Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

● Safety, Tools, and Pre‑Installation Checks

● Planning Mounting Location and Orientation

● Mechanical Mounting of the Hydraulic Winch

● Mounting the Hydraulic Solenoid Valve Block

● Plumbing the Hydraulic System to the Vehicle

● Filling and Bleeding the Hydraulic System

● Spooling and Tensioning the Winch Cable

● Testing and Final Safety Checks

● FAQ

>> 1. What tools are needed to install a Mile Marker hydraulic winch?

>> 2. Can I connect the hydraulic winch to any power steering system?

>> 3. How do I know the hydraulic winch is mounted correctly?

>> 4. How often should the hydraulic winch be serviced after installation?

>> 5. What common mistakes should be avoided during installation?

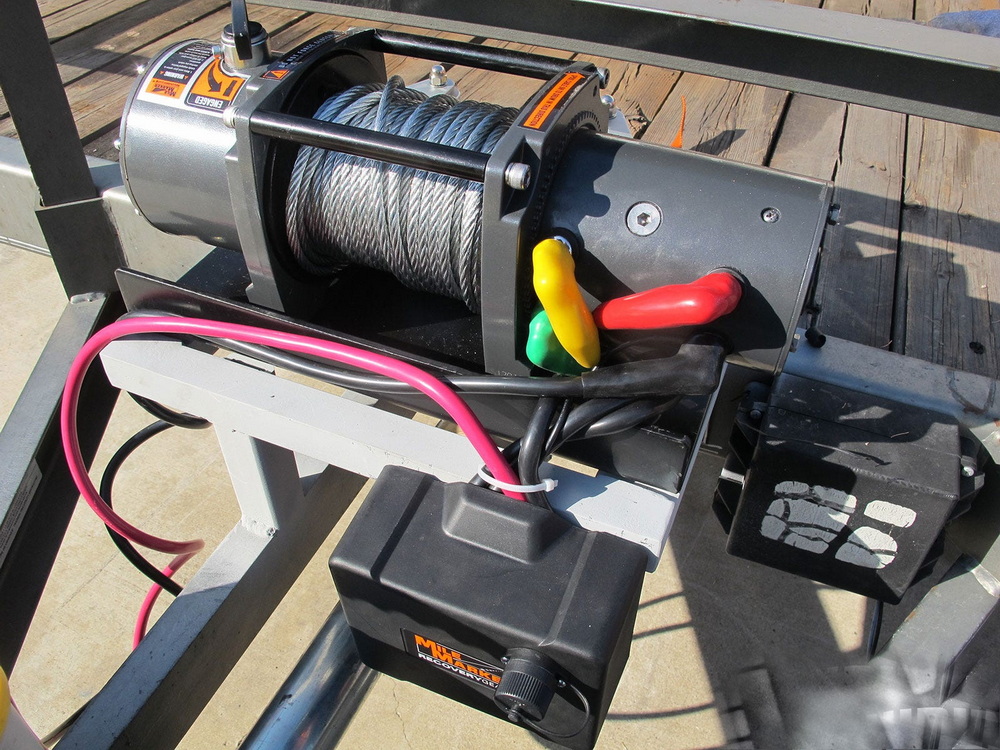

Installing a Mile Marker hydraulic winch is a precision job that combines mechanical mounting, hydraulic plumbing, and electrical control wiring in one system. A correct hydraulic winch installation ensures safe pulling performance, protects the vehicle steering system, and maximizes the service life of your hydraulic winch.[1][2]

A Mile Marker hydraulic winch is a powerful pulling device, so all installation work must follow the official installation and operator's manual for the specific model (HI9000, H10500, H12000, 70/75 Series, etc.). Before starting, read all safety warnings about line routing, load rating, and working around power steering and hydraulic systems in the Mile Marker hydraulic winch documentation.[2][3][1]

To prepare for installing a Mile Marker hydraulic winch, gather basic hand tools, torque wrench, drill and bits (if the bumper or tray is not pre‑drilled), thread locker, hydraulic hose wrenches, and personal protective equipment such as gloves and eye protection. The vehicle must be parked on level ground, engine off, wheels chocked, and the battery disconnected before starting work on the hydraulic winch installation.[3][2]

Before mounting the hydraulic winch, verify that the vehicle frame, bumper, or winch tray is free from corrosion, cracks, or prior accident damage that could weaken the structure under load. Any damaged mounting area should be professionally repaired or replaced so that the hydraulic winch can safely transmit full rated line pull into the chassis.[2][3]

- Verify the vehicle's power steering pump capacity and compatibility with the chosen Mile Marker hydraulic winch kit.[4][2]

