Views: 222 Author: Robert Publish Time: 2026-01-13 Origin: Site

Content Menu

● Core Advantages of Hydraulic Winch Systems

● Marine and Offshore Applications

● Construction and Civil Engineering Applications

● Mining, Quarrying, and Tunneling Applications

● Forestry, Logging, and Agricultural Applications

● Vehicle Recovery, Off‑Road, and Military Applications

● Oil, Gas, and Energy Sector Applications

● Industrial, Manufacturing, and Dockside Applications

● Integration with Tracked Undercarriages and Hydraulic Drives

● Selecting the Right Hydraulic Winch

● Operation and Safety Considerations

● Maintenance of Hydraulic Winches

● FAQ About Hydraulic Winch Applications

>> 1. Where is a hydraulic winch most commonly installed?

>> 2. Why choose a hydraulic winch instead of an electric winch?

>> 3. Can a hydraulic winch be used underwater or offshore?

>> 4. What maintenance does a hydraulic winch require on heavy equipment?

>> 5. How does a hydraulic winch improve safety on job sites?

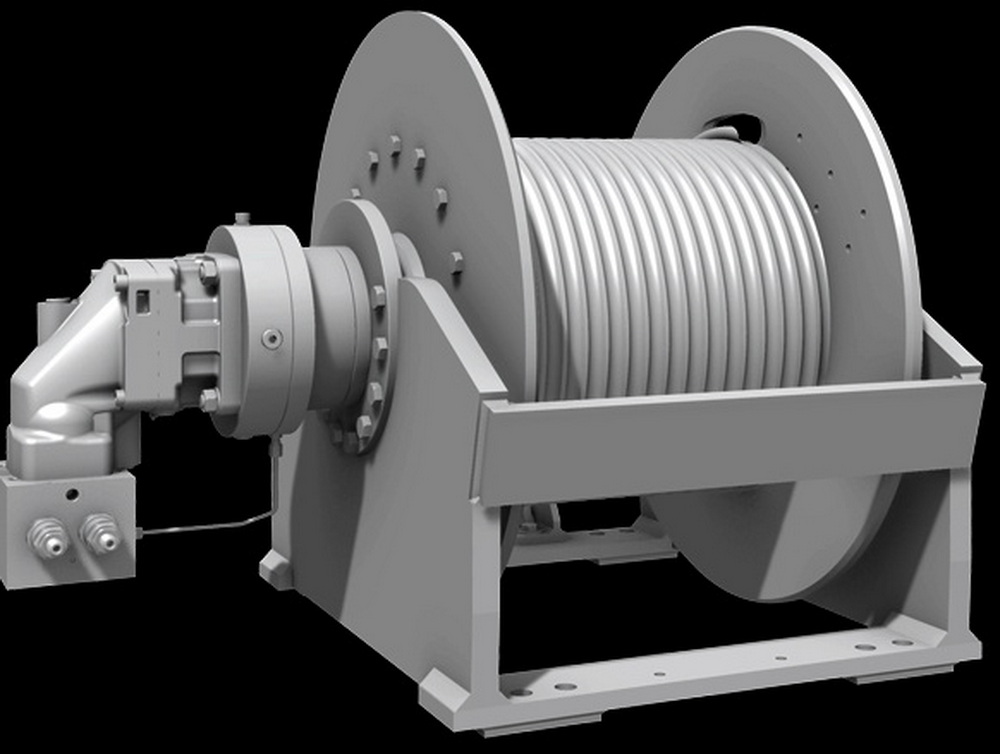

A hydraulic winch is a heavy‑duty pulling and lifting device powered by pressurized oil from a hydraulic system rather than electricity. A hydraulic winch is designed for continuous operation under high load where electric winches would overheat or struggle to maintain torque. Because many machines already have powerful hydraulic pumps and motors, a hydraulic winch is often the most efficient and reliable way to add controlled pulling and lifting capacity.[1][2]

