Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● Understanding Planetary Gearbox Design

● Core Reasons Planetary Gearbox Is Used

● High Torque Density And Load Capacity

● Compact Size And Coaxial Layout

● High Efficiency And Smooth Power Transmission

● Low Backlash And Precision Motion

● Flexible Gear Ratios And Configurations

● Durability In Harsh Working Conditions

● Typical Industrial Applications Of Planetary Gearbox

● Mobile Machinery And Off-Highway Uses

● Automotive And Transportation Uses

● Planetary Gearbox In Servo And Automation Systems

● How Planetary Gearbox Supports Kemer Solutions

● Maintenance And Reliability Considerations

● Economic Benefits Of Using Planetary Gearbox

>> 1. What is a planetary gearbox?

>> 2. Where is a planetary gearbox commonly used?

>> 3. How efficient is a planetary gearbox?

>> 4. Why choose a planetary gearbox instead of a traditional gearbox?

>> 5. How does a planetary gearbox support precision servo applications?

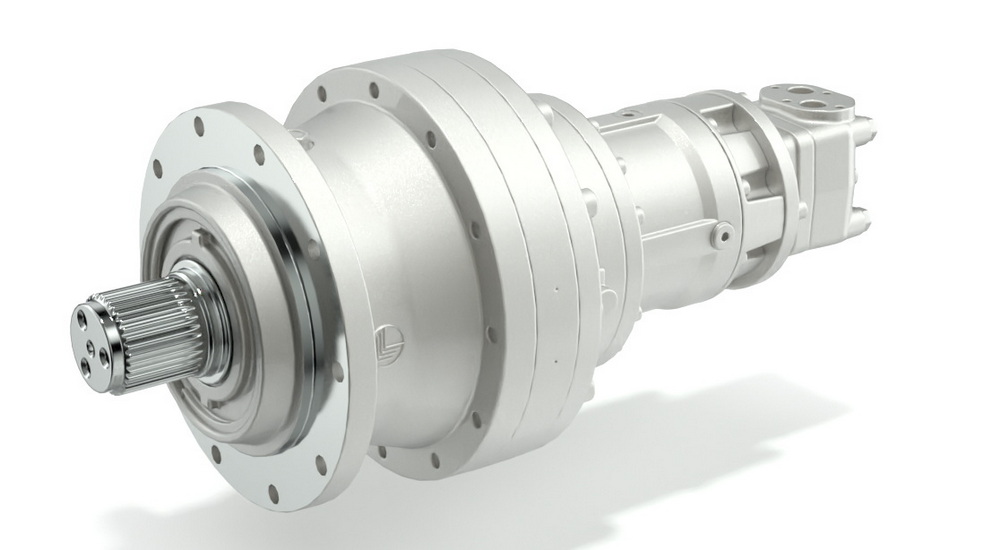

A planetary gearbox is used because it delivers extremely high torque in a compact, efficient package while maintaining smooth and precise power transmission under demanding working conditions. For manufacturers like Kemer, this makes the planetary gearbox a core technology in tracked chassis, travel drives, winch drives, swing drives, and hydraulic motor systems serving global construction, mining, and industrial customers.[1]

