensions, high efficiency, and precise motion control under demanding working conditions. In mobile machinery, industrial automation, robotics, medical equipment, and renewable energy, a planetary gearbox often outperforms traditional helical or spur gearboxes because it delivers more power in less space with excellent load sharing and stiffness.[1]

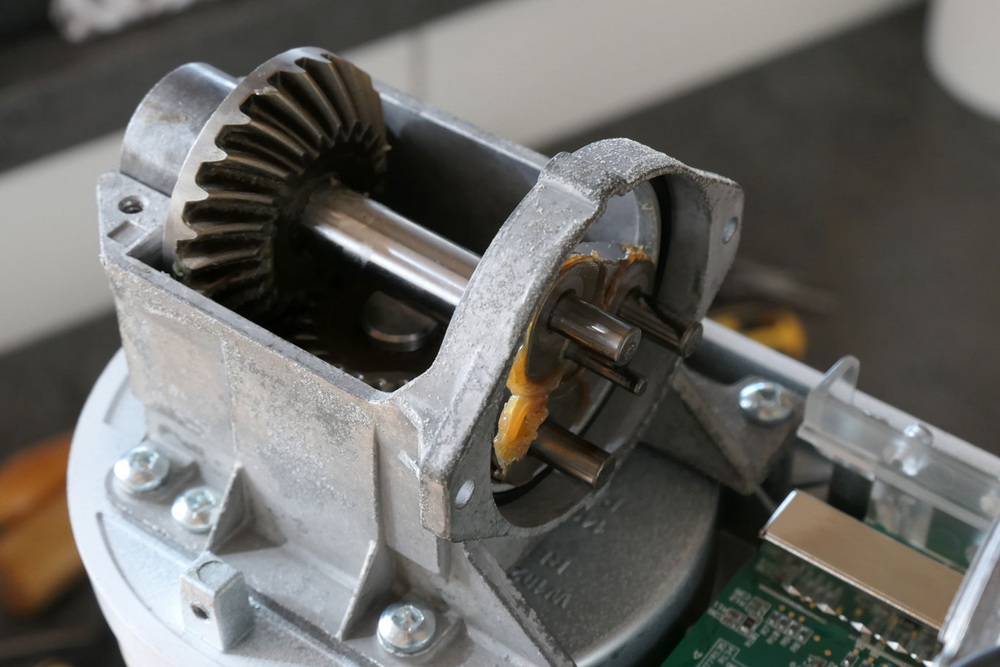

A planetary gearbox is a gear reducer that uses a central sun gear, multiple planet gears, and an outer ring gear to transmit power while reducing speed and increasing torque. This coaxial structure lets the planetary gearbox share load across several planet gears, which is why the planetary gearbox can handle higher torque than a similarly sized parallel-shaft or helical gearbox.[1]

In a standard planetary gearbox, the input shaft usually drives the sun gear, the planet gears rotate around it on a carrier, and the ring gear either remains fixed or becomes the output, depending on the configuration. Because the planetary gearbox has multiple gear meshes in contact at the same time, it achieves high efficiency, low backlash, and smooth operation even at high loads.[2][1]

To serve different markets, many manufacturers configure the planetary gearbox into travel drives, winch drives, swing drives, and integrated hydraulic motor solutions for tracked undercarriages and lifting systems. This modular approach allows one planetary gearbox platform to cover diverse ratios, mounting interfaces, and torque ranges for global customers in construction, mining, and industrial equipment.[3]

A planetary gearbox is not just another reducer; it is chosen because its internal geometry creates unique performance advantages. When engineers understand these advantages, it becomes clear exactly when to use a planetary gearbox and when another gearbox type may be sufficient.[3][1]

A planetary gearbox spreads load across several planet gears, so the planetary gearbox can transmit very high torque in a compact, relatively light housing. This high torque-to-volume ratio makes the planetary gearbox ideal where space and weight are limited but heavy-duty work is required, such as tracked undercarriages, winch drives, and swing drives.[1][3]

The input and output of a planetary gearbox are typically aligned on the same axis, which simplifies machine layout and reduces installation space. For compact equipment like crawler tracks, boom rotation systems, or robot joints, the short overall length of a planetary gearbox is a major benefit compared with offset gear arrangements.[2][1]

Because several teeth are in mesh at the same time, a planetary gearbox usually achieves efficiency above 95% when properly designed and lubricated. At the same time, a precision planetary gearbox offers low backlash and high torsional stiffness, which are essential for accurate positioning and fast dynamic response in servo applications.[4][1]