A hydraulic winch is widely installed on ships, offshore platforms, construction equipment, mining and tunneling machinery, forestry tractors, recovery trucks, military vehicles, and fixed industrial handling systems. Across these sectors, the hydraulic winch provides controllable line pull, precise speed control, and excellent durability in harsh conditions such as saltwater, dust, mud, or extreme temperatures.[3][4]

A hydraulic winch converts hydraulic energy into mechanical pulling force using a hydraulic motor, planetary gearbox, brake, and drum assembly. Oil from a hydraulic pump flows through directional and control valves into the hydraulic motor, which rotates the drum to wind in or pay out steel wire rope or synthetic rope under load.[5][1]

Inside the hydraulic winch, a planetary gear train multiplies torque, allowing a compact drive to pull many times more than the motor's direct torque rating. The brake system, which may be a normally‑applied multi‑disc brake, holds the load safely when the hydraulic winch is stopped and can be dynamically controlled for smooth lowering. Because the hydraulic winch is integrated into the larger hydraulic circuit of the machine, it can share power with travel drives, swing drives, and other hydraulic motors.[2][1]

A hydraulic winch is chosen when users need maximum pulling power, long duty cycles, and high reliability. In many industrial and mobile applications, the hydraulic winch operates for hours at a time, supporting continuous lifting, pulling, or tensioning tasks that would overload typical electric winches.[4][6]

Major advantages of a hydraulic winch include:

- High line pull and starting torque for very heavy loads.[7]

- Exceptional duty cycle and thermal capacity for long or repeated pulls.[4]

- Smooth, fine control of speed and direction via hydraulic valves and proportional controls.[1]

- Robust performance in harsh, wet, or explosive environments where electric drives face more limitations.[4]

- Easy integration with existing hydraulic circuits on tracked machines, cranes, drilling rigs, and industrial systems.[2]

A hydraulic winch can also be configured with advanced options such as constant tension control, free‑spool mechanisms, and load‑holding valves. These features allow a hydraulic winch to maintain tension on mooring lines, synchronize with other equipment, or provide rapid rope payout when needed.[8][1]

In the marine industry, the hydraulic winch is one of the most critical deck machines on many vessels and offshore platforms. Marine environments demand equipment that can withstand saltwater corrosion, shock loading, and continuous duty under rough sea conditions, making the hydraulic winch a natural choice.[6][8]

A hydraulic winch is widely used for:

- Anchor handling and windlass systems on cargo ships, offshore support vessels, and workboats.[8]

- Mooring winches that tension and hold mooring ropes or chains during docking and station‑keeping.[6]

- Towing winches on tugboats and escort vessels, where a hydraulic winch must control high line forces safely.[9]

- Deck and crane winches for handling ROVs, subsea tools, research instruments, and heavy cargo units.[1]

Marine hydraulic winch systems often combine multiple drums, warping heads, and sophisticated control stations to manage complex line handling operations. The hydraulic winch can be integrated with automation systems to maintain constant line tension during changes in draft, tide, or vessel movement.[8][1]

On construction and infrastructure projects, a hydraulic winch is used to move and position heavy components in ways that are not always possible with cranes alone. Crawler cranes, piling rigs, drilling rigs, and bridge erection equipment frequently include a hydraulic winch as a key part of their lifting and rigging systems.[3][4]

Typical construction uses of a hydraulic winch include:

- Lifting and lowering formwork, rebar cages, and steel beams during high‑rise building work.[4]

- Pulling and tensioning cables or bridge segments during bridge launching or cable‑stayed construction.[10]

- Helping pile drivers and drilling rigs raise and position heavy tooling and casings.[11]

- Assisting with assembly and maintenance of tower cranes, including lifting booms and counterweights.[2]

Because construction conditions constantly change, the controllability of a hydraulic winch helps operators adjust line speed and tension to match site requirements. The hydraulic winch can be configured with radio or remote control systems to keep personnel away from suspended loads and hazardous areas.[10][1]