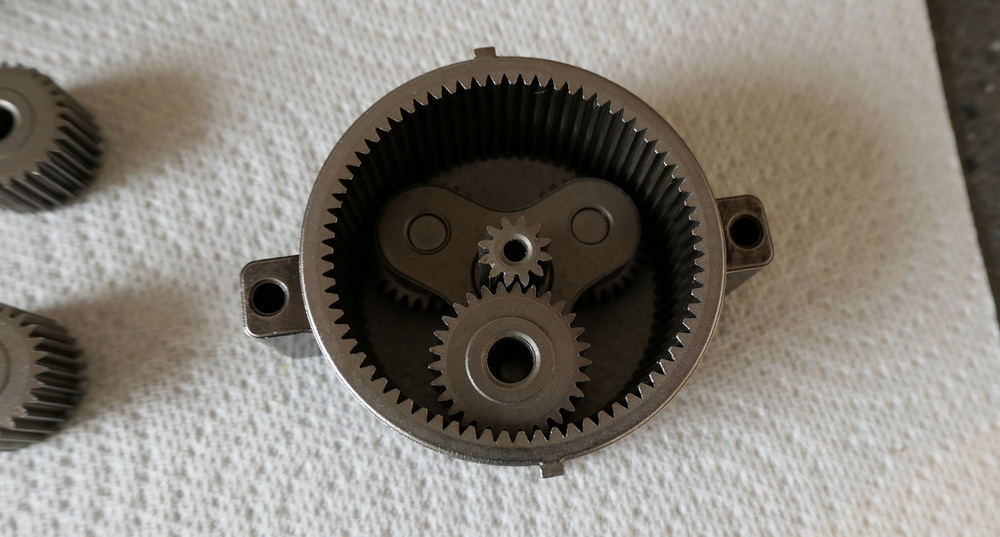

A planetary gearbox is built around three main elements: a central sun gear, several planet gears mounted on a carrier, and a surrounding internal ring gear. These components share a common axis, so the planetary gearbox transmits power through multiple gear meshes at the same time instead of relying on only one pair of gears.[2][1]

Because several planets engage simultaneously with the sun and ring gears, the planetary gearbox spreads load across many teeth, greatly reducing stress on each individual tooth. This multi-point contact is a key reason the planetary gearbox can remain compact yet still handle very high torque levels in heavy-duty applications.[3][1]

Engineers choose a planetary gearbox whenever they need to combine high torque, compact size, high efficiency, and long service life in one drive package. As a result, the planetary gearbox is widely used in servo systems, industrial machinery, tracked vehicles, hoists, and winch units where reliability and performance are essential.[4][2]

A planetary gearbox also offers excellent stiffness and low backlash, which helps maintain accurate and stable motion under dynamic loads. These properties make the planetary gearbox particularly attractive in modern machines that must be both powerful and precise.[5][1]

One of the strongest advantages of a planetary gearbox is its high torque density, meaning it can transmit more torque per unit weight and size than many other gearbox types. Because torque is shared between multiple planet gears, the planetary gearbox can operate with reduced tooth loading, allowing a smaller housing for the same or higher torque.[3][4]

This high torque density explains why a planetary gearbox is frequently used in travel drives, wheel drives, and winch drives on heavy equipment such as excavators, drilling rigs, and cranes. In these fields, a planetary gearbox provides the force needed to move, lift, and rotate large masses without requiring oversized motors or large external gear trains.[6][7]

Space is often limited inside modern machines, and the planetary gearbox addresses this challenge with a coaxial layout that keeps input and output shafts aligned. By arranging gears around a common center line, the planetary gearbox minimizes overall dimensions and reduces the need for additional support structures.[7][1]

This compact structure is especially valuable in tracked undercarriages, swing drives, and winch drives, where the planetary gearbox must fit inside an already crowded frame. A smaller and lighter planetary gearbox also helps reduce total machine weight, making transportation and installation easier while improving energy efficiency.[8][3]

The planetary gearbox is known for high mechanical efficiency, generally achieving around 90–96% per stage when properly designed and lubricated. Its mostly rolling tooth contact and optimized tooth geometry limit friction losses, meaning the planetary gearbox converts more input power into useful output torque.[9][1]

In addition, the balanced design of a planetary gearbox reduces vibration and noise, producing smooth power transmission that protects connected components. This smooth behavior is crucial for hoisting, winch, and travel systems, where a planetary gearbox must deliver controlled motion instead of jerky, shock-prone operation.[10][11]

When used in servo and automation systems, a planetary gearbox helps deliver precise motion by combining suitable gear ratios with low backlash and high torsional stiffness. The multi-gear engagement inside a planetary gearbox keeps backlash low, improving positioning accuracy in robotics, CNC machines, and packaging equipment.[1][5]

Low inertia designs allow a planetary gearbox to respond quickly to acceleration and deceleration commands from servo motors, supporting fast, repeatable movements. Because of this, a planetary gearbox is often the first choice when designers need speed control, torque multiplication, and tight precision in a single integrated drive.[5][10]