- Confirm that the winch mount or bumper is rated for the full line pull of the hydraulic winch and that the bolt pattern matches the Mile Marker mounting specification.[2]

- Inspect the hydraulic winch, drum, and steel cable or synthetic rope for shipping damage before installation.[3]

A Mile Marker hydraulic winch is intended for permanent mounting on a structural front or rear vehicle location, usually a dedicated winch tray or heavy‑duty bumper. The installation manual specifies that the hydraulic winch must be bolted to a structure that can withstand the full rated line pull without deformation or cracking.[4][3][2]

For most Mile Marker 2‑speed hydraulic winches, the control levers (Free/Low, High) should sit on the left (passenger) side when facing the grill, with the Free/Low lever on the top, and the four primary mounting holes on the bottom. The cable must always spool off the bottom of the drum, which affects how you position the hydraulic winch relative to the fairlead and frame.[2]

When planning the location, make sure that the hydraulic winch does not block critical airflow to the radiator, intercooler, or transmission cooler, especially on vehicles used for towing or off‑road climbing. If necessary, use a recessed tray or low‑profile bumper design to keep the hydraulic winch compact while preserving front‑end cooling performance.[5]

- Ensure enough clearance around the hydraulic winch motor, valve block, and drum ends for service and hose routing.[2]

- Check that the fairlead opening lines up with the center of the hydraulic winch drum to avoid side loading during winch operation.[2]

- Plan the position of the control plug, hand control, and any guard plate to protect hydraulic winch components from road debris.[3]

The core of the installation is mechanically securing the Mile Marker hydraulic winch to the winch tray or bumper using the recommended capscrews and torque values. Many Mile Marker mounting systems come pre‑drilled with the correct hole pattern for the hydraulic winch and an integrated fairlead mounting location.[2]

1. If needed, drill four mounting holes according to the hydraulic winch bolt pattern using the diameter specified in the manual (commonly around 10 mm or 3/8 in).[2]

2. Position the Mile Marker hydraulic winch so the drum aligns with the fairlead and the levers are on the correct side, then install the capscrews through the mounting tray into the winch body legs.[2]

3. Tighten the bolts evenly to the torque specified (for example around 35 ft‑lb for some 3/8 in capscrews) and verify there are enough threads engaged in each winch leg, typically 6–10 threads.[2]

The fairlead must be firmly attached in front of the hydraulic winch drum using the pre‑drilled holes on the tray or bumper. All fasteners for the hydraulic winch and fairlead should be of grade and length equal or superior to those supplied by Mile Marker in the kit.[3][2]

Where the tray or bumper is not supplied by Mile Marker, the installer should use thick plate, properly gusseted to the frame, so that the hydraulic winch does not twist the mount during angled pulls. Welded joints on custom mounts must be carried out by qualified welders because a failed mount under load can cause the hydraulic winch to detach suddenly from the vehicle.[6]

A Mile Marker hydraulic winch usually uses an integrated solenoid control valve mounted directly to the motor or near the winch. This valve block controls hydraulic oil flow to the hydraulic winch motor and connects to the steering pump circuit through high‑pressure hoses.[7][4][2]

- Remove the rubber plugs in the motor ports and transfer the square‑cut O‑rings from the plugs into the motor port grooves as specified in the instructions.[2]

- Assemble the valve block with the correct thin O‑rings, metal washers, and flow disk in the port labeled “1,” ensuring the flat side faces the valve and the cut side faces the hydraulic winch motor.[2]

- Fasten the valve block to the hydraulic winch motor using the supplied socket head cap screws, apply thread locker, and torque to the specified value (for example around 25 ft‑lb in some manuals).[2]

The “P” and “T” ports on the Mile Marker hydraulic solenoid valve block will receive the fittings for the pressure and return hoses from the engine bay. Choose a valve port orientation that allows gentle hose bends, avoids exhaust heat, and prevents contact with sharp edges or moving suspension parts.[6][2]

On some vehicles, there may be more convenient remote mounting locations for the valve block to simplify hose routing while still keeping the hydraulic winch plumbing short and efficient. In such cases, a rigid bracket or crossmember plate is often used so that the valve stays secure and does not vibrate or fatigue the hydraulic hoses during off‑road use.[6]

The defining feature of a Mile Marker hydraulic winch is that it runs from the vehicle's power steering pump rather than from an electric motor. A typical Mile Marker hydraulic winch installation inserts the winch valve in series with the high‑pressure line between the power steering pump and steering box or rack, with a return line back to the reservoir.[5][4][6][2]