Mining, quarrying, and tunneling operations require rugged equipment that can handle abrasive dust, shock loads, and confined working spaces. In these environments, a hydraulic winch is preferred because it delivers high pulling force with compact dimensions and has no vulnerable electric motor or large electrical cables near the working face.[12][4]

A hydraulic winch is used underground and in open‑pit mining for:

- Hoisting materials, equipment, and personnel cages in shafts and inclined drifts.[12]

- Pulling conveyor sections, crushers, and heavy equipment into service positions.[12]

- Assisting with tunnel lining placement, pipe jacking, and rescue operations.[11]

In tunneling machines and TBMs, auxiliary hydraulic winch packages can move utility lines, ventilation ducts, and backup trailers. The controlled pulling action of a hydraulic winch reduces the risk of sudden movements that might damage equipment or compromise tunnel stability.[12][4]

Forestry and logging operations rely heavily on winching to move felled timber from cutting sites to extraction points. Tractors, skidders, and purpose‑built forestry winches often use a hydraulic winch mounted at the rear or front of the machine to drag, bunch, or position logs.[9][3]

Common tasks for a hydraulic winch in forestry and agriculture include:

- Skidding logs on steep or uneven ground where direct driving is impossible.[3]

- Loading and unloading timber onto trailers or trucks in remote areas.[3]

- Recovering stuck farm machinery, such as combines or tractors, from muddy fields.[4]

A hydraulic winch offers precise modulation of pulling force, allowing operators to control log movement carefully and reduce soil disturbance. In agriculture, a hydraulic winch can also be adapted for specialized tasks such as moving irrigation lines or positioning large implements.[3][4]

Vehicle recovery and off‑road operations are among the most visible uses of a hydraulic winch. Heavy‑duty tow trucks, military recovery vehicles, and off‑road support trucks often mount a powerful hydraulic winch at the front, rear, or center of the chassis.[3][4]

Typical applications of a hydraulic winch on these vehicles include:

- Self‑recovery when the vehicle becomes stuck in mud, sand, or snow.[3]

- Recovery of other vehicles, including trucks, armored carriers, and equipment trailers.[4]

- Controlled loading of damaged vehicles onto tilt‑bed or low‑boy trailers.[3]

- Military engineering tasks such as obstacle removal, field fortification construction, and tactical bridging.[10]

A hydraulic winch is especially valuable on these platforms because it does not depend on the vehicle's electrical system and can deliver full power as long as the engine and hydraulic pump are operating. Multi‑line rigging, snatch blocks, and anchor points allow the hydraulic winch to generate very high effective line pulls in confined or difficult terrain.[5][3]

Oil, gas, and energy installations demand highly reliable lifting and pulling solutions, often in hazardous areas. A hydraulic winch is well suited to these environments because hydraulic power can be safely operated in explosive atmospheres with appropriate design and safeguards.[7][1]

In this sector, a hydraulic winch is commonly used for:

- Handling drill pipe, risers, and casing strings on offshore platforms and land rigs.[4]

- Tensioning and positioning subsea umbilicals, flexible pipes, and power cables.[6]

- Supporting maintenance work on flare stacks, derricks, and process modules.[1]

A hydraulic winch can be integrated into advanced control systems that provide constant tension, heave compensation, and synchronization with cranes or motion‑compensated equipment. These capabilities ensure loads remain stable despite wave‑induced motion or platform movement.[8][1]

Many fixed industrial and dockside facilities use a hydraulic winch as part of their permanent material handling systems. Where frequent pulling or positioning of heavy items is required, the hydraulic winch offers a compact and powerful drive that can run continuously with minimal downtime.[9][2]

Typical industrial uses of a hydraulic winch include:

- Loading and unloading heavy cargo or equipment at docks and terminals.[9]

- Positioning large machinery or modules on production lines, test rigs, and assembly stations.[2]

