Views: 222 Author: Robert Publish Time: 2026-01-17 Origin: Site

Content Menu

● From Hand Cranks to Early Mechanical Winches

● The Birth of the Dedicated Tow Truck

● Why Manual and Mechanical Winches Had Limits

● The Rise of Hydraulic Power in the 1950s–1960s

● From Hook‑and‑Chain to Hydraulic Wheel‑Lift and Flatbeds

● The Hydraulic Revolution of the 1970s–1980s

● How a Hydraulic Winch Changed Tow Truck Performance

● Key Components of Modern Hydraulic Winch Tow Trucks

● Hydraulic Winch Advantages Over Manual Systems

● Hydraulic Winch Tow Trucks in Today's Market

● Future Trends in Hydraulic Winch Tow Trucks

● More Ways Hydraulic Winches Improved Towing

● Hydraulic Winch Integration with Chassis and PTO

● Hydraulic Winch Maintenance and Reliability

● Hydraulic Winch Safety Practices in Real Operations

● Hydraulic Winch Applications Beyond Roadside Towing

● How Kemer Solutions Enhance Hydraulic Winch Systems

● Choosing the Right Hydraulic Winch Configuration

● FAQ About Manual and Hydraulic Winch Tow Trucks

>> 1. When did tow trucks start using hydraulic winches?

>> 2. Why are hydraulic winches better than manual winches on tow trucks?

>> 3. Can modern tow trucks still use non‑hydraulic winches?

>> 4. What components are needed for a tow‑truck hydraulic winch system?

>> 5. How does a manufacturer like Kemer support hydraulic winch tow trucks?

Tow trucks moved from fully manual winches to hydraulically powered lifting and recovery systems mainly between the 1950s and the early 1980s, as hydraulic winch and lift technology spread through the towing industry. This hydraulic revolution transformed tow trucks from simple hook‑and‑chain wreckers into powerful, precise recovery vehicles with modern hydraulic winch systems.

Early tow trucks in the 1910s and 1920s used simple mechanical winches based on hand cranks, pulleys, and chains to recover vehicles after breakdowns or accidents. These early systems required significant manual effort, so a tow operator often relied on muscle power plus simple gearing rather than any hydraulic winch technology.

As the number of cars on the road increased, tow trucks evolved to include gear‑driven winches powered mechanically from the truck's drivetrain via power‑take‑off (PTO) shafts. These PTO‑driven mechanical winches still depended on steel cables, booms, and pulleys, but they eliminated much of the manual cranking and became the standard recovery solution long before the first hydraulic winch appeared on wreckers.

In 1916, Ernest Holmes Sr. in Chattanooga, Tennessee, built what is widely recognized as the first dedicated tow truck by mounting a crane, pulley, and winch system onto a car chassis. This innovation introduced a practical, truck‑mounted winch package that paved the way for later hydraulic winch and hydraulic boom systems on professional wreckers.

Holmes' early wreckers used split‑boom structures, outriggers, and cable‑driven mechanical winches designed to pull vehicles from ditches or lift one end for towing. Over the following decades, these mechanical tow trucks dominated the market, and tow operators refined techniques for rigging, anchoring, and controlling loads with purely mechanical winches rather than any hydraulic winch system.

Mechanical and manual winches on early tow trucks had several serious limitations in terms of safety, control, and lifting power. Operators had to manage heavy loads with relatively crude brake and clutch systems, and a sudden shock load or cable failure could easily damage equipment or injure workers, especially without the smooth torque control later provided by a hydraulic winch.

These early winches also struggled with very heavy commercial vehicles, buses, and later high‑value cars that required more precise, damage‑free handling. As cars became heavier and more expensive, towing companies needed more powerful lifting systems and better load control, which set the stage for hydraulic winch technology to replace manual and purely mechanical systems.

By the 1950s, hydraulic lifting systems began to appear on tow trucks and other recovery equipment, allowing operators to raise vehicles more precisely and with less effort. Instead of relying only on mechanical gearing, tow trucks used hydraulic cylinders and hydraulic winch drives powered by pressurized oil from engine‑driven pumps.