The multiple meshing paths in a planetary gearbox distribute forces and can reduce vibration compared with simple spur gear trains. With proper tooth geometry and quality manufacturing, the planetary gearbox can operate smoothly and quietly even at high speed and under variable loads.[5][1]

Designers can stack multiple planetary gearbox stages to achieve very high total reduction ratios while still keeping a compact footprint. This multi-stage planetary gearbox design is common in winch drives, slewing drives, and travel drives where slow, powerful rotation is required from a relatively fast motor.[3][1]

The planetary gearbox becomes the preferred choice whenever an application needs a combination of high torque, compact size, high efficiency, and precise motion. The decision to use a planetary gearbox instead of a helical or spur gearbox is strongly linked to torque density, installation space, duty cycle, and control accuracy.[6][1]

Engineers should use a planetary gearbox when machine layout is tight and every millimeter of space matters. In mobile machinery, lifting platforms, compact industrial equipment, and battery-powered vehicles, a planetary gearbox provides strong torque in a very small envelope that would be difficult to match with a helical gearbox.[3]

A planetary gearbox is ideal when a drive system must produce high output torque at low speed from a relatively small motor. Single- and multi-stage planetary gearbox designs allow engineers to achieve high reduction ratios without long shafts or large-diameter gears, making them perfect for winches, slewing rings, and crawler drives.[1][3]

Because torque is shared across multiple planet gears, a planetary gearbox handles shock loads and peak loads more effectively than some single-path gear trains. This makes a planetary gearbox suitable for cranes, drilling rigs, mining machines, and construction equipment where sudden impacts and overloads are common.[7][8]

In servo axes, robotics, and machine tools, it is essential to keep backlash low and stiffness high so that the output follows motor commands accurately. A precision planetary gearbox is widely used here because its compact design and multiple gear meshes provide the rigidity and repeatability required in demanding positioning tasks.[4]

Many applications require the input motor and output shaft to be aligned on the same axis, either for geometric reasons or for load distribution. A planetary gearbox naturally meets this requirement, and modern planetary gearbox designs are available with flange mounts, shaft outputs, and integrated motor adaptors to simplify installation.[2][1]

The planetary gearbox appears in almost every industry segment where high torque and compactness are critical. From heavy mobile equipment to high-precision medical devices, the planetary gearbox provides a reliable and efficient way to control speed and torque.[1][3]

In mobile machinery, a planetary gearbox is often integrated into travel drives for tracked undercarriages. Crawler excavators, drilling rigs, and crawler cranes rely on planetary gearbox travel drives that combine a hydraulic or electric motor with a multi-stage planetary gearbox to provide strong tractive effort in a compact module.[9][3]

Winch drives on cranes, tow trucks, and offshore handling systems frequently use a planetary gearbox to obtain very high line pull from modest input power. The planetary gearbox provides both the reduction ratio and the torque capacity needed to lift and hold heavy loads while keeping the drum assembly relatively small.[8][3]

Swing drives or slewing drives that rotate an upper structure around a vertical axis also benefit from a planetary gearbox. The swing planetary gearbox delivers smooth rotation, high holding torque, and fine control, which is essential for safe and accurate positioning of booms and superstructures.[8][3]

In industrial automation, a planetary gearbox is commonly installed on servo motors that drive robot arms, gantry axes, and indexing tables. The low backlash and high torsional stiffness of a precision planetary gearbox ensure accurate motion and repeatable positioning over millions of cycles.[4]

Automated storage systems, panel handling lines, and conveyor systems use a planetary gearbox when they need strong torque in limited space. In these systems, a planetary gearbox provides efficient, continuous operation and integrates easily with standard motor flanges and couplings.[1]

In wind turbines, a planetary gearbox is often part of yaw and pitch drives that slowly rotate the nacelle and adjust blade angles. These systems demand high torque at low speed with compact components, and a planetary gearbox is well suited to operate reliably under varying and sometimes turbulent loads.[10][8]

Advanced power transmission systems, such as hybrid vehicle drivetrains, use a planetary gearbox as a power-splitting device. By controlling which elements of the planetary gearbox are driven, held, or braked, designers can blend torque from internal combustion engines and electric motors in a very compact package.[11][2]