- Operating gates, trash racks, and maintenance platforms in dams, power plants, and water treatment facilities.[11]

By using a centralized hydraulic power unit, multiple hydraulic winch stations can be controlled independently or in coordinated groups. This makes the hydraulic winch a flexible building block for complex industrial handling systems.[1][2]

On tracked machinery and mobile equipment, a hydraulic winch is often integrated with other hydraulic drives such as travel drives, swing drives, and auxiliary hydraulic motors. The shared hydraulic power unit supplies pressurized oil to each function while valves distribute flow based on operator demand.[2][1]

The combination of hydraulic winch, planetary gearboxes, and dedicated winch drives offers several benefits:

- High torque density in a compact package for installation on crowded machine frames.[2]

- Simplified plumbing and control when using common hydraulic manifolds and valve blocks.[1]

- Improved efficiency by matching pump displacement, pressure, and flow to the machine's combined hydraulic winch and drive requirements.[9]

This integration allows OEMs to develop specialized tracked platforms where a hydraulic winch is used for pipe pulling, cable laying, equipment recovery, or positioning of work tools. The modular nature of hydraulic winch and drive packages makes it easier to scale line pull and speed for different machine sizes.[1][2]

Choosing the correct hydraulic winch for a specific application requires a clear understanding of load cases and operating conditions. Engineers and equipment builders must evaluate not only the maximum line pull but also average load, duty cycle, environmental factors, and mounting constraints.[2][4]

Key parameters when selecting a hydraulic winch include:

- Rated line pull at the available hydraulic pressure and rope layer.[2]

- Required line speed and drum rotation speed for efficient operations.[2]

- Rope diameter, length, and drum capacity, including safety wraps.[7]

- Brake type, holding capacity, and redundancy for safety.[1]

- Environmental protection such as coatings, sealing, and optional explosion‑proof design.[9]

Working with a specialized supplier of hydraulic winch systems, planetary gearboxes, and hydraulic motors helps ensure the selected hydraulic winch matches project requirements and integrates smoothly with the overall hydraulic circuit. Correct specification reduces lifecycle costs, improves reliability, and enhances operator safety.[1][2]

Safe operation of a hydraulic winch depends on proper training, well‑designed controls, and regular inspection. Operators should understand line pull limits, rigging principles, and the behavior of the hydraulic winch under dynamic load.[4][1]

Important safety practices for hydraulic winch use include:

- Staying clear of the rope line and potential snap‑back zones.[4]

- Using rated slings, shackles, and anchor points compatible with the hydraulic winch capacity.[4]

- Monitoring hydraulic pressure, oil temperature, and noise for signs of abnormal operation.[1]

- Inspecting rope condition, drum anchoring, and brake performance on a regular schedule.[1]

Modern hydraulic winch systems may incorporate overload protection valves, pressure relief, load indicators, and remote control systems to enhance safety. These features help prevent excessive line tension and allow operators to control the hydraulic winch from a protected location.[10][1]

Regular maintenance keeps a hydraulic winch ready for demanding work and extends its service life. Maintenance requirements vary with duty cycle and environment, but generally follow similar principles across industries.[2][1]

Key maintenance tasks on a hydraulic winch include:

- Checking hydraulic hoses, fittings, and seals for leaks or damage.[1]

- Monitoring hydraulic fluid cleanliness and replacing filters as recommended.[1]

- Inspecting wire rope or synthetic rope for wear, corrosion, kinks, or broken strands.[4]

- Verifying brake function and adjusting or servicing brake components as required.[1]

- Lubricating bearings and gearboxes in accordance with manufacturer guidelines.[2]

In marine and offshore environments, additional attention must be given to corrosion protection and regular flushing of exposed components. Proper maintenance ensures the hydraulic winch retains its rated capacity and minimizes the risk of unexpected failure under load.[8][1]