Thanks to its basic structure, a planetary gearbox can provide a wide range of reduction ratios simply by changing the tooth counts and deciding which element acts as the input, output, or stationary part. When two or more stages are combined, the planetary gearbox can achieve very high overall ratios while still keeping the package relatively short.[2][1]

This flexibility allows a planetary gearbox to be optimized for different tasks, such as slow, high-torque winch pulls, moderate-speed travel drives, or relatively high-speed slew drives. As machine requirements evolve, the planetary gearbox design can be adapted with new ratios or additional stages without completely redesigning the surrounding system.[8][2]

A planetary gearbox is also favored for its durability under demanding environmental and load conditions, including dust, moisture, shock, and continuous duty. Robust housings, high-strength alloy gears, and carefully engineered bearings help the planetary gearbox withstand high cyclic loads over many operating hours.[12][3]

Because the load is shared between multiple planets, a planetary gearbox tends to wear more evenly, resulting in longer service life and more predictable maintenance intervals. In industries where downtime is extremely costly, this durability makes the planetary gearbox a cost-effective long-term solution.[3][8]

In industrial power transmission, a planetary gearbox appears in mixers, conveyors, agitators, crushers, and rolling mills where compact high-torque drives are essential. Many heavy-duty industrial machines depend on a planetary gearbox to deliver slow, controlled rotation for process-critical shafts.[2][3]

Because of its efficiency and torque capacity, a planetary gearbox is also used in wind turbine pitch drives, solar trackers, and other renewable energy systems. In these applications, a planetary gearbox helps accurately adjust position while managing varying loads and environmental conditions.[10][2]

In mobile machinery such as excavators, drilling rigs, forestry harvesters, and mining loaders, the planetary gearbox is integrated into travel, swing, and winch systems. These machines require powerful, compact drives that can survive constant shock and varying load cycles, which suits the strengths of a planetary gearbox.[6][8]

Track drives often combine hydraulic motors with a planetary gearbox to produce high tractive effort at low speed while maintaining fine control. Similarly, swing drives and winch drives rely on a planetary gearbox to deliver rotational power that can start, stop, and hold heavy loads reliably and safely.[11][6]

Automatic transmissions are a classic example of how a planetary gearbox can provide multiple gear ratios in a compact layout. By changing which member is held, driven, or allowed to rotate freely, different gear ratios are achieved without needing many separate gear pairs, which is a major reason a planetary gearbox is used in vehicles.[1][2]

Electric and hybrid vehicles increasingly use a planetary gearbox in their e-drive units to match motor speed with wheel speed while optimizing torque and efficiency. The compactness and flexibility of a planetary gearbox help integrate electric motors, inverters, and mechanical drives into small, lightweight powertrain modules.[10][2]

In modern automation lines, robots and servo axes must move quickly, accurately, and repeatably, often under varying loads. A planetary gearbox is frequently mounted on servo motors to multiply torque while keeping backlash low enough for precise positioning.[5][1]

Because a planetary gearbox provides high torsional rigidity, it minimizes elastic twist between motor and load, which benefits dynamic performance. This makes a planetary gearbox particularly useful in pick-and-place systems, packaging machines, and advanced manufacturing cells where every millisecond and millimeter count.[5][10]

For Kemer, integrating a planetary gearbox into tracked chassis, hydraulic winches, travel drives, swing drives, and hydraulic motor packages is key to delivering compact yet powerful solutions. By using a planetary gearbox in each of these drive families, Kemer can offer consistent, high-torque performance across different machine platforms and industries.