In medical equipment, a miniaturized planetary gearbox is used in surgical robots, imaging systems, and patient handling devices where precise, smooth motion is essential. The quiet operation and high efficiency of a planetary gearbox support both patient comfort and long-term reliability.[7][1]

Aerospace actuators and satellite positioning mechanisms often rely on a planetary gearbox for high power density and reliability under extreme environmental conditions. In these systems, the planetary gearbox provides very accurate, small-angle motion while withstanding wide temperature ranges and severe vibration.[11][2]

In smaller consumer and professional devices such as power tools and camera drives, a compact planetary gearbox helps deliver strong torque from a small motor. The planetary gearbox in these devices improves durability, efficiency, and control feel for the user.[12][5]

Many engineers must decide between a planetary gearbox and a helical gearbox for high-torque drives. Both are proven technologies, but each gearbox type suits different priorities in torque, size, noise, cost, and maintenance.[13][6]

A planetary gearbox offers very high torque density, compact size, and the potential for low backlash and high stiffness, which makes it ideal for mobile machinery, robotics, and servo drives. A helical gearbox, however, may be more economical in applications with ample space, moderate loads, and less demanding precision requirements, such as standard conveyors or fans.[13][1]

A planetary gearbox may require higher initial investment and more careful lubrication management, especially in multi-stage designs. A helical gearbox often has simpler construction and may allow longer lubrication intervals, which can be attractive in cost-sensitive applications where performance margins are not pushed to the limit.[14][6]

When choosing between them, engineers should compare torque demand, radial and axial loads, expected shock factors, installation space, precision needs, and life-cycle cost. Whenever compact size, high torque, and accurate control matter more than the lowest possible purchase price, a planetary gearbox is usually the better option.[6][14]

Selecting the right planetary gearbox involves more than picking a ratio from a catalogue; it requires understanding load, duty cycle, environment, and integration with the motor and machine. Careful definition of these parameters allows engineers to specify a planetary gearbox that will run reliably for its expected service life.[9][3]

The rated torque of a planetary gearbox must exceed the maximum operating torque, including start-up, acceleration, and shock peaks. Engineers should consider continuous torque, peak torque, and service factors to choose a planetary gearbox size that avoids overload and premature wear.[8][3]

Input speed and desired output speed define the required reduction ratio of the planetary gearbox. The duty cycle—such as intermittent, frequent start-stop, or continuous operation—also affects the thermal capacity of the planetary gearbox and may require derating or improved cooling.[3][1]

The output shaft or flange of a planetary gearbox often carries significant radial or axial loads from gears, sprockets, pulleys, or drums. Correctly evaluating these loads is essential to ensure that the bearings inside the planetary gearbox can provide sufficient life.[3][1]

If loads are very high, a planetary gearbox with reinforced bearings, stronger housing, or external bearing supports may be necessary. Neglecting these aspects can lead to premature bearing failure even if the torque rating of the planetary gearbox is adequate.[9][3]

Environmental conditions such as dust, mud, moisture, salt spray, and chemicals directly influence sealing and material choice for a planetary gearbox. For harsh outdoor or offshore environments, the planetary gearbox should have appropriate protection class, corrosion-resistant coatings, and seals suited to the contaminants present.[5][3]

Temperature extremes affect lubricant viscosity and the material properties of gears and seals inside the planetary gearbox. High ambient temperatures may require high-temperature oils or special synthetic lubricants, while very low temperatures may demand low-viscosity fluids so that the planetary gearbox starts easily.[5]

A planetary gearbox can usually be mounted in various orientations, but the lubricant level, breather location, and sealing concept must be compatible with the chosen position. Correct alignment between the motor and planetary gearbox is essential to avoid bearing overload, noise, and vibration.[1]

Modern planetary gearbox designs often offer direct motor adapters, integrated couplings, and multiple output options such as solid shafts, hollow shafts, or flanges. These options make it easier to integrate a planetary gearbox into different machines without complex custom brackets or couplings.[9][1]

Although a planetary gearbox has many strengths, there are situations where another gearbox type can be more suitable. Understanding these limitations helps engineers make balanced decisions and optimize cost and performance.[14][6]

If the application has low to moderate torque, plenty of space, and relatively steady loads, a helical gearbox or even a simple spur gear solution may be more economical. In such cases, the higher cost and complexity of a planetary gearbox may not bring enough benefit to justify the investment.[13][14]

Where extremely low noise is the dominant requirement and torque density is less critical, a well-designed helical gearbox can sometimes deliver quieter operation than a standard planetary gearbox. Also, in very low-ratio applications where only a small speed reduction is needed, a planetary gearbox may not provide a clear advantage over simpler gear trains.[13]

In practical terms, engineers should use a planetary gearbox when they need:

- Very high torque from a compact drive package.