1. Place a drain pan under the vehicle and carefully remove the factory high‑pressure hose from the power steering pump to the steering box or hydroboost.[2]

2. Install the Mile Marker steering pump adapter on the pump outlet and the steering box adapter on the steering gear input, tightening both to factory specifications.[2]

3. Connect the long high‑pressure hose from the valve “P” (pressure out) port to the steering pump adapter, and the other hose from the valve “T” (return) port to the steering box or rack according to the hydraulic winch manual diagrams.[6][2]

All Mile Marker hydraulic winch hose connections must be fully tightened, leak‑free, and routed away from hot or moving parts. The instructions emphasize that hydraulic lines cannot rub on abrasive or vibrating surfaces and must be clipped or tied securely along the chassis or crossmember.[3][2]

If the vehicle uses a hydroboost brake system, the hydraulic winch plumbing must be arranged exactly as shown in the dedicated schematics so that braking performance is not compromised. In some applications, Mile Marker offers specific kits or parts numbers for different truck platforms so the hydraulic winch can be integrated without custom hoses or adapters.[8][4]

Though the Mile Marker hydraulic winch is hydraulically powered, it still uses a low‑voltage electrical control circuit for the solenoid valve and hand control. The manual supplies a wiring diagram that must be followed exactly to prevent reversed winch direction or unsafe operation of the hydraulic winch.[3][2]

- Mount the circuit breaker under the hood in a convenient, dry location and connect it to the battery positive terminal using the specified gauge cable.[2]

- Connect the solenoid coil wires to the control plug box: typically two black wires for each solenoid, with pairs pre‑connected and grounded, plus separate wires that mate with the white and black leads from the hand control connector.[2]

- If the hand control direction is reversed (IN/OUT swapped), simply reverse the two control wires as instructed in the Mile Marker hydraulic winch manual.[3]

All wiring for the hydraulic winch control should be protected in conduit or loom and routed away from sharp edges, high heat zones, and moving steering components. The hand controller should be stored in a safe location when not in use to prevent accidental operation of the hydraulic winch by unauthorized persons.[3]

Some Mile Marker hydraulic winch setups can be connected to in‑cab rocker switches or integrated into factory auxiliary switch panels for easier operation. In that case, relays and proper fusing are required so that the hydraulic winch controls remain safe and do not overload original vehicle wiring circuits.[5][3]

Once the mechanical, hydraulic, and electrical parts of the Mile Marker hydraulic winch are installed, the power steering system must be refilled and bled of air. This step is critical because trapped air can reduce steering assist, cause noise, and affect performance of the hydraulic winch.[4][3]

1. Fill the power steering reservoir with the manufacturer‑recommended fluid until full.[3]

2. Start the engine and momentarily power the hydraulic winch cable out a few feet using the control switch.[3]

3. Shut off the engine, check the reservoir, and top up fluid if necessary, then repeat the process of running the hydraulic winch and turning the vehicle's steering wheel lock‑to‑lock several times to purge air.[3]

During bleeding, always monitor for leaks at the Mile Marker hydraulic winch valve, pump adapter, steering box adapter, and all hose connections. If any foaming, whining, or steering irregularities appear, stop and confirm that all hoses and fittings are tight and correctly installed before further operation of the hydraulic winch.[6][3][2]

On first road tests after installing the hydraulic winch, pay attention to steering feel at low speed and during parking maneuvers, because poor bleeding can show up as heavy or jerky steering. If symptoms persist, the system should be re‑bled or inspected by a hydraulic or steering specialist before the hydraulic winch is used under heavy load.[3]

Correctly spooling the rope on the hydraulic winch drum is essential for safety and to prevent damage to the line. Mile Marker manuals specify that steel cable must be wound onto the drum under a minimum load (commonly around 500 lb) so that the outer wraps do not pull down into the lower layers.[3]

- Run the hydraulic winch in “FREE” mode to pull out most of the cable, leaving only a few wraps on the drum.[7][2]

- Attach the hook to a suitable anchor and slowly winch in under load, guiding the cable with light tension and keeping hands and clothing away from the fairlead opening.[3]

- Build up even, tight layers of rope across the full drum width, always ensuring the hydraulic winch cable spools off the bottom of the drum during future use.[3][2]

Never put fingers through the hook, never cross over or under a taut cable, and never stand in the direct line of the rope when the hydraulic winch is pulling. The hydraulic winch area must remain clear of bystanders at all times during tensioning or operational pulls.[5][3]