Hydraulic systems offered smoother, more controllable lifting motion, which made it possible to recover vehicles from tight or difficult locations without adding more damage. This period marks the beginning of the transition from manual and mechanical winches to hydraulic winch‑based tow trucks, particularly in heavy‑duty recovery and professional fleet operations.

For decades, hook‑and‑chain tow trucks dominated the industry, lifting vehicles by their frames or axles using chains and a boom winch. While effective, this method often damaged bumpers and frames, so even as hydraulic winch systems spread, towing professionals looked for less damaging lifting methods.

During the 1960s–1980s, hydraulic wheel‑lift systems and hydraulic flatbeds were introduced, using hydraulic arms, yokes, and platforms instead of simple chains. These systems combined hydraulic cylinders and, in many cases, hydraulic winch drives to control lifting, tilting, and pulling operations, marking a clear shift away from purely manual and mechanical winches on modern tow trucks.

Industry historians often describe the 1970s and early 1980s as a hydraulic revolution for tow trucks, when hydraulics took over core lifting and winching functions. Manufacturers introduced advanced wreckers with hydraulic under‑lifts, hydraulic booms, and integrated hydraulic winch packages driven by PTO‑powered hydraulic pumps.

A major milestone in this era was the introduction of fully hydraulic under‑lift wreckers, which provided highly controlled lifting and towing without the limitations of older mechanical systems. At the same time, hydraulic rotators and 360‑degree recovery trucks emerged, combining large hydraulic winch units, slewing drives, and hydraulic cylinders to handle complex heavy‑recovery tasks.

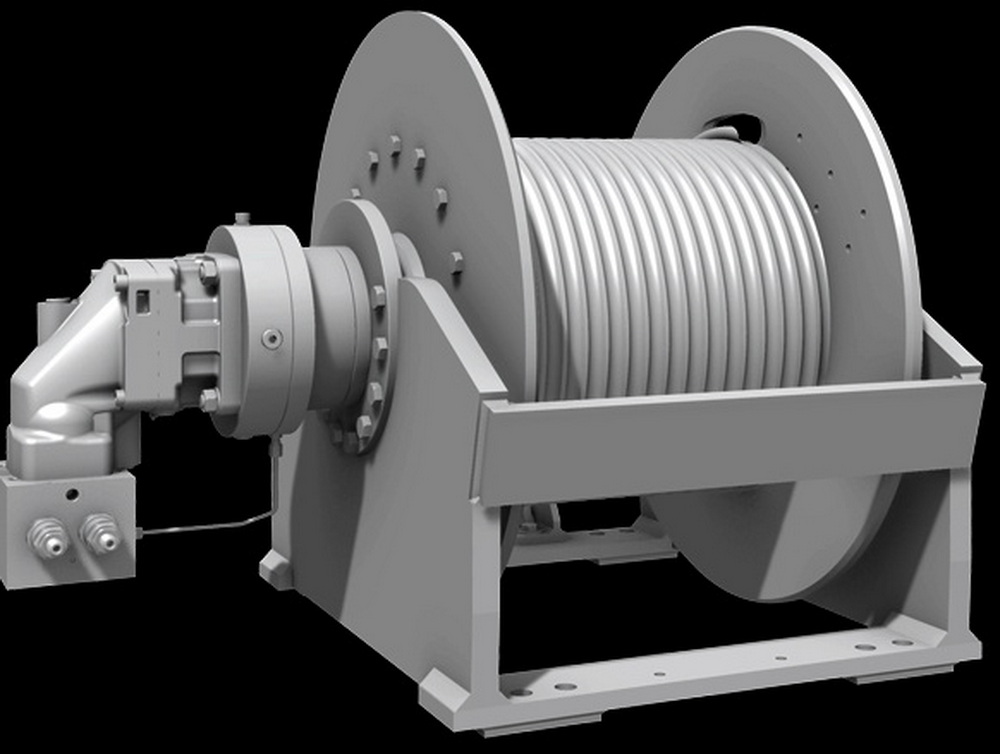

A hydraulic winch uses pressurized hydraulic fluid to drive a high‑torque hydraulic motor, which then turns a drum to wind or unwind the towing cable. When installed on a tow truck, a hydraulic winch can pull heavy loads at low speed with very fine control, and the operator can modulate pressure or flow to match the recovery situation.