- High reduction ratios in limited space, especially with multi-stage units.

- High efficiency, low backlash, and good torsional stiffness for precise control.

- Robust performance under shock loads, heavy-duty cycles, and harsh environments.

- Coaxial layout and flexible mounting for integration with motors and machine structures.

When these conditions are present, a planetary gearbox provides clear technical and commercial advantages over many alternative gearbox types. Correct selection and integration ensure that the planetary gearbox delivers long, reliable service in demanding industrial and mobile applications.[3][1]

A planetary gearbox is the preferred solution when a drive system must deliver high torque, high efficiency, and precise motion within a compact, lightweight package. From mobile machinery travel drives and winch drives to high-precision robotics, medical equipment, and renewable energy systems, the planetary gearbox offers a unique combination of torque density, stiffness, and flexibility that traditional gearboxes struggle to match. By carefully defining torque, speed, duty cycle, environment, and precision requirements, engineers can confidently decide when to use a planetary gearbox and work with specialized manufacturers to specify the right planetary gearbox configuration for demanding global applications.[9][1][3]

A planetary gearbox is better than a helical gearbox when the application requires very high torque in a limited space, such as mobile equipment, robotics, or compact servo axes. The planetary gearbox provides higher torque density, better stiffness, and more compact dimensions, while a helical gearbox is usually chosen where space is available and lower cost is more important than maximum performance.[6][13]

Yes, a planetary gearbox is well suited for shock loads and heavy-duty operation because multiple planet gears share the torque and reduce stress on individual teeth. This makes the planetary gearbox an excellent choice for winch drives, travel drives, swing drives, and other construction or mining machinery working under highly variable and demanding loads.[7][8]

A precision planetary gearbox is widely used for servo and robotics applications because it offers low backlash, high torsional stiffness, and high efficiency. These properties allow the planetary gearbox to deliver accurate positioning, fast dynamic response, and repeatable performance in robot arms, pick-and-place systems, and CNC machine axes.[4]

Choose a multi-stage planetary gearbox when the required speed reduction is very high but the available space is still limited and output torque must remain high. By stacking two or more stages, the planetary gearbox can reach large total ratios for slow, powerful outputs, which is ideal for winches, slewing drives, and crawler travel drives powered by relatively fast motors.[1][3]

Environmental conditions such as dust, moisture, temperature, and chemical exposure directly influence sealing, lubrication, and material choices for a planetary gearbox. For harsh outdoor, marine, or offshore environments, the planetary gearbox should have suitable protection class, corrosion-resistant materials, and lubricants specified for the expected temperature and contamination levels to ensure long, reliable service.[5][3]

[1](https://www.sesamemotor.com/blog_detail/en/planetary-gearboxes-advantages)

[2](https://www.machinedesign.com/mechanical-motion-systems/article/21834331/planetary-gears-the-basics)

[3](https://kavitsu.com/in-what-applications-are-planetary-gearboxes-commonly-used-and-why.php)

[4](https://www.linearmotiontips.com/why-are-planetary-gearboxes-preferred-for-servo-applications/)

[5](https://www.zwgearbox.com/blog/advantages-of-planetary-gear-motors)

[6](https://www.sgrgear.com/news/industry-news/planetary-gearbox-vs-helical-gearbox-comprehensive-comparison.html)

[7](https://assunmotor.com/blog/planetary-gearbox/)

[8](https://www.santramengineers.com/the-role-of-planetary-gearboxes-in-high-torque-applications/)

[9](https://thmhuade.com/high-torque-planetary-gearbox-applications-gft-track-gearbox/)

[10](https://www.iqsdirectory.com/articles/gear/planetary-gears.html)

[11](https://www.metmo.co.uk/blogs/news/planetary-gears-explained-a-design-written-in-the-stars)

[12](https://www.michiganmech.com/blog/what-are-the-advantages-of-using-planetary-gears-in-power-tools/)

[13](https://www.wumareducer.com/What-is-the-difference-between-planetary-gearbox-and-helical-gearbox-id44668566.html)

[14](https://www.guomaolide.com/2025/12/04/planetary-gearbox-vs-helical-gearbox-which-is-right-for-your-project/)