If using synthetic rope on a Mile Marker hydraulic winch, follow the rope supplier's recommendations for initial pre‑stretching and protection from abrasion and heat. Synthetic lines are often lighter and safer if they break, but they still require proper spooling and regular inspection to keep the hydraulic winch system reliable.[5]

After installation and spooling, perform a controlled test of the Mile Marker hydraulic winch in both directions and at different speeds. The test verifies that the hydraulic winch responds correctly to the hand control, that the valve block functions, and that the steering system still works normally.[7][5][3]

- With the vehicle secured and wheels chocked, operate the hydraulic winch in and out for short intervals, checking for smooth drum rotation and listening for abnormal noises.[3]

- Confirm that the gear‑shift levers (LOW, HIGH, FREE) engage correctly and that the hydraulic winch does not creep under load when the control is released.[7][2]

- Inspect all hoses, fittings, and electrical cables once more for leaks, overheating, or chafing caused by the first test runs of the hydraulic winch.[3][2]

Mile Marker clearly states that hydraulic winches are not designed for lifting or supporting people or loads vertically, and overloading must be strictly avoided. Maximum line pull ratings apply only on the first drum layer, and operators must always monitor line angle, vehicle stability, and anchor integrity when using the hydraulic winch.[7][5][3]

For long‑term reliability, keep a record of the installation date, model and serial number of the hydraulic winch, and any custom hoses or fittings used. This documentation simplifies future troubleshooting, parts ordering, and service planning for the hydraulic winch system on the vehicle.[3]

Installing a Mile Marker hydraulic winch is a structured process that combines mechanical, hydraulic, and electrical disciplines, so careful planning and adherence to the official manual are essential. A correctly mounted and plumbed hydraulic winch integrated into the vehicle power steering circuit delivers reliable, high‑duty pulling performance while maintaining safe steering behavior and long component life. When every step—from tray mounting and valve orientation to hose routing, bleeding, and controlled testing—is executed precisely, the Mile Marker hydraulic winch becomes a robust recovery and utility tool for both on‑road and off‑road applications.[1][5][7][2][3]

A basic Mile Marker hydraulic winch installation usually requires metric/imperial socket sets, open‑end wrenches, a torque wrench, drill and bits for mounting holes, hose wrenches, and thread locker. Safety gear such as gloves, eye protection, and proper lifting equipment for the hydraulic winch are also recommended because the unit is heavy and the installation involves pressurized fluid lines.[2][3]

Most Mile Marker hydraulic winch kits are designed to tap into standard power steering circuits using model‑specific adapters and hoses, but the steering pump must meet the flow and pressure requirements listed in the manual. If the pump output is marginal or the vehicle uses an unusual steering or hydroboost configuration, professional evaluation is advised before installing the hydraulic winch.[4][6][2]

A properly mounted Mile Marker hydraulic winch will sit square to the fairlead, with the drum centered in the opening, levers in the specified orientation, and all bolts tightened to the torque values given in the instructions. There should be no flexing of the tray or bumper when the hydraulic winch is loaded, and the cable must spool cleanly off the bottom of the drum during operation.[7][2]

Mile Marker recommends regular inspection of the hydraulic winch cable, drum, mounting bolts, hydraulic hoses, and connections, especially after heavy use or long storage. Routine tasks include checking for leaks, re‑torquing major fasteners, verifying fluid level and quality, and re‑spooling the line under tension to maintain neat wraps on the hydraulic winch drum.[5][3]

Common errors include routing hoses where they can rub or overheat, using undersized or low‑grade mounting bolts, failing to bleed air fully from the steering circuit, or allowing the hydraulic winch cable to spool off the top of the drum. Skipping the initial tensioning pull or ignoring Mile Marker's warnings about overloading and safe working procedures can also damage the hydraulic winch and create serious safety hazards.[7][2][3]

[1](https://www.milemarker.com/pages/installation-instructions)

[2](https://studylib.net/doc/25621924/mile-marker-75-series-hi9000-9000-lb-hydraulic-winch-inst...)

[3](https://manuals.plus/mile-marker/h10500-hydraulic-winch-manual)

[4](https://www.truckspring.com/installation-instructions/milemarker/75-52000C-24-hi_specs.pdf%3Fsrsltid=AfmBOoqvdru5kgSenisuSTlskFtkLmPjrUuskeohhDZiA67yT8ggG70j)

[5](https://www.milemarker.com)

[6](https://www.landcruiserclub.net/community/threads/how-to-fit-mile-marker-hydraulic-winch.127487/)

[7](https://static.summitracing.com/global/images/instructions/mmk-75-52000c.pdf)

[8](https://www.otrtrading.co.za/installation_manuals.htm)

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey