Views: 222 Author: Robert Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is a Rubber Track System?

● Why Source from Chinese Rubber Track System Manufacturers?

● Application Fields for Rubber Track Systems

● Key Components of a Rubber Track System

● Top 10 Rubber Track System Manufacturers in China

>> Ningbo Kemer Engineering Machinery Co., Ltd.

>> Xiamen Worthpart Machinery Co., Ltd.

>> Shandong Cnmc Machinery Co., Ltd.

>> Quanzhou Fulian Machinery Equipment Co., Ltd.

>> Quanzhou Nanfeng Machinery Manufacturing Co., Ltd.

>> Shandong Mingko Industry Corporation

>> Shanghai Puyi Industrial Co., Ltd.

>> Jiaxing Taite Rubber Co., Ltd.

>> Modular Tracked Undercarriage Suppliers

>> Agricultural Rubber Track Conversion System Suppliers

● How to Evaluate Rubber Track System Manufacturers

● Cooperation Models with Rubber Track System Manufacturers

>> 3. Fully integrated systems

● FAQs about Rubber Track System Manufacturers

>> 1 What machines typically use rubber track systems?

>> 2 How do Rubber Track System Manufacturers help OEMs during development?

>> 3 What should buyers check when auditing a Rubber Track System Manufacturer?

>> 4 Can Rubber Track System Manufacturers provide both rubber and steel undercarriages?

>> 5 How can OEMs reduce lifecycle costs with the right Rubber Track System Manufacturer?

China has become a global hub for high‑performance rubber track systems, supplying complete crawler undercarriages for excavators, drilling rigs, crawler carriers, agricultural machines, and special vehicles. These Rubber Track System Manufacturers combine rubber tracks, undercarriage frames, rollers, idlers, and integrated travel drives to deliver turnkey mobility solutions for OEMs worldwide. For international buyers, understanding the strengths of leading Chinese Rubber Track System Manufacturers is essential to secure reliable, customizable, and cost‑effective crawler solutions.

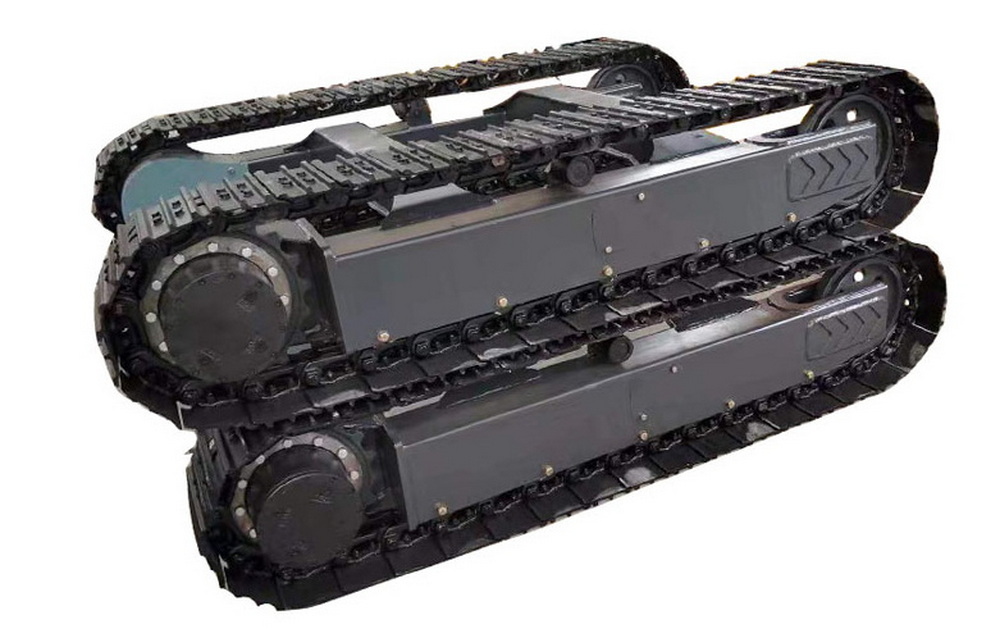

A rubber track system is a complete undercarriage module that supports and propels a machine using continuous rubber tracks instead of tires or steel tracks. It typically includes components such as rubber tracks, track frames, rollers, idlers, sprockets, and travel drives matched to the machine's torque and speed requirements. Compared with conventional wheel axles or steel tracks, a well‑designed rubber track system offers lower ground pressure, reduced vibration, and improved traction on soft or delicate surfaces such as soil, turf, and asphalt.