Travel drives that combine a hydraulic motor with a planetary gearbox provide strong track torque for climbing slopes, turning under load, and working in mud or rough terrain. Winch drives use a planetary gearbox to achieve high pulling force with smooth, controllable drum rotation, while swing drives rely on a planetary gearbox to rotate upper structures with stability and precision.[6][8]

While a planetary gearbox is robust, proactive maintenance helps preserve its advantages over the long term. Regular inspection of lubricant condition, seals, bearings, and gear tooth surfaces ensures that the planetary gearbox continues to transmit torque efficiently and quietly.[12][3]

Good installation practices—correct alignment, proper fastening, and suitable motor or hydraulic connections—also contribute significantly to the long-term reliability of a planetary gearbox. When supported by proper maintenance schedules, a planetary gearbox can deliver long, trouble-free service, supporting high uptime and low total cost of ownership.[8][3]

Choosing a planetary gearbox can reduce overall system cost even when the initial unit price is higher than some traditional gearboxes. Because a planetary gearbox offers higher torque density and efficiency, it may allow a smaller motor, smaller structure, and reduced energy consumption across the life of the machine.[9][12]

The long service life and reliability of a planetary gearbox also lower maintenance and downtime costs, which can outweigh the purchase price difference. In many industrial and mobile applications, the planetary gearbox is therefore seen as a strategic investment that improves productivity and profitability.[2][3]

The planetary gearbox is used because it uniquely combines high torque density, compact design, high efficiency, and low backlash into a single, versatile transmission solution. From industrial machinery and automotive systems to tracked vehicles, winch drives, and swing drives, the planetary gearbox ensures powerful, efficient, and precise motion in environments where reliability cannot be compromised.[1][2]

For manufacturers like Kemer, the planetary gearbox is the foundation of advanced travel drives, winch drives, swing drives, and hydraulic motor solutions that serve demanding global customers. By leveraging the strengths of planetary gearbox technology, Kemer can deliver robust, space-saving drive systems that meet the evolving needs of construction, mining, energy, and industrial markets worldwide.

A planetary gearbox is a gear system with a central sun gear, multiple planet gears carried on a rotating carrier, and an outer ring gear, all sharing the same axis. This structure allows a planetary gearbox to transmit high torque through several gear meshes at once while keeping the design compact and efficient.[1][2]

A planetary gearbox is commonly used in automatic transmissions, servo and automation systems, travel drives, wheel drives, slew drives, and winch or hoisting systems. These applications rely on a planetary gearbox because they require high torque, space-saving design, and long-term reliability under heavy loads.[6][2]

A well-designed planetary gearbox typically reaches mechanical efficiency of about 90–96% per stage, depending on speed, load, and lubrication quality. This high efficiency helps a planetary gearbox minimize energy loss and heat generation, which improves overall system performance and reduces operating costs.[9][1]

Compared with many traditional parallel-shaft gearboxes, a planetary gearbox offers higher torque density, better load distribution, and a more compact layout. Under high torque and shock loads, a planetary gearbox often delivers better durability and efficiency, making it ideal for heavy-duty and space-limited applications.[13][3]

In servo and robotic systems, a planetary gearbox provides suitable reduction ratios with low backlash and high torsional stiffness, improving positioning accuracy. By reducing inertia and elastic twist between motor and load, a planetary gearbox enhances responsiveness and repeatability in fast, precise motion tasks.[10][5]

[1](https://teknic.com/what-is-a-planetary-gearbox/)

[2](https://www.inctmotion.com/news/what-are-planetary-gears-used-for)

[3](https://www.millgears.com/heavy-duty-planetary-gearbox-solutions)

[4](https://assunmotor.com/blog/planetary-gearbox/)

[5](https://www.linearmotiontips.com/why-are-planetary-gearboxes-preferred-for-servo-applications/)

[6](https://kavitsu.com/in-what-applications-are-planetary-gearboxes-commonly-used-and-why.php)

[7](https://www.santramengineers.com/the-role-of-planetary-gearboxes-in-high-torque-applications/)

[8](https://www.guomaolide.com/2025/10/31/how-planetary-gearboxes-improve-efficiency-in-industrial-applications/)

[9](https://www.inctmotion.com/news/planetary-gearbox-efficiency-a-comprehensive-analysis)

[10](https://kavitsu.com/exploring-the-efficiency-of-planetary-gearboxes.php)

[11](https://www.bloommfg.com/blog/post/understanding-planetary-winches-key-features-and-benefits-for-your-heavy-duty-operations)

[12](https://tanhon.com/advantages-and-disadvantages-of-planetary-gearboxes/)

[13](https://www.faulhaber.com/en/products/precision-gearheads/planetary-gearheads/)