A hydraulic winch is used on a wide range of equipment, including ships, offshore platforms, construction cranes, mining systems, forestry machines, recovery vehicles, and industrial handling installations. Across these applications, the hydraulic winch delivers powerful, controllable pulling and lifting performance with excellent duty cycle and durability in harsh conditions.[3][4]

By integrating hydraulic winch solutions with tracked undercarriages, planetary gearboxes, travel drives, winch drives, swing drives, and hydraulic motors, equipment manufacturers can create compact and efficient machines tailored to demanding tasks. Correct selection, safe operation, and regular maintenance of each hydraulic winch ensure long‑term reliability, higher productivity, and better safety on job sites and at sea.[2][1]

A hydraulic winch is most commonly installed on marine vessels, offshore platforms, construction machinery, mining equipment, forestry tractors, recovery trucks, and industrial handling systems. Any machine with a suitable hydraulic power source and structural mounting points can usually be equipped with a hydraulic winch tailored to its duty.[3][2]

A hydraulic winch is preferred when high line pull, long duty cycles, and harsh conditions are expected, because hydraulic drives manage heat and load more effectively than many electric systems. A hydraulic winch can run for extended periods and integrate easily with other hydraulic functions on the same machine, improving overall efficiency.[4][1]

A hydraulic winch is widely used offshore and can be adapted for subsea work when equipped with suitable sealing, materials, and corrosion protection. Because the hydraulic motor and valves can be designed for wet conditions and hazardous areas, a hydraulic winch is often favored over electric winches on offshore platforms and marine vessels.[6][1]

A hydraulic winch on heavy equipment requires routine inspection of hoses, fittings, rope, and structural mounting, as well as regular lubrication and fluid maintenance. Brake testing, load testing, and cleanliness control of the hydraulic system are essential for keeping the hydraulic winch safe and reliable throughout its service life.[2][1]

A hydraulic winch improves safety by providing smooth, precise control of load movement and reliable braking, which helps prevent sudden shocks and uncontrolled motion. Many hydraulic winch systems include overload protection, remote controls, and load monitoring features that allow operators to stay out of danger zones while maintaining accurate control.[10][1]

[1](https://www.ini-hydraulic.com/news/how-hydraulic-winches-work-and-their-applications)

[2](https://www.hydrauvision.com/en/products/hydraulic-winches/)

[3](https://www.winchhire.co.uk/the-most-common-applications-for-hydraulic-winches/)

[4](https://garlway.com/faqs/what-are-the-common-applications-of-hydraulic-winches)

[5](https://apollooffroad.com/blogs/default-blog/blog-how-does-a-hydraulic-winch-work)

[6](https://aicraneliftingsolution.com/winch/hydraulic/)

[7](https://garlway.com/faqs/what-are-hydraulic-winches-used-for-and-what-industries-commonly-use-them)

[8](https://www.bloommfg.com/blog/post/everything-you-need-to-know-about-marine-hydraulic-winches)

[9](https://www.horydrive.com/news/hydraulic-winch-applications-85180264.html)

[10](https://www.linkedin.com/pulse/hydraulic-winch-drives-real-world-5-uses-youll-9al8c)

[11](https://www.apollohoist.com/company-news-2/the-structure-and-scope-of-use-of-the-winch/)

[12](https://cpwinch.com/a-complete-guide-to-mining-winches-and-their-applications/)

Top Rubber Track Undercarriage Manufacturers And Suppliers in Thailand

Top Rubber Track Undercarriage Manufacturers And Suppliers in Malaysia

Top Rubber Track Undercarriage Manufacturers And Suppliers in South Korea

Top Rubber Track Undercarriage Manufacturers And Suppliers in Kazakhstan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Georgia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Philippines

Top Rubber Track Undercarriage Manufacturers And Suppliers in Azerbaijan

Top Rubber Track Undercarriage Manufacturers And Suppliers in Armenia

Top Rubber Track Undercarriage Manufacturers And Suppliers in Iran

Top Rubber Track Undercarriage Manufacturers And Suppliers in Turkey