Typical rubber track system configurations include compact crawler undercarriages for mini excavators and drilling rigs, rubber track conversion systems for agricultural tractors, and custom crawler chassis for aerial work platforms, pavers, and industrial carriers. For OEMs, sourcing from Rubber Track System Manufacturers that provide complete systems rather than loose parts simplifies engineering, reduces integration risk, and shortens development time. Modern manufacturers can supply “bolt‑on” rubber track systems that mount directly under the machine frame with defined interfaces, making it easier to move from prototype to series production.

Chinese Rubber Track System Manufacturers benefit from dense industrial clusters, mature export infrastructure, and a wide network of component suppliers. This ecosystem enables competitive pricing and fast turnaround from design to production. Many factories operate in provinces such as Zhejiang, Fujian, Shandong, and Shanghai, where rubber processing, steel fabrication, machining, and hydraulic components are all available locally. As a result, OEMs can obtain complete rubber track systems that are both cost‑effective and technically robust.

Another key advantage is engineering flexibility. Chinese Rubber Track System Manufacturers increasingly focus on customization, offering different track widths, gauges, frame lengths, and mounting patterns to match OEM machine layouts. Suppliers can adapt travel drives, gear ratios, and hydraulic motor sizes to meet required travel speeds, gradeability, and load conditions. For global buyers, the combination of technical capability, customization, and export experience makes these manufacturers attractive partners for long‑term crawler system development.

Rubber track systems are used across multiple industries where machines must operate on soft, uneven, or sensitive ground:

- Construction and civil engineering

- Mining and tunneling

- Agriculture and forestry

- Pipeline and drilling projects

- Municipal and urban maintenance

- Special industrial transport and logistics

In construction, mini excavators, compact track loaders, and crawler carriers rely on rubber track systems to move safely and efficiently on job sites with mixed ground conditions. In agriculture, rubber track conversion systems allow tractors and harvesters to reduce soil compaction and maintain traction in wet fields. In specialized applications such as drilling rigs, aerial platforms, and pavers, modular rubber track undercarriages give equipment designers more freedom to optimize stability and maneuverability.

For each of these segments, dedicated Rubber Track System Manufacturers offer tailored solutions, adjusting track design, frame structure, and drive components according to working conditions. This segmentation allows OEMs to select partners with deep experience in their specific application rather than using generic undercarriages.

To understand what makes one Rubber Track System Manufacturer more valuable than another, it is helpful to look at each core component of the system:

- Rubber tracks: Use specialized rubber compounds and embedded steel cords to balance wear resistance, flexibility, and tensile strength. Tread patterns are optimized for traction, self‑cleaning, and surface protection.

- Track frames: Welded steel structures that carry loads from the machine into the tracks. Their geometry affects stability, ground clearance, and the ease of mounting to the main chassis.

- Rollers and idlers: Support and guide the rubber tracks, controlling contact pressure and reducing vibration. Quality rollers and idlers extend track life and improve operator comfort.

- Sprockets: Transfer torque from the travel drive to the tracks. Proper tooth design and matching with the track pitch are essential for smooth, low‑noise operation.

- Travel drives: Usually compact planetary gearboxes combined with hydraulic motors. These define travel speed, tractive effort, and braking characteristics of the rubber track system.

Leading Rubber Track System Manufacturers not only produce these parts but also integrate them into complete, tested undercarriage modules. This integration ensures compatibility between mechanical and hydraulic components, minimizing failures and simplifying installation for OEMs.

The following companies are widely recognized in export markets for their capabilities in rubber tracks, crawler chassis, and complete rubber track undercarriages. Each Rubber Track System Manufacturer offers different strengths in terms of engineering, customization, and application focus.

Ningbo Kemer is a specialized manufacturer of crawler undercarriage systems that integrates rubber track chassis with hydraulic winches, planetary gearboxes, travel drives, swing drives, and hydraulic motors. As a system‑oriented Rubber Track System Manufacturer, Kemer goes beyond supplying basic tracks and frames, offering complete drive solutions matched to the undercarriage. This makes Kemer a strong partner for OEMs seeking high‑performance crawler systems for drilling rigs, aerial platforms, crawler carriers, and other special equipment.

Kemer's engineering team can design custom crawler frames and rubber track systems according to machine weight, center of gravity, and working conditions. Parameters such as track gauge, frame length, roller arrangement, and drive torque can be adjusted to deliver the required stability and traction. By supplying integrated travel drives and gearboxes, Kemer helps OEMs avoid compatibility problems between mechanical structures and hydraulic components. This holistic approach is one reason many global buyers regard Ningbo Kemer as a preferred Rubber Track System Manufacturer for demanding projects.

Xiamen Worthpart is well known internationally for rubber tracks and undercarriage components for excavators and compact equipment. Acting as a Rubber Track System Manufacturer, Worthpart offers a wide product range suitable for mini excavators, skid steers, and compact track loaders. The company focuses on durable rubber compounds, precise bonding processes, and accurate track dimensions to ensure long service life and smooth running.

For OEMs and distributors, Xiamen Worthpart offers flexible order quantities and fast communication, which are important when managing fleet maintenance or introducing new machine models. Their experience with multiple global brands helps ensure compatibility with existing undercarriage platforms, making them a reliable Rubber Track System Manufacturer for both OEM fitment and aftermarket support.

Shandong Cnmc operates in a large industrial complex and supplies rubber tracks and related components for a broad range of construction machinery. As one of the established Rubber Track System Manufacturers in northern China, Cnmc serves both OEMs and the replacement market with moderate to large volume capability. Its production scale allows for stable supply and competitive pricing on full container shipments.

In addition to rubber tracks, Cnmc can combine rollers, idlers, sprockets, and other undercarriage parts in consolidated orders. This reduces procurement complexity for buyers who need complete rubber track systems or stocking packages for multiple machine models. As a Rubber Track System Manufacturer, Shandong Cnmc's strength lies in volume capacity and the ability to support distributors and equipment producers simultaneously.

Quanzhou Fulian is based in the Fujian industrial cluster, a region known for undercarriage components and rubber track production. Fulian focuses on rubber tracks and matched undercarriage parts for excavators and construction equipment, positioning itself as a flexible Rubber Track System Manufacturer for small to medium batch orders. Its location near other component suppliers and ports simplifies logistics and shortens lead times.

For OEMs developing new models or managing diverse fleets, Fulian can supply different sizes of rubber tracks along with compatible rollers, idlers, and sprockets. This combination supports consistent performance across multiple machine platforms. As a Rubber Track System Manufacturer, Fulian is well suited to customers who value responsive service and the ability to purchase complete undercarriage packages from one source.

Quanzhou Nanfeng specializes in rubber tracks and undercarriage components primarily for mini excavators and compact equipment. This specialization enables Nanfeng to refine its product designs for smaller machines, where low noise, smooth travel, and ground protection are particularly important. As a Rubber Track System Manufacturer, Nanfeng provides cost‑effective options for OEMs, rental fleets, and aftermarket distributors.

Buyers often choose Nanfeng for smaller equipment ranges, where agility and quick adaptation to new model requirements matter more than very high volume. Its flexible production and proximity to logistics hubs help reduce lead times, making Nanfeng a practical Rubber Track System Manufacturer for markets that require short delivery cycles and reliable quality.