Compared with manual or purely mechanical units, a hydraulic winch delivers much higher pulling capacity, longer duty cycles, and smoother operation under shock loads. With the right planetary gearbox and braking system, a hydraulic winch can manage continuous industrial work, making it ideal for modern heavy‑duty wreckers, rotators, and recovery vehicles.

Modern tow trucks integrate entire hydraulic systems around the hydraulic winch, not just a single pump or motor. Typical components include hydraulic pumps driven by engine PTO, directional control valves, pressure‑relief valves, hydraulic motors, planetary gearboxes, drum brakes, and control stations.

These components allow the hydraulic winch, hydraulic boom, and under‑lift arms to work together as a coordinated system for safe, precise vehicle recovery. For example, a tow operator can extend the boom, rotate a rotator, deploy stabilizers, and operate the hydraulic winch simultaneously, all managed through hydraulic controls and valves.

The shift from manual and mechanical units to the hydraulic winch on tow trucks brought multiple performance advantages. Key benefits include higher pulling forces, better low‑speed control, smoother starts and stops, reduced operator fatigue, and improved safety under high loads.

Hydraulic winch systems also support continuous, heavy‑duty operation because hydraulic oil carries heat away from the motor and allows higher duty cycles than many electric or manually assisted systems. In addition, hydraulic winch drives integrate easily with planetary gearboxes, winch drives, and swing drives from industrial suppliers such as Kemer, creating compact, robust recovery packages for modern tow fleets.

Today, most heavy‑duty and professional recovery trucks rely on one or more hydraulic winch units for core pulling and lifting tasks. These trucks often feature multiple hydraulic winch drums, high‑capacity planetary gearboxes, and sophisticated hydraulic circuits that support side pulls, multi‑line rigging, and complex recovery scenarios.

Suppliers such as Kemer manufacture hydraulic winch products, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors tailored for tracked undercarriages and mobile equipment, which can be integrated into modern tow and recovery platforms worldwide. By pairing a robust hydraulic winch with engineered gear and drive solutions, tow operators gain reliable performance in demanding industrial, construction, mining, and heavy‑transport environments.

Emerging trends include electronic control of hydraulic winch systems, remote‑control stations, and load‑sensing hydraulics that automatically adjust pressure and flow for safer operation. These technologies make it easier to manage complex recoveries while keeping operators at a safer distance from cables, hooks, and vehicle traffic.

There is also growing interest in hybrid solutions where a hydraulic winch works alongside electric or battery‑assisted systems, helping tow fleets reduce fuel consumption and emissions without sacrificing pulling power. In all of these designs, the hydraulic winch remains the central workhorse for heavy pulling, while digital controls and smarter hydraulics enhance precision and overall efficiency.

As hydraulic systems matured, tow truck builders began to add more specialized hydraulic winch configurations for different types of recovery work. Heavy‑duty wreckers might carry two or more hydraulic winch drums so operators can rig multi‑line pulls, side recoveries, or simultaneous front and rear anchoring.

Hydraulic winches also made it easier to introduce fold‑away booms, sliding decks, and under‑lift systems that could be controlled from a single operator station. With proportional hydraulic valves, the operator can feather the hydraulic winch speed, slow to a crawl near the final positioning of the casualty vehicle, and then lock the load with a reliable holding brake.

A key part of the evolution from manual to hydraulic winch systems was the integration of hydraulic power with the truck chassis. Instead of relying only on mechanical gearboxes, builders mounted hydraulic pumps directly to the engine or transmission using PTO outputs.

This arrangement allowed the engine to run at an efficient speed while the hydraulic winch received steady flow and pressure, delivering consistent torque at the drum. By choosing the right PTO ratio, pump displacement, and hydraulic winch motor size, engineers could optimize line speed and pulling force for different classes of tow trucks.

The move to hydraulic winch technology also changed maintenance practices for tow fleets. Operators had to monitor hydraulic oil cleanliness, temperature, and hose condition to keep the hydraulic winch working reliably under heavy loads.

Routine inspections include checking for leaks around fittings and seals, verifying that the hydraulic winch drum brake and load‑holding devices are functioning correctly, and confirming that the rope is spooled uniformly. When maintained properly, a hydraulic winch typically offers a very long service life, especially when paired with high‑quality planetary gearboxes and robust mounting structures.

Hydraulic winch systems offer excellent control, but safe operation still depends on correct procedures and training. Operators must calculate working load limits for the ropes, hooks, and shackles used with the hydraulic winch and avoid shock loading by starting pulls slowly.

It is also important to establish exclusion zones around the cable path so that no one stands in line with a loaded rope. Many fleets now add remote controls and cameras that allow operators to stand away from the hazard zone while still monitoring the hydraulic winch, the casualty vehicle, and surrounding traffic.

The same hydraulic winch technology that transformed tow trucks has also spread to construction, mining, marine, and forestry equipment. In these industries, a hydraulic winch often works with tracked undercarriages, swing drives, and travel drives to position heavy machinery or lift structural components.

For a manufacturer like Kemer, the tow‑truck segment is part of a broader family of hydraulic winch applications. By standardizing hydraulic motors, planetary gearboxes, and winch drums across multiple platforms, it becomes easier to offer custom hydraulic winch configurations that still share common parts and service procedures.

Kemer focuses on producing tracked chassis, hydraulic winches, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors for global customers. These components are engineered to work together, forming complete motion and lifting packages for tow trucks and other mobile machines.

By combining a Kemer hydraulic winch with matched planetary gearboxes and hydraulic motors, tow‑truck builders can optimize torque, speed, and durability. This integrated approach helps fleet owners reduce downtime, simplify maintenance, and ensure that the hydraulic winch system delivers reliable performance in challenging environments.

Selecting a hydraulic winch for a new tow truck involves balancing several technical factors. Engineers must consider maximum line pull, desired line speed, rope capacity, and the available hydraulic power on the chassis.

The hydraulic winch drum size and rope type influence how the tow operator will use the equipment in daily work, such as long‑distance recoveries, steep embankment pulls, or tight urban extractions. By working closely with hydraulic winch suppliers and drive manufacturers, tow‑truck builders can create configurations that match local regulations, typical vehicle weights, and the terrain where the truck will operate.

Tow trucks transitioned from manual and purely mechanical winches to hydraulically powered systems over several decades, with hydraulic lifting and winching becoming common from the 1950s onward and dominant by the 1970s–1980s. This shift delivered major gains in lifting power, controllability, safety, and efficiency, making the hydraulic winch the standard solution for modern towing and heavy‑recovery fleets.

Today's tow trucks integrate advanced hydraulic winch units, booms, and under‑lifts, supported by planetary gearboxes, hydraulic motors, and control valves, many sourced from specialized manufacturers such as Kemer for global industrial applications. As electronic controls, telematics, and hybrid powertrains evolve, the hydraulic winch will continue to sit at the core of professional towing technology, combining proven fluid power with smarter, more connected systems.

Tow trucks began adopting hydraulic lifting and winching systems in the 1950s, and hydraulics became widespread across professional wreckers during the 1970s and early 1980s. By that time, most heavy‑duty tow trucks had replaced manual and purely mechanical winches with at least one hydraulic winch for primary recovery work.

A hydraulic winch offers higher pulling capacity, smoother speed control, and longer duty cycles than manual or basic mechanical units, reducing operator fatigue and improving recovery speed. It also integrates easily with hydraulic booms and under‑lifts, giving tow‑truck operators precise control over both lifting and pulling operations in a single hydraulic system.

Some light‑duty or specialty recovery vehicles may use electric winches instead of a hydraulic winch, especially when hydraulic power is not available or loads are relatively low. However, most heavy‑duty and professional wreckers rely on hydraulic winch systems because they handle higher loads and continuous duty better than small electric or manual units.

A typical tow‑truck hydraulic winch system includes a hydraulic pump driven by the engine PTO, control valves, hydraulic hoses, a hydraulic motor, a planetary gearbox, a drum with wire rope or synthetic rope, and a brake. Additional components such as stabilizers, under‑lift arms, and rotator booms are often controlled by the same hydraulic circuit to create a fully integrated recovery platform.

Kemer provides hydraulic winch products, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors designed for tracked undercarriages and mobile machinery, which can be configured for tow and recovery vehicles worldwide. By supplying matched hydraulic winch and drive solutions, Kemer helps tow‑truck builders achieve reliable, high‑torque performance and long service life in demanding towing environments.