Shandong Mingko combines rubber track production with heavy‑duty machinery parts in a large manufacturing facility, giving it strong capacity for both small and large undercarriage components. As a Rubber Track System Manufacturer, Mingko targets OEMs and distributors looking for consistent quality and bulk supply. Its extensive production area supports automated processes and thorough quality control.

Mingko is particularly suitable for customers needing mixed shipments of rubber tracks, steel undercarriage parts, and related components. This ability to bundle multiple product categories in one container simplifies sourcing and stock management. For companies building or maintaining a wide range of machines, Shandong Mingko stands out among Rubber Track System Manufacturers as a scalable and versatile supplier.

Shanghai Puyi operates close to major ports and provides rubber tracks and undercarriage solutions for excavators, agricultural machinery, and special vehicles. With experience in rubber compounding and track production, Puyi is recognized as a Rubber Track System Manufacturer that emphasizes export readiness and stable quality. Its proximity to Shanghai's logistics infrastructure supports reliable shipping schedules and competitive delivery times.

Puyi's product line covers standard excavator rubber tracks, continuous tracks for crawler carriers, and specialized tracks for agriculture. For OEMs, this breadth means a single partner can support different machine families with consistent technical standards. As a Rubber Track System Manufacturer, Shanghai Puyi is well suited to equipment builders working across multiple sectors.

Jiaxing Taite Rubber focuses on skid steer rubber tracks and rubber excavator tracks, with a strong emphasis on durability for compact equipment. This specialization has established Taite as a dedicated Rubber Track System Manufacturer for skid steers, compact track loaders, and mini excavators operating in rental fleets and demanding urban sites. High wear resistance and consistent dimensions are top priorities.

Equipment owners and OEMs often select Taite when they need reliable performance in tight spaces, where machine downtime is costly and track replacement should be as infrequent as possible. By focusing its engineering resources on compact machinery, Taite strengthens its position as a precision‑oriented Rubber Track System Manufacturer with a clear application niche.

In addition to traditional rubber track factories, China hosts several specialized companies that design and build modular tracked undercarriage systems. These suppliers act as Rubber Track System Manufacturers that deliver complete crawler modules with frames, rollers, idlers, sprockets, and integrated travel drives. They often serve OEMs developing drilling rigs, aerial work platforms, crawler cranes, and industrial carriers requiring custom chassis.

Such manufacturers work closely with customers to adjust frame geometry, support loads, and ensure machine stability on various gradients. Their ability to integrate hydraulic motors and planetary gearboxes into the rubber track system simplifies installation for OEMs, who can bolt the entire module to the machine structure. For customers seeking a truly plug‑and‑play solution, modular undercarriage suppliers are highly attractive Rubber Track System Manufacturers.

Another important segment of Rubber Track System Manufacturers in China focuses on agricultural rubber track conversion systems for tractors, harvesters, and other farm equipment. These systems replace wheel axles with rubber track modules, improving traction, flotation, and ride comfort in fields. They are particularly valuable in regions with heavy soils or frequent rainfall, where wheeled tractors may struggle.

Agricultural rubber track system suppliers design frames and track units that align with tractor mounting interfaces and power outputs, ensuring that the conversion does not overload driveline components. As specialized Rubber Track System Manufacturers, they often offer different ranges based on horsepower, track width, and field conditions. This helps farmers and agricultural OEMs choose configurations that match local cropping systems and terrain.

When selecting among Rubber Track System Manufacturers, OEMs should conduct a systematic evaluation that goes beyond initial unit price. Important factors include:

- Engineering competence: Ability to calculate required track contact length, roller arrangement, and drive torque based on machine weight and duty cycle. A capable Rubber Track System Manufacturer can propose optimized designs rather than just following a rough drawing.

- Quality assurance: Existence of formal quality systems, material testing, and durability checks. Manufacturers with clear inspection routines and track life data provide more predictable performance in the field.

- Customization capability: Flexibility to adapt track sizes, frame designs, and drive selections without excessive minimum order quantities. This is crucial for specialized machines or low‑volume OEMs.

- Communication and documentation: Clear technical drawings, 3D models, installation manuals, and responsive support during design, prototype testing, and series production.

- After‑sales support: Availability of spare tracks and parts, stable references, and transparent warranty policies from the Rubber Track System Manufacturer.

By weighting these criteria, buyers can identify Rubber Track System Manufacturers that align with their technical requirements, business strategy, and long‑term maintenance plans.

Working with Rubber Track System Manufacturers can follow different cooperation models, depending on the stage and scale of an OEM project:

OEMs purchase loose rubber tracks, rollers, and sprockets to combine with their own frames and drives. This requires strong internal engineering but gives full control over undercarriage design.

The manufacturer supplies rubber tracks and frames, while the OEM selects travel drives and hydraulics. Here, the Rubber Track System Manufacturer must coordinate interface dimensions and load data with the OEM.

The Rubber Track System Manufacturer delivers complete undercarriage modules with frames, tracks, rollers, idlers, sprockets, and travel drives, sometimes including brakes and hoses. This model reduces integration risk and speeds up time to market.

For many international OEMs, partnering with a system‑oriented Rubber Track System Manufacturer like Kemer and other integrated suppliers offers the best balance of speed, reliability, and lifecycle cost control.

Chinese Rubber Track System Manufacturers have moved far beyond basic component production and now act as full engineering partners for global OEMs. By combining rubber tracks, frames, rollers, idlers, sprockets, and integrated travel drives, these manufacturers provide complete crawler undercarriages ready to mount under modern construction, agricultural, and industrial machines. Companies such as Ningbo Kemer, Xiamen Worthpart, Shandong Cnmc, Quanzhou Fulian, and others represent the diversity and strength of China's undercarriage industry.

For equipment builders, the right Rubber Track System Manufacturer can significantly shorten development cycles, improve machine performance, and reduce total cost of ownership. Evaluating suppliers on engineering capability, quality management, customization, and support helps ensure successful long‑term cooperation. As demand for efficient, low‑impact mobility grows across industries, Chinese Rubber Track System Manufacturers will continue to play a central role in delivering high‑value crawler solutions to the global market.

Rubber track systems are common on mini excavators, compact track loaders, drilling rigs, crawler carriers, small pavers, agricultural tractors with conversion kits, and various special industrial vehicles. These machines benefit from low ground pressure, high traction, and reduced vibration provided by rubber tracks. Rubber Track System Manufacturers design undercarriages with different sizes and load capacities so OEMs can match the system to the machine's working environment and stability needs.

Rubber Track System Manufacturers support OEMs by analyzing machine weight, center of gravity, desired speed, and gradient capability, then proposing suitable track widths, gauges, and travel drive configurations. They can provide drawings, 3D models, and prototype undercarriages for testing, then refine designs based on field feedback. This collaborative engineering approach enables OEMs to optimize stability, durability, and ride comfort before entering mass production.

When auditing a Rubber Track System Manufacturer, buyers should review production facilities, material storage, mixing and curing processes, welding quality, machining precision, and inspection procedures. It is also useful to check sample track sections, cutaways, and test reports that show bonding quality and wear performance. Meeting with engineers and quality managers helps verify the manufacturer's ability to handle customized projects and long‑term technical support.

Many Rubber Track System Manufacturers focus mainly on rubber solutions, but some also produce steel track undercarriages for heavier machines. These suppliers can offer a complete portfolio, allowing OEMs to select rubber or steel versions depending on application, load, and ground conditions. Choosing a manufacturer with both technologies can be advantageous when a product family includes compact rubber‑tracked models and larger steel‑tracked variants.

OEMs can reduce lifecycle costs by working with Rubber Track System Manufacturers that prioritize wear resistance, proper load distribution, and robust travel drive design. High‑quality rubber compounds, well‑designed frames, and matched gear ratios reduce premature failures and downtime. Additionally, suppliers that ensure consistent part availability and stable pricing help OEMs and fleet operators manage maintenance budgets more effectively over the life of the